The characteristics of gantry water jet and cantilever water jet

As we all know, water jet is divided into "gantry" and "cantilever", so which form of water jet is more suitable for stone manufacturers?

Advantages of gantry water jet cutting

1. Strong versatility, and almost all materials can be cut.

2. High precision, can cut accurately in any direction from multiple angles

3. After cutting, the cutting surface is neat and smooth, which will not cause any damage to the cut object in the cutting process, and can play a role in cutting operations that many cutting tools cannot achieve.

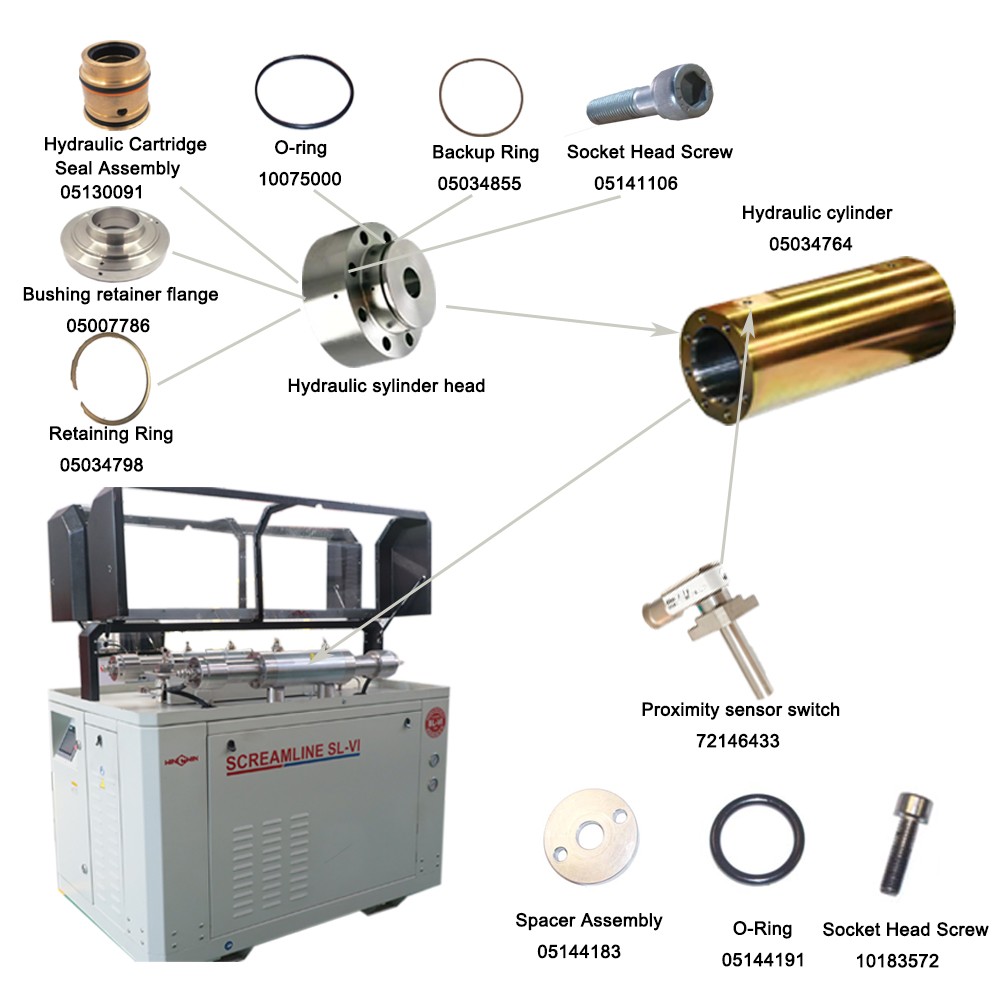

The application of water jet is very wide. So using high quality water jet spare parts is becoming very crucial.

