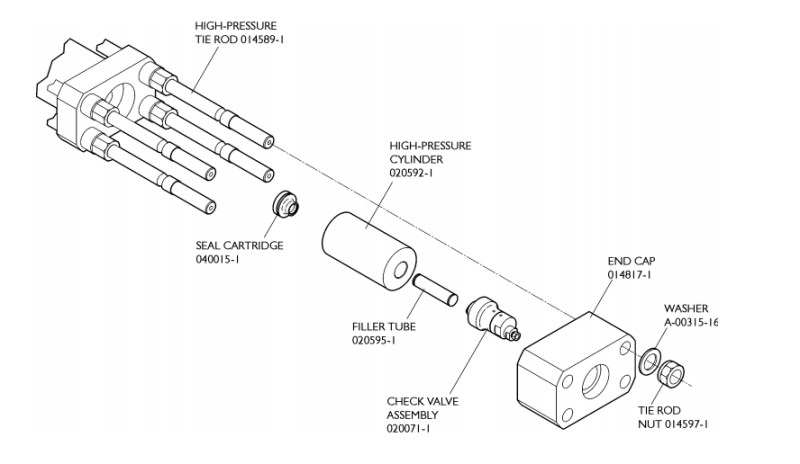

020080-1 Pision Waterjet 87K Intensifier

The intensifier pump is a complex piece of equipment that contains several key components. Here are some of the main parts that are typically found in a waterjet cutting machine intensifier pump:

