What kind of materials can win-win waterjet cut ?

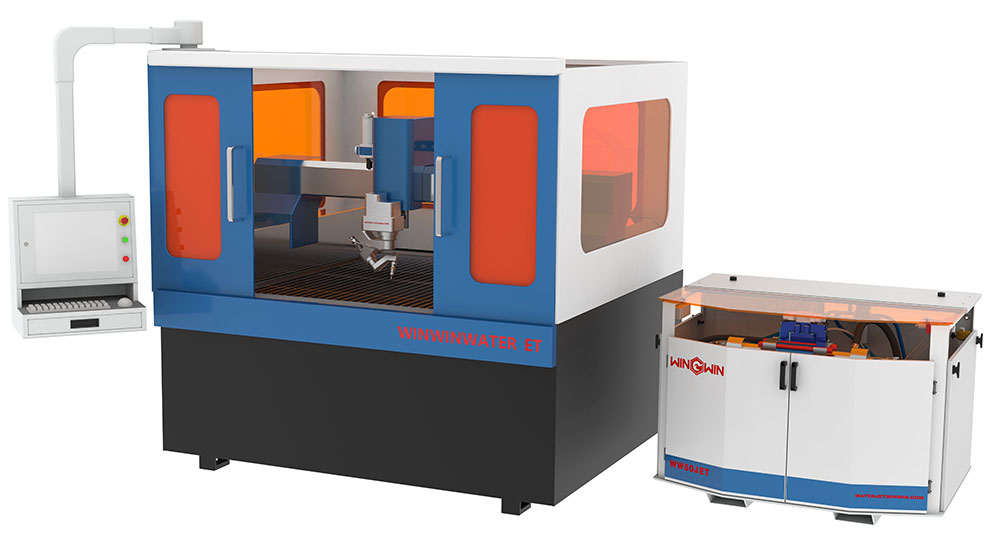

Win-Win Metal Cutting waterjet Systems

Waterjet tables can be used to cut thicker metals than can be processed with a laser – like titanium and aluminum

(up to 12”/305mm)– and offer greater precision than plasma cutting. Abrasive waterjet systems are also less expensive

than laser solutions, making them a solid choice for metal and steel cutting in the fabrication industry.

|  |

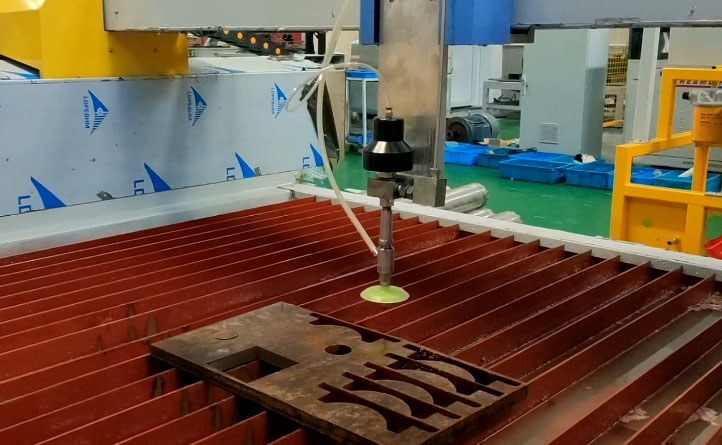

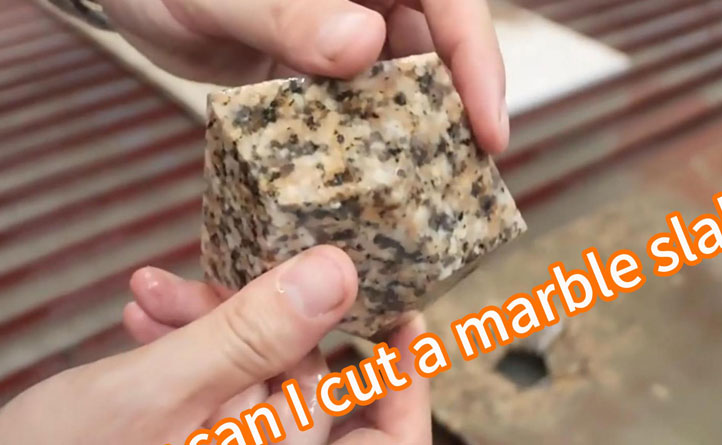

Waterjet Cutting for Stone & Tile

Waterjet machines using the Win-Win Waterjet pumps are perfect for creating corporate logos in decorative

designs on walls or inlaid into floors, countertop parts, faucet and sinkholes as well as a smoother radius off

sharp edges of slabs cut with saws.