Advantages of cantilever water jet cutting:

1. Cantilever structure, good openness, accessibility and convenient operation;

2. The cutting workbench is separated from the host machine. Even if the workbench is heated and deformed, it will not affect the accuracy of the host machine when you use WIN-WIN water jet spare parts.

3. The lead screw and guide rail of the transmission system are far away from the cutting area and have a long service life.

4. The transmission parts (lead screw or gear rack) have small wear, high precision and good cutting consistency.

5. Due to the lateral opening, the rotating mechanism can be conveniently installed on the workbench for the processing of small pipe workpieces, as shown in the above figure; Because the worktable is separated from the main machine, when necessary, the large rotating worktable can be interchanged with the plane worktable in space to realize the dual functions of pipe cutting and plate cutting.

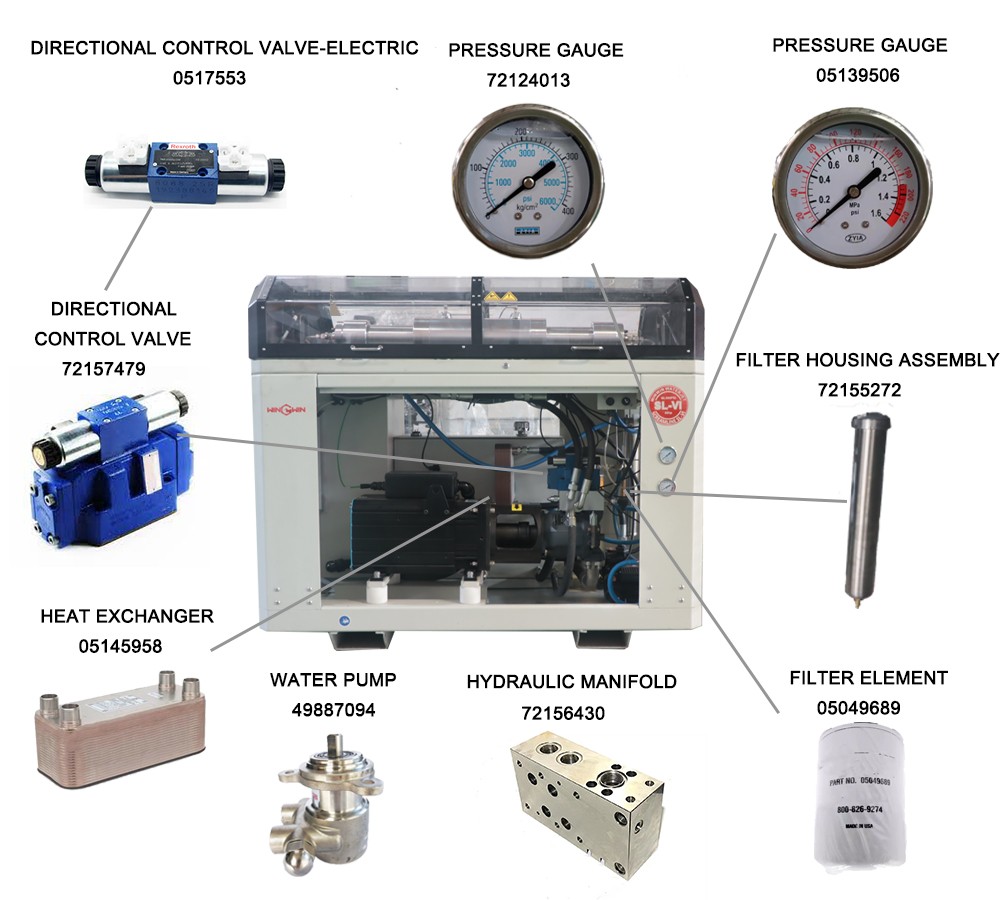

The gantry structure with movable worktable, which is often used in ultra-high pressure water jet cutting machine and water jet spare parts, is mainly composed of left and right base frames and beams, table frame and rotating fixture, driving elements, transmission system, guide rail, protective cover and other parts. The left and right foundations are frame structure, which has good stress state, good bending resistance and seismic performance; The cross beam is a box structure, with both ends supported on the guide rail and moving along the guide rail, which plays the role of fixing the water jet spare part nozzle, adjusting the target distance, controlling the plane movement of the water jet spare part nozzle and so on.

