WIN-WIN waterjet cutting machine cantilever waterjet working platform is integrally processed by a large 5-axis CNC machining center. Both X-axis and Y-axis girder adopt the double-layer dustproof and waterproof structure and are driven by high-quality ball screw guide rails and bus CNC system.

This is one of waterjet cutting machines we customize for our steel customers . This customer is known as the King of Steel in his country.

How much thickness of material can the Abrasive waterjet cutting machine cut?

The cutting thickness of WINWIN waterjet cutting machine can reach up to 300mm (steel). The cutting thickness is determined by the hardness and density of the material. The greater the hardness and density, the smaller the cutting thickness.

The cutting thickness is also related to the intensifier pump of the waterjet. The quality of the intensifier pump directly affects the cutting quality, cutting thickness, cutting speed and other factors of the waterjet.

So how to choose a suitable intensifier pump is the top priority. The customer knows that WIWNIN is the first manufacturer in China to put 90,000psi ultra-high pressure equipment into production. It has rich experience in ultra-high pressure equipment, so he proposed to us this according to the requirements, the cutting size of the platform is 4m*2m, and it can automatically load and unload materials. We have provided a set of design solutions for customers.

Advantages & Features of this waterjet cutting machine

Ground loading platform

The cutting table adapts latest loading design, the max load-bearing is 1000 kg, Equipped with a floor-standing turning platform point, which can automatically load and unload materials from three directions.

Floor-type loading system for large piece of material cutting of 4 meters * 2 meters

Hydraulic lifting and some other designs can meet the requirement of metal cutting

Cantilever structure

Cantilever structure, cutting platform and operating platform are designed to be separated to avoid the overall deformation of the waterjet cutting machine due to the influence of the water tank load. The water tank WINWIN is made of 6mm thick steel plate. The equipped grid width is 80cm. It adopts an adjustable structure to make it more convenient for customers to use.

Good stability and guaranteed lifespan

The entire machine adopts a fully protective structure made of stainless steel, so it can work stably in any complex environment. The X-axis material of the water cutting machine platform is an aluminum alloy profile, which has high strength, is light in weight, and will not be permanently deformed. The Y-axis of the cutting machine platform uses a linear guide structure, which can ensure the stability of operation. The linear guide rail of large platforms is more stable than the screw structure.

| Series | 5A-4020 Water Jet | Type | Cantilever Type |

| Cutting Precision | ±0.1mm | Control Accurcy | ±0.01mm |

| RE-Positioning Accuracy | ±0.05mm/m | Travel Of Z Axis | 200mm |

| Cutting Speed | 11000mm/min | Motor | 30kw / 40HP |

| Table Size | 4000mmx2000mmx200mm | Certificate | CE ISO |

WIN-WIN Ultra High Pressure 90,000psi Pump

Our 90,000psi standard and servo system ultra-high pressure pumps represent the new quality standard of WIN-WIN waterjet cutting machine. The newly designed end bell hard seal (HSEC) pressure intensifier determines the trend of the waterjet industry.

SCREAMLINE PRO standard type and servo type can help you provide ultra-high pressure for pure water and abrasive cutting applications, no matter how your system is designed: the standard type and servo type of SCREAMLINE PRO can be installed and operated independently, or can be operated remotely through any central control system.

1.UHP intensifier pump to achieve ultra-thick material cutting

2.Up to 300mm metal thickness

3.Efficient cutting, saving 40% of time

Cutting with win-Win's abrasive garnet for waterjet cutting machine

WINWIN has a dedicated sand factory to produce high-quality 80 mesh garnet. Every time customers purchase WINWIN's sand, they purchase several containers, because high-quality sand can not only increase the cutting speed, but also improve the cutting accuracy and make the cut surface smoother. Smooth and no limit on the thickness of the cutting material

Since our customers are cutting 300mm ultra-thick metal, not only the thickness of the material is high, but also the hardness is high, and more importantly, it is used for a long time under ultra-high pressure of 90,000psi, ultra-high pressure 90,000psi machine is matched with the highest quality abrasive under this working pressure.

The above is the introduction of this set of cantilever structure water cutting machine. The choice of cantilever structure and gantry structure is also an aspect that many customers are concerned about. What is the difference between these two structures?

In fact, there is no difference between them in the size of the cutting material, the type of material processed, and the cutting head equipped. However, the water jet cutting machine with a cantilever structure is more convenient in loading materials. In addition, it also has the following features:

Cantilever operation is more convenient and easy to use;

Split structure has lower long-term maintenance costs than one-piece structureThe transmission system has a long service life away from the cutting area.

The transmission parts have little wear, high precision and good cutting consistency.Because it is open laterally, a rotating mechanism can be easily installed on the workbench.

Waterjet cutting machines play an irreplaceable role in pillar industries of the national economy such as engineering machinery, energy, transportation, steel metallurgy, automobile manufacturing, and electronic and electrical industries.

Common types of waterjet cutting machine in industry include: robotic waterjets, abrasive waterjet cutting machine, and portable waterjets.

Choose different models according to different operating environments, such as outdoor oil tank demolition, ore removal in tunnel mining areas, abandoned cement columns mixed with steel bars at construction sites, etc. Portable water cutting can be used.

Car carpets, complex 3D processing, car dashboards, and ship composite panels can be drilled and drilled using robotic waterjet machines.

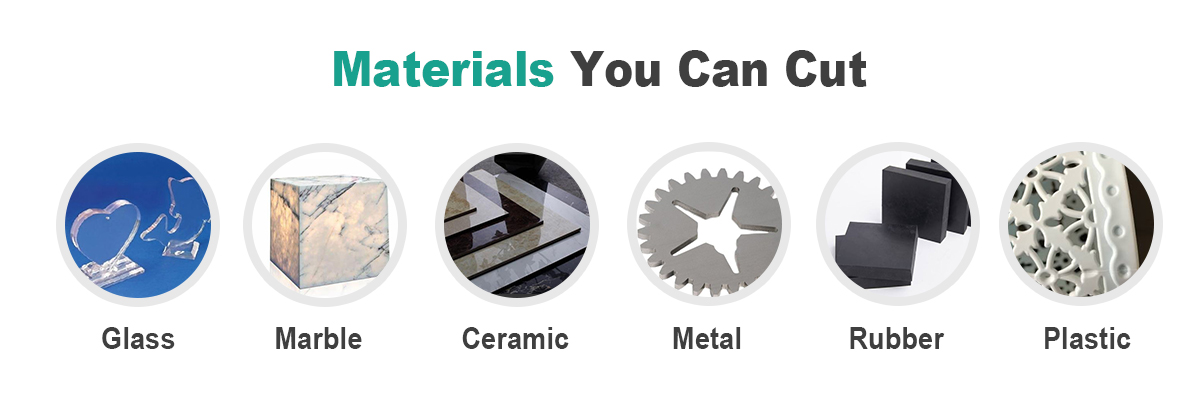

Glass, metal, marble, ceramics, alloy steel, medical special materials, circuit boards, and temperature-sensitive materials can be cut with abrasive waterjet cutting machine.

If you are interested in abrasive waterjet cutting machine,please feel free to contact us!

wwaterjet

wwaterjet