ABOUT USMore

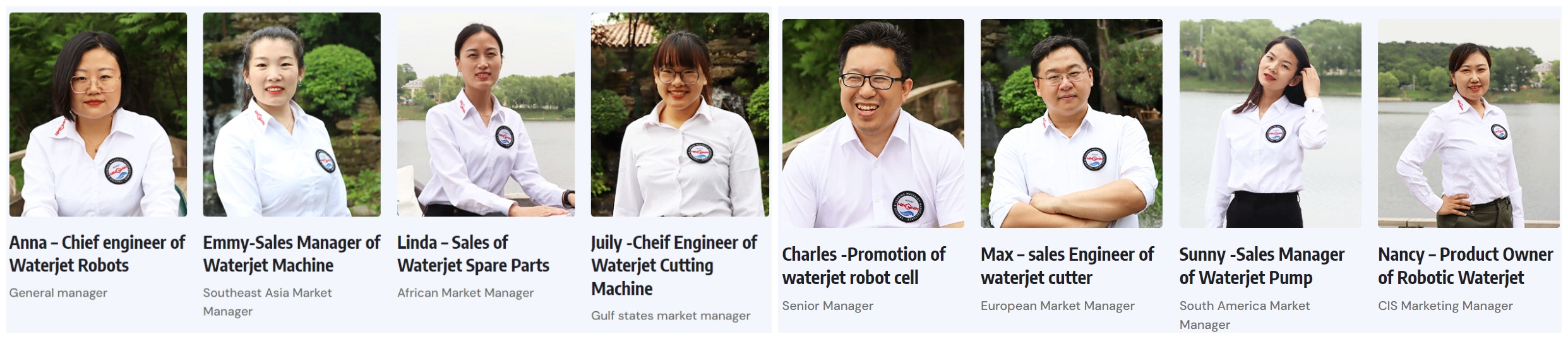

Win-Win Waterjet is a leading manufacturer and supplier of waterjet machines, focusing on providing customers with high-quality waterjet cutting solutions.

Win-Win Waterjet specialises in research and development and manufacture of advanced waterjet cutting machines and related Waterjet spare parts. Our products are widely used in various industries, including automotive , chemical industry, aerospace, construction, metal processing, electronics, glass industry, etc.

Win-Win Waterjet has developed different solutions as below:

1. Pure waterjet robot for automotive interiors

2. Abrasive Waterjet robot for cutting helmets

3. Cleaning and stripping oil pipelines with Ultra-high pressure Waterjet pump

4. 8000*4000mm super large platform heavy industrial metal water cutting solution