When selecting the servo motor for the ultra-high pressure water jet cutter, on the one hand, ensure that the output torque of the motor is greater than the load torque, and leave a certain margin, otherwise the motor cannot drive the load; On the other hand, it is also necessary to ensure that the transmission inertia of the motor matches the load transmission inertia and the transmission inertia of the transmission system, and leave a certain margin.

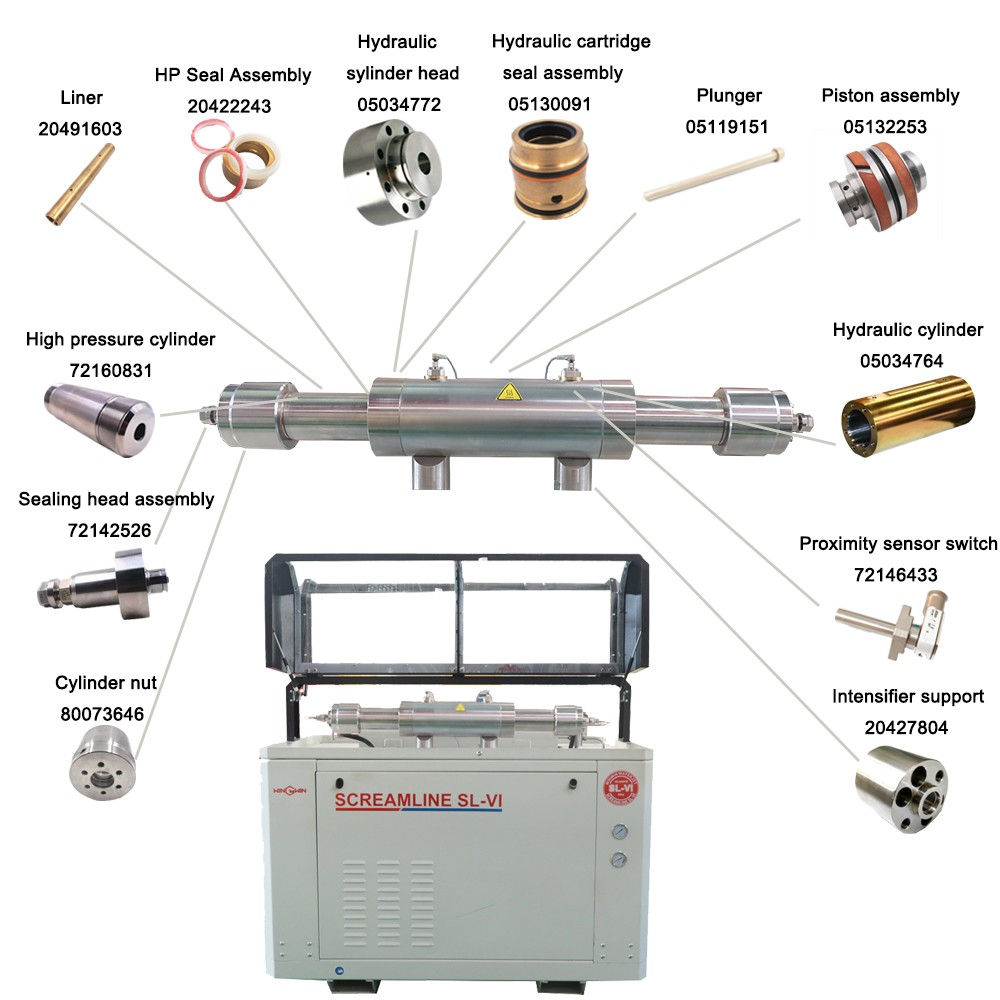

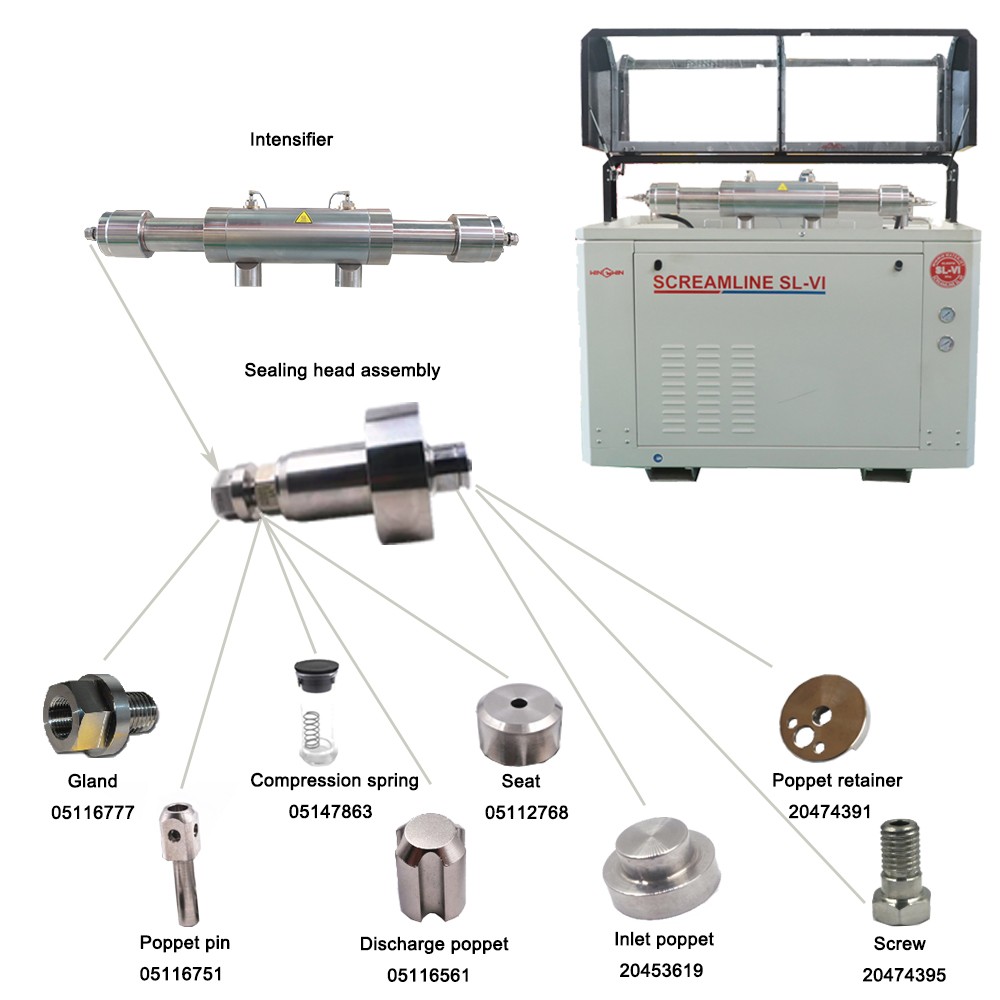

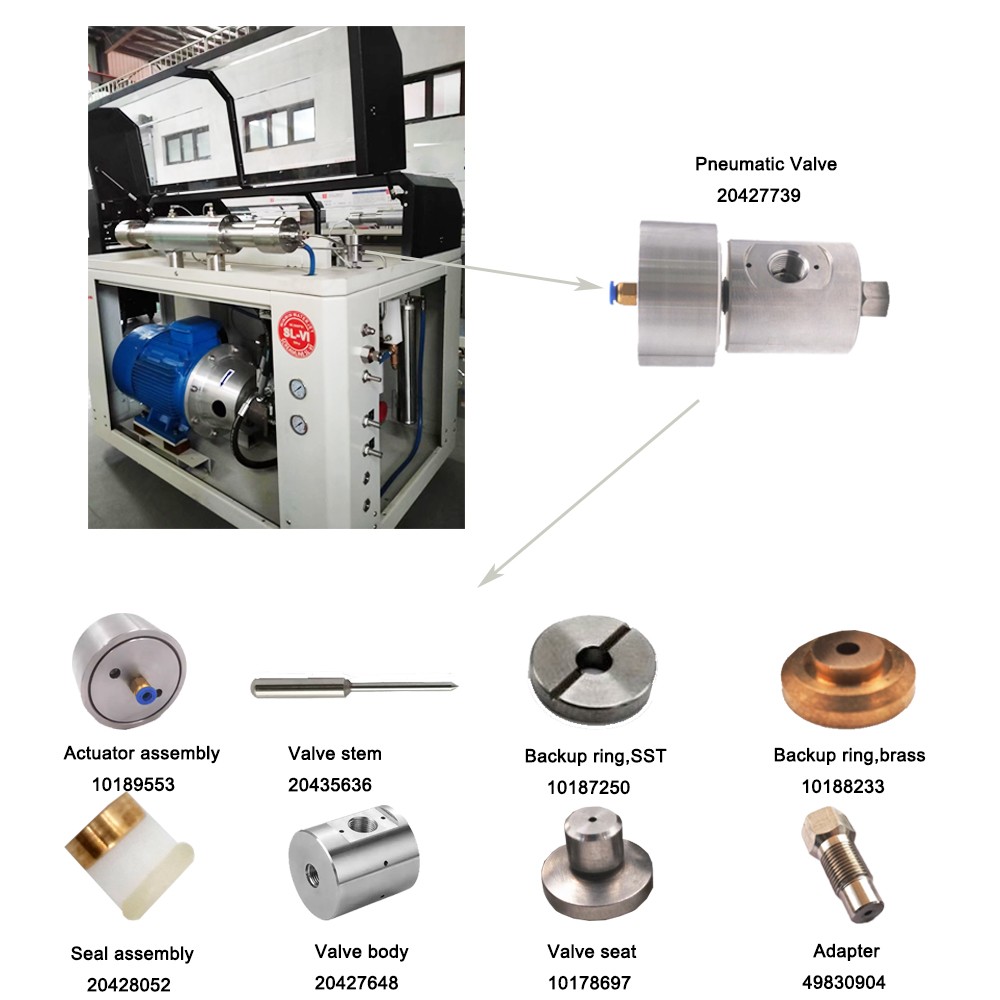

In addition, the static torque of the water jet spare part motor is greater than the pneumatic torque; The rated torque is greater than the continuous working torque of the motor, and a certain margin shall be reserved. As a servo motor of ultra-high pressure water jet cutter, its step angle matches with the transmission