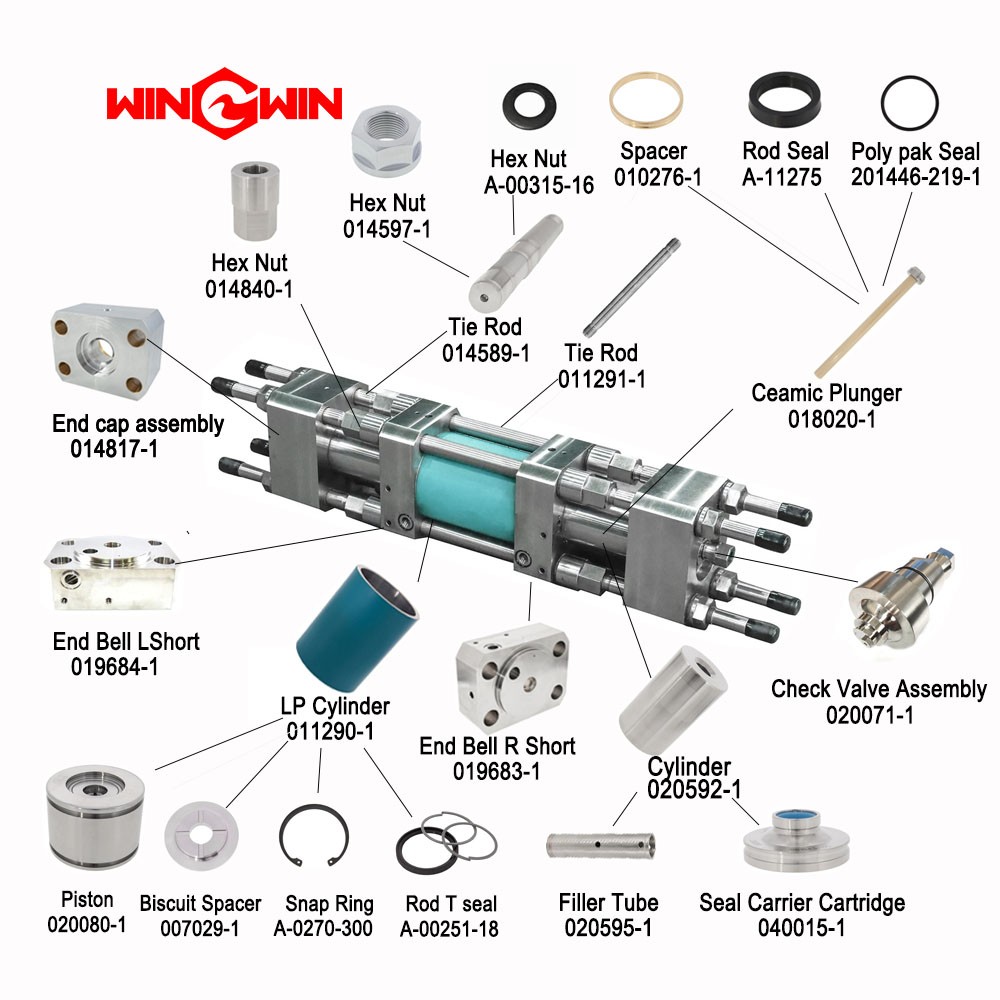

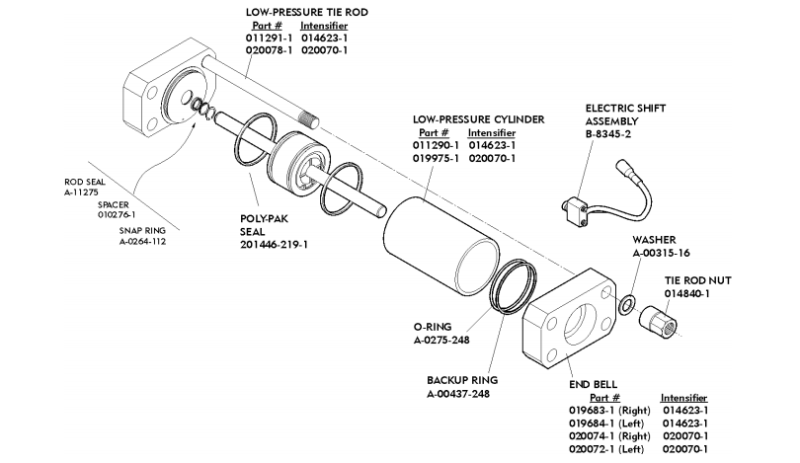

Hydraulic cylinder: The hydraulic cylinder is a component that contains a piston and a series of seals. It is responsible for compressing the water and increasing its pressure.

Plunger: The plunger is a component that moves back and forth inside the hydraulic cylinder, compressing the water and increasing its pressure.