5. Multi-waterjet cutting head paper cutting solution

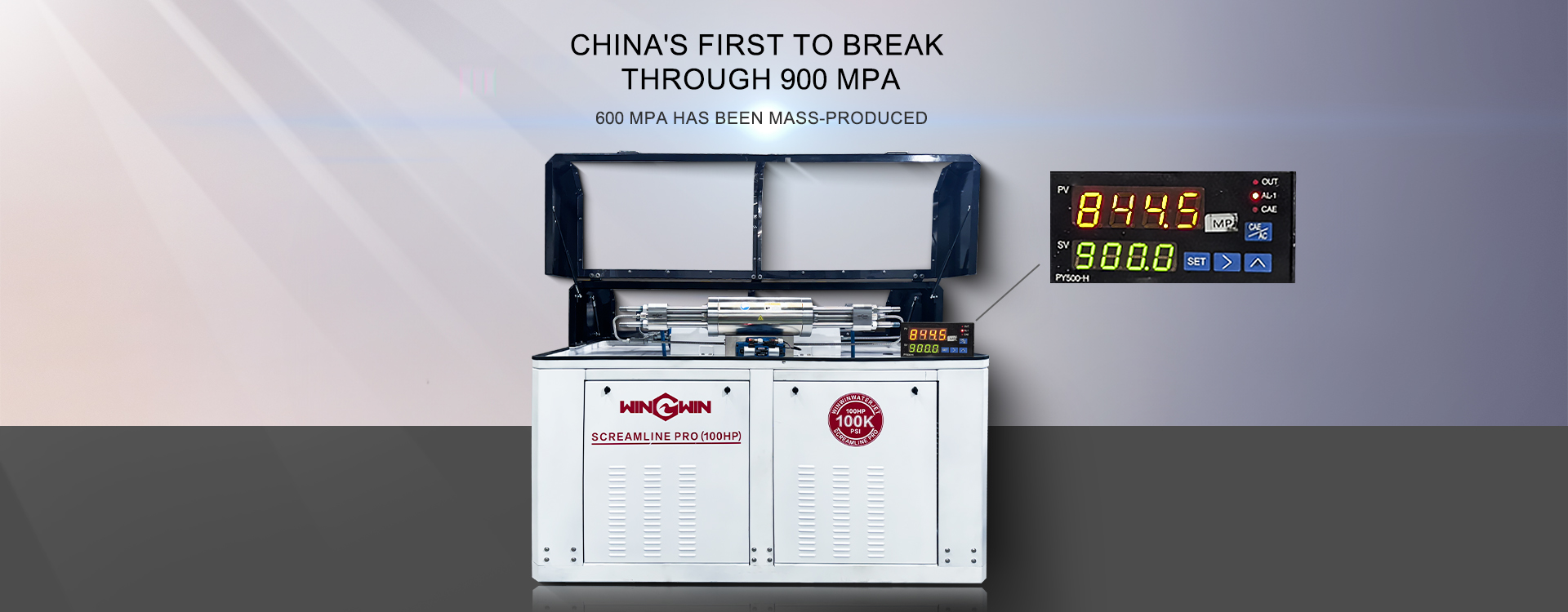

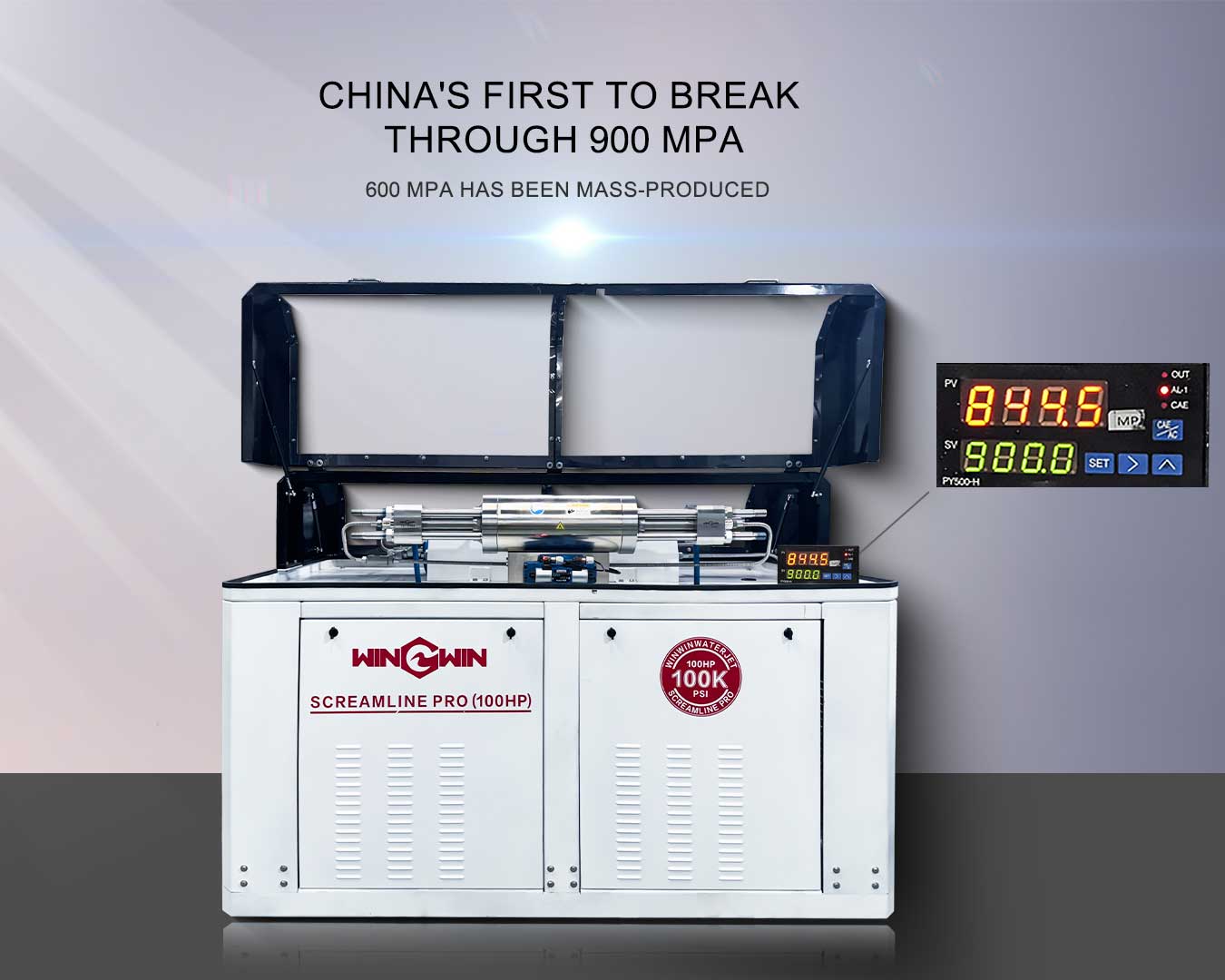

6. 100,000psi/6200Bar ultra-high pressure waterjet ultra-thick metal solution

If you are interested in our products or services, please feel free to contact us

Our Partners

FAQs

How to reduce noise during robotic waterjet work?

How to reduce noise during robotic waterjet work?

Specification

| Robot arm | ABB IRB1600-20KG |

| Structure | Full enclosed Ceiling type |

| Table | Turn table |

| Is there a soundproofing structure? | Yes |

| Pump | Waterjet SL-VI dual intensifier waterjet pump |

1. Enclosure or Soundproofing:

Build an enclosure around the robotic waterjet cutting machine to contain the noise within a confined space. Use materials with

sound-absorbing properties, such as acoustic panels or foam, to minimize noise transmission. Ensure the enclosure has proper ventilation to prevent overheating.

2. Vibration Isolation:

Install anti-vibration mounts or pads beneath the robotic waterjet cutting machine to reduce the transfer of vibrations to the surrounding structure.

This can help minimize noise propagation.

3.Maintenance and Calibration:

Regularly maintain and calibrate the robotic waterjet cutting machine to

Roctec 500 Nozzle Waterjet spare parts

Roctec 500 Nozzle Waterjet spare parts

What is Roctec?

ROCTEC composite carbide is a tungsten carbide-based material made by the patented Rapid Omnidirectional

Compaction (ROC) process exclusive to Kennametal.

What is the difference between Roctec 100 and Roctec 500?

Roctec 500 Improved cutting accuracy and tolerance levels vs the ROCTEC 100. Less machine downtime and longer

nozzle lifespan compared to ROCTEC 100 and tungsten carbide/cobalt mixing tubes.

What is the lifespan of a waterjet nozzle?

and the usage conditions. Misusing the nozzle can significantly degrade its performance and provide a lower lifespan

8000x4000mm Large Format Waterjet cutting machine

8000x4000mm Large Format Waterjet cutting machine

Cutting table size: 8000x4000mm

Axis: 5axis waterjet cutting head

It has a cutting area of 4 meters by 8 meters), making it suitable for cutting large sheets of material. This machine is designed for industrial use and can