system to obtain the required pulse equivalent. As for the high-pressure system of high pressure water jet cutting machine with water jet spare part , reciprocating intensifier is often used. Its pressure can be as high as 400MPa and its stable working range is not less than 350Mpa, which can meet almost all application requirements.

The above are the advantages of gantry and cantilever water jet. The model configuration can be customized according to the actual situation. The main application fields of water jet are: processing of building materials such as ceramics and stone; Glass products processing, such as architectural decoration and craft glass; Metal plate cutting and blanking in machinery industry; Art pattern cutting and so on.

As a new environmental protection, high pressure water jet has a broader application prospect What is high pressure water cutting machine? It is a set of water jet cutting system and water jet spare part composed of high pressure system, softened water treatment system, safety protection system, electrical control system. It is applicable to a variety of materials (such as glass, marble, leather, plastic, steel plate, internal punching and trimming of automobile interior trim), and can carry out three-dimensional cutting processing for complex workpieces with free-form surface.

It has the advantages of flat incision and good consistency. With the continuous development of high pressure water jet technology, as a new environmental protection and safe cutting equipment,high pressure water jet will have a broader application prospect. High pressure water jet cutting with good water jet spare parts has a faster starting speed, and can be used for various plastics, synthetic building boards, foam materials, etc.

wwaterjet

wwaterjet