Ideal for Job Shop owners, stone cutting, marble cutting, granite cutting and Tile can all be fabricated by

designers, for nontraditional “zero gap” cutting circular, square, oval, tile rugs, stone rugs, borders, murals,

entry ways, kitchens, bathrooms, octagon patterns, medallion designs, border and accent tiles, polished,

unpolished and textured porcelain.

|  |

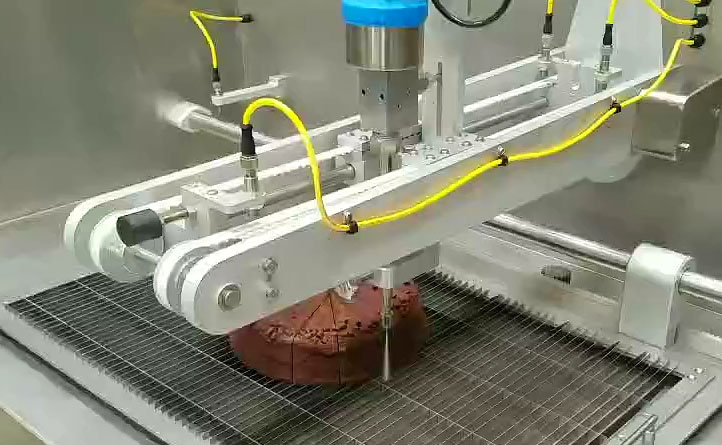

Waterjet Cutting Food

water jets have been used as a manufacturing process to cut variety types of food cutting,

including pizza, cakes, romaine lettuce, celery, meats, frozen fish, bacon, sandwiches, pettit fours,

candy bars, granola bars and all types of frozen food. Pure water cutting up to 90,000 PSI/6,200 bar

offers the greatest added value by cutting produce, meats, bakery, and confection products in a

sanitary environment without the cross contamination found in blade cutting systems.

Meet Our Food Cutting OEMs

|  |

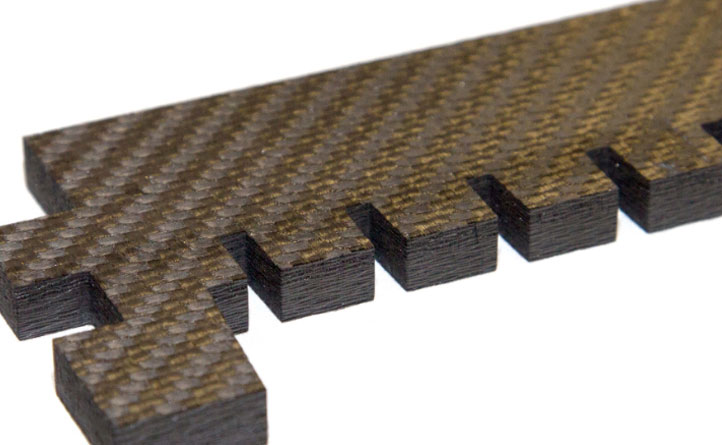

Win-Win Waterjet cutting Composite

Because composites are not homogenous materials and are reinforced for greater strength, cutting

composites requires a different approach than ceramic cutting or metal cutting, for example. Using

conventional cutters and machining techniques will quickly cause parts to wear out and require

replacement. Employing the techniques often used for cutting granite or titanium may also compromise

the strength of the composite and/or cause delamination, making the material less suitable for use in

applications such as aircrafts and medical devices.

