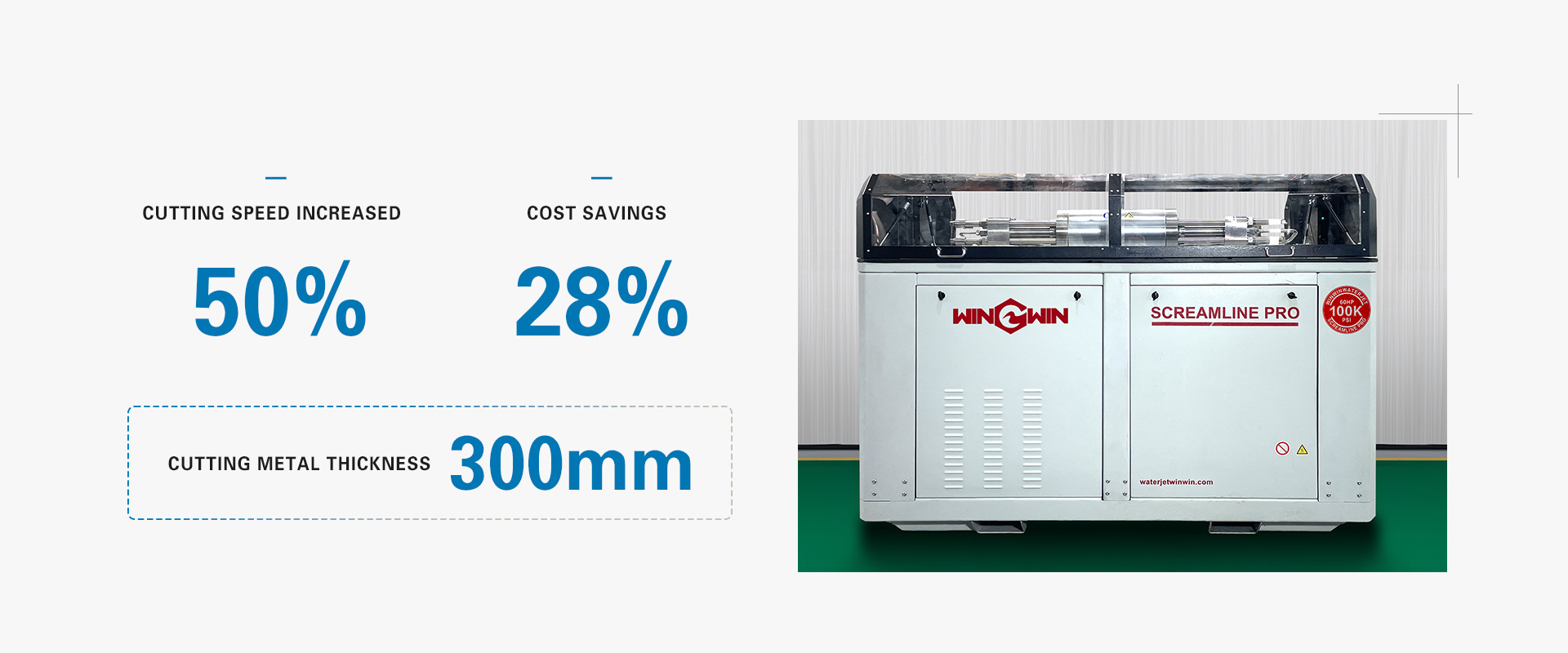

100000PSI Dual Intensifier Waterjet Pump waterjet systems

Our Screamline Pro 100000PSI Dual Intensifier Waterjet Pump and servo system ultra-high pressure pumps represent the new quality standard of WIN-WIN waterjet system. The newly designed end bell hard seal (HSEC) pressure intensifier determines the trend of the waterjet industry. SCREAMLINE PRO standard type and servo type can help you provide ultra-high pressure for pure water and abrasive cutting applications, no matter how your system is designed: the standard type and servo type of SCREAMLINE PRO can be installed and operated independently, or can be operated remotely through any central control system.

Long service life seals guaranteed for 500 hours (Terms & conditions apply)

Metal-to-metal seal design is more durable with no wear in the high pressure cylinder bore

Tie Rod Design with hydraulic loading tensioner guarantees longer lifetime of seals

Stainless steel liner adds extra protection to ceramic plunger for longer life

Brand | WINWIN | Model | Scremlin Pro |

Name | 100,000psi waterjet pump | Temperature | 5-40°C |

Pressure Range | 100,000psi | Oil Level and Temperature Control | Sensor |

Low Pressure Filter | 10 µm abs. | Application | Water jet cutting system |

Voltage | 380V | Rated power | 60hp (45kw) |

Attenuator capacity | 2L | Nom. Current at 480V/60Hz (Full Load Amp) | 70 A |

| Maximum water flow | 0.78 gal/min (2.9 lpm) | Min. Cutting Water Inlet Flow | 4.0 gal (15.1 L) |

Hydraulic Tank Capacity | 220L | Size (L * w * h) | 2.2m*1.4m*1.5m |

Application of 100000PSI Dual Intensifier Waterjet Pump waterjet systems

100000PSI Dual Intensifier Waterjet Pump waterjet systems used for Manufacturing and Materials Processing:

Ultra-high pressure waterjet cutting and machining - Allows precision cutting, trimming, and shaping of extremely hard materials like titanium, Inconel, ceramics, and advanced composites.

Waterjet depainting and surface preparation of metals, composites, and other materials.

Waterjet cleaning and descaling of industrial parts and equipment.

Automotive and Aerospace:

Waterjet cutting of automotive body panels, trim, and interior components made from advanced materials.

Waterjet trimming and shaping of aerospace composite structures, like aircraft wings and fuselage panels.

Waterjet cleaning and surface preparation of engine components and other parts.

Defense and Military:

Waterjet cutting of armor plating, ballistic glass, and other advanced protective materials.

Waterjet disassembly and demolition of military vehicles, ordnance, and other equipment.

Waterjet cleaning and surface preparation of weapons, vehicles, and other military hardware.

Construction and Infrastructure:

Waterjet demolition and removal of concrete, stone, and other rigid building materials.

Waterjet cleaning and surface preparation of bridges, dams, and other infrastructure.

Research and Development:

Enabling advanced materials research under extreme pressures to study their properties and behavior.

Applications in fields like geophysics, astrophysics, and chemistry that require recreating very high pressure environments.

wwaterjet

wwaterjet