handle various materials such as metal, stone, glass, and composites.

What factors should be considered before purchasing a large platform

waterjet cutting machine ?

When selecting a large-scale waterjet cutting machine, there are several key factors to consider. Here are some important aspects to keep in mind:

Cutting Area:

Determine the size of the cutting area required for your specific applications. Consider the largest dimensions of the materials you'll be working

with and ensure the machine's cutting area can accommodate them

Precision and Accura

Can do OEM/ODM for waterjet cutting machine ?

Yes, no problem. We have 20 years of experience in water jet cutting and have our own R&D, design and production team. We can design and produce water jet cutting equipment according to customer needs

What the robot waterjet cutting station can do ?

Robotic waterjet cutting solutions combine the versatility of waterjet with the smart manufacturing power of automation, increasing manufacturing flexibility, capacity, and output. Highly recognized as the most versatile material processing solution, waterjet cuts virtually any material, any shape – with ease. From 2-dimensional flat stock to 3-dimensional molded components, metals to fabric, plastic composites, and food, waterjet is an effective, efficient cutting solution.

What are the advantage of 90000 psi waterjet ?

The advantages of 90,000 psi waterjets are lower abrasive usage and faster cutting speeds. Faster cutting speeds reduce the inputs of electricity usage, operator labor, and shop overhead. The graph below shows the total costs for the lifetime of each system in equivalent cutting.

What about installation and training for waterjet cutting machine ?

Through video guidance, we can complete the installation work. If the customer needs, we can also take pictures of technical personnel for on-site installation and debugging, and provide training to the customer

How long is your delivery time for waterjet cutting machine ?

It depends on the model of the equipment. Generally speaking, it will be delivered after the completion of production and testing, and the time is 15-30 working days

wwaterjet

wwaterjet