|  |

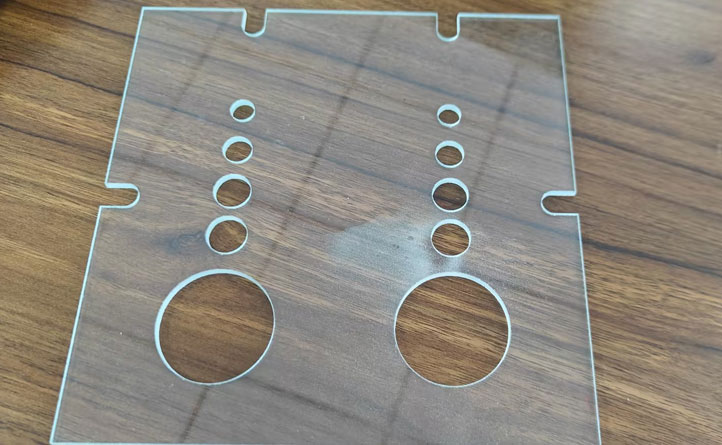

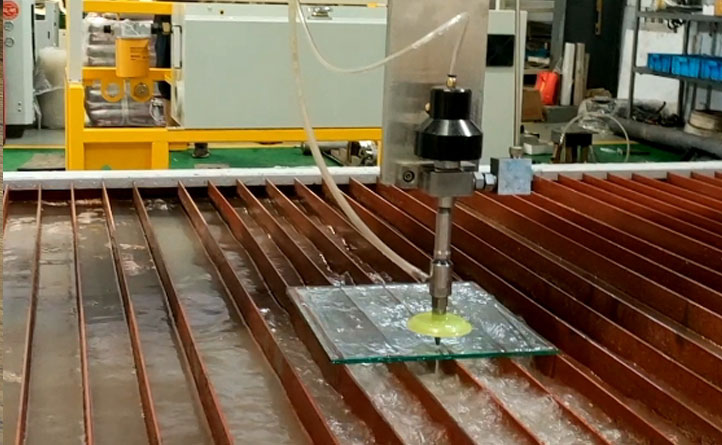

Win-Win waterjet Cutting Glass

Abrasive waterjet cutting technology is a great method for cutting glass because it allows for contours

and shapes that cannot be achieved with other cutting machines at a reasonable cost. From artistic

tabletop inlays to detailed stained glass designs, mirrors, glass ornaments, replacement windows for

antique cars, and more, there’s almost no glass cutting application* that a waterjet cutting machine

from win-win Waterjet can’t tackle. *(Not suitable for the processing of tempered or hot glass)

Glass has a tendency to crack, so it is very important that the initial holes are produced with a reduced

pressure of 7,200 PSI/500 bar to 11,600 PSI/800 bar. Subsequently, the pressure must be increased to a

cutting speed that is cost-effective. For glass, ceramics and other brittle materials, you must gradually

increase and reduce the cutting pressure by means of proportional pressure control of the intensifier

pump, otherwise the material would be destroyed.

|  |

Plastic and Acrylic Cutting with Waterjet

Water jet cutting technology has been used for several decades to perform plastic and acrylic cutting.

In fact, this process supersedes the development of the abrasive waterjet used to cut harder materials

such as stone, glass, and metals. Unlike abrasive waterjet cutting, however, only pure waterjet is used

to cut plastics and acrylics.

The clean, very thin waterjet stream (thinner than a strand of human hair) does not cause the material

being cut to absorb water, maintaining the integrity of the materials. The technology also does not create

heat-affected zones while precisely cutting with speed. Waterjet leaves a smooth, clean cut, virtually

eliminating and second operation for finishing. Thus, the efficiency of the process makes cutting with

water jets an effective solution for manufacturers of plastic and acrylic components and parts.

Paper Cutting & Slitting with Waterjet

Water jet cutting technology has been used for several decades to perform paper cutting. In fact, this

process supersedes the development of the abrasive waterjet used to cut harder materials such as stone,

glass, and metals. Unlike abrasive waterjet cutting, however, only pure waterjet is used to cut paper and foods.

The clean, very thin waterjet stream (thinner than a strand of human hair) does not cause the material being

cut to absorb water, maintaining the integrity of the paper. The technology also does not create heat-affected

zones while precisely cutting with speed. Thus, the efficiency of the process makes cutting with water jets an

effective solution for paper manufacturers.

Waterjet cutting with pure water is the ideal solution for the cutting and slitting of paper and plastic webs

as well as cardboard panels. The technology is already widely used in the production of wallpaper and

packaging material.

The most common machine used in this field is called a slitter, which is a longitudinal cutting machine

equipped with one or more pure water cutting heads. The material to be cut is transferred on a conveyor

and is cut by the cutting heads located above the belt. In contrast to cutting with roller blades, the material

is not shifted and there is no dust produced in the process. As the material is in contact with the waterjet

for only a split second, its quality is not affected. The method is also suitable for the cutting of several layers

of material. In this case, the operator must ensure that there are no cavities between the layers where water

could collect.

HVAC Insulation Cutting with Win-Win Waterjet

Win-Win Waterjet cutting will help to eliminate the duct liner bottleneck in your shop while reducing the labor

associated with this process. Using conventional cutters and machining techniques will quickly cause parts to

wear out and require replacement. Employing the techniques often used for cutting HVAC duct work liners may

also compromise the strength of the insulation and/or cause delamination, making the material less suitable.

As an alternative, cutting with a water jet offers a number of benefits for HVAC rollforming machining. Win-Win

water jet intensifier pumps do not produce heat-affected zones (HAZ) or leave rough edges/burrs that require the

material to undergo secondary finishing with other cutting applications. Additionally, very little waste is created

with water jet technology to protect the material investment, and the speed of the technology makes it well suited

to high production requirements.

wwaterjet

wwaterjet