Coating Removal with Waterjet for Aero Engines & IGT

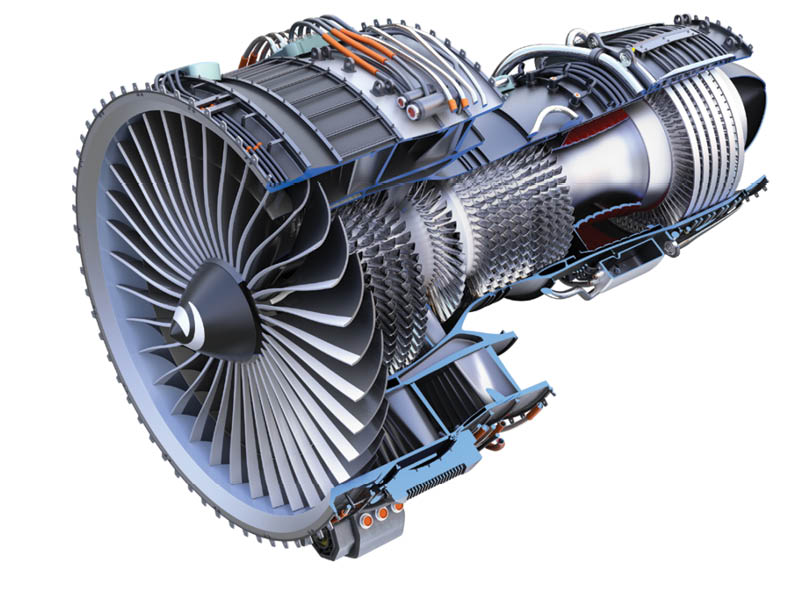

Many aero-engine and industrial gas turbine components, such as turbine blades and combustor liners,

are subject temperatures up to 2000°C. Heat this severe requires thermal barrier coatings to be applied in

order to maintain optimal performance.

Additionally, many components are coated with abradables, wear-resistance, corrosion-protection or other

coatings, sprayed or deposited using various processes: Plasma Spray, HVOF, EB-PVD, and more. These aim

at extending lifetime between repair or replacement, improving engine performance, or both. During regular

repair intervals, these important coatings must be removed before components are repaired, and then re-applied

before the component is entered back into service.

Waterjet is the optimal solution to remove these coatings efficiently, safely, and in a cost-effective manner.

Ultrahigh Pressure Waterjet Stripping

Our coating removal solution is the preferred method for removing thermal barrier coatings quickly,

while maintaining the overall structural strength of the part. The Aero Engines and IGT improve their

processes with waterjet stripping.

If you want remove these coatings ,please feel free contact win-win waterjet

wwaterjet

wwaterjet