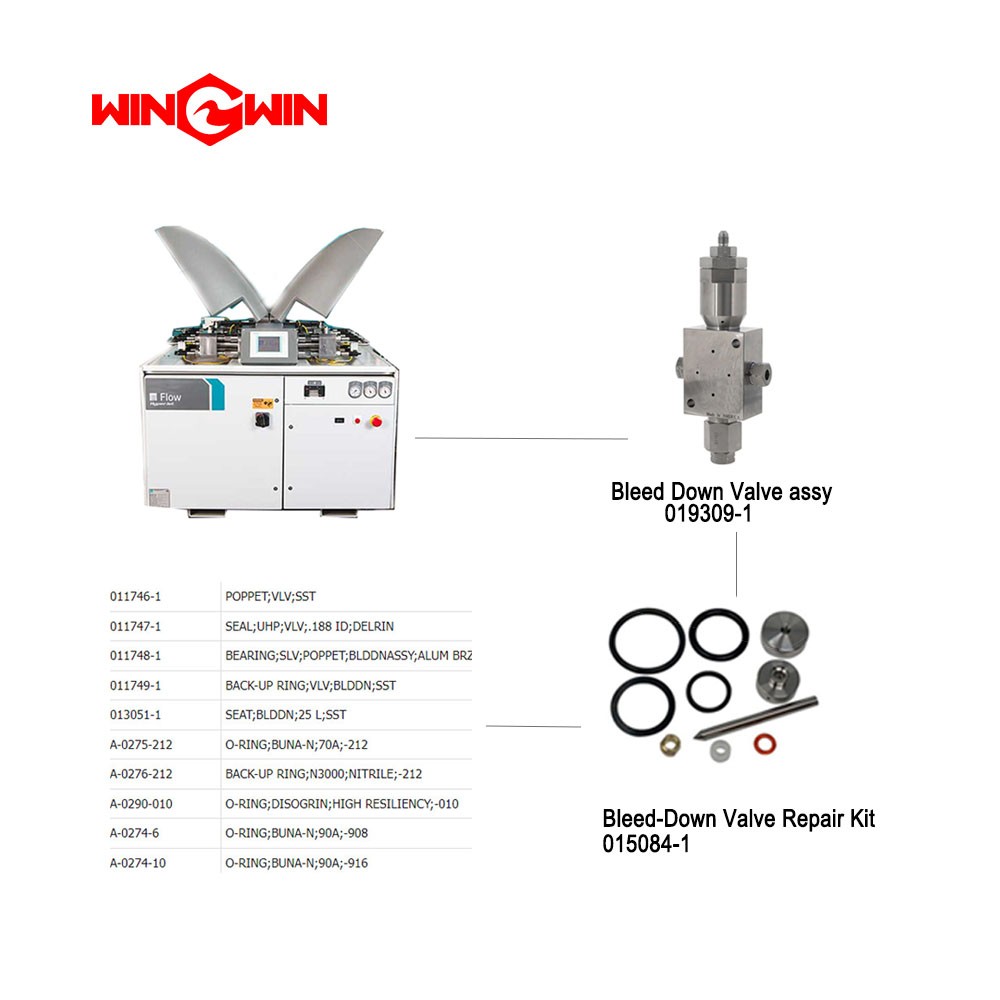

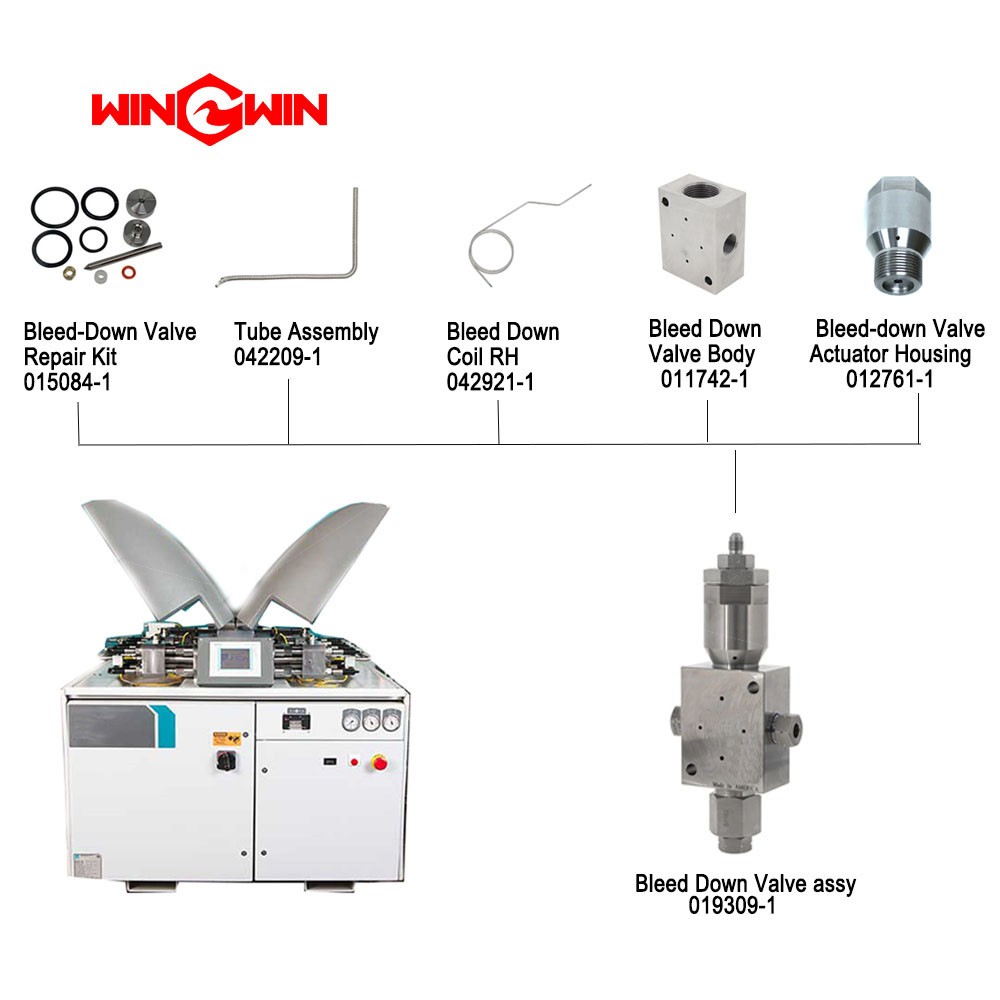

Check valve: The check valve is a one-way valve that controls the flow of water into and out of the hydraulic cylinder.

Intensifier body: The intensifier body is the main housing of the pump, which contains the hydraulic cylinder, plunger, and check valve.

Hydraulic pump: The hydraulic pump is responsible for supplying pressurized hydraulic fluid to the hydraulic cylinder, which in turn drives the plunger.

Accumulator: The accumulator is a component that stores pressurized hydraulic fluid, which can be used to maintain pressure in the system when the pump is not running.

Pressure gauge: The pressure gauge is a component that measures the pressure of the water as it passes through the pump.

Relief valve: The relief valve is a safety device that is designed to release pressure from the system if it exceeds a certain level.

High-pressure tubing: The high-pressure tubing is a series of tubes that carry the high-pressure water from the intensifier pump to the cutting head.

Water filter: The water filter is a component that removes any contaminants from the water supply before it enters the intensifier pump.

These are some of the main components that are typically found in a waterjet cutting machine intensifier pump. Each component plays a critical role in the operation of the pump, and regular maintenance and inspection of these parts is essential to ensure that the pump is operating at peak performance and to prevent costly downtime due to equipment failure.

wwaterjet

wwaterjet