Application of water jet

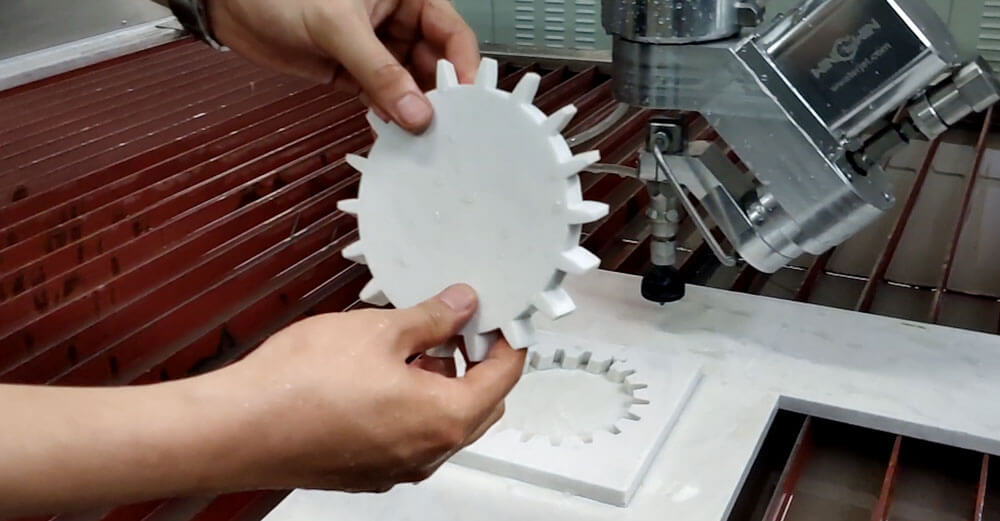

For ceramic and stone

If it is necessary to cut the curve, first make the template that meets the size requirements, and then implement it mainly by manual grinding after preliminary cutting.Water jet is the main processing machine in ceramic and stone industry, which is widely used. Its outstanding feature is all curve cutting covering ceramic stone. Common examples include large-scale ceramic murals, hall floor patches, ceramic screens, special-shaped platforms on cupboards, stone furniture, etc.

Compared with traditional cutting methods such as laser, plasma and wire cutting, water jet cutting technology with water jet spare parts unique and obvious advantages. The outstanding advantages of water cutting technology are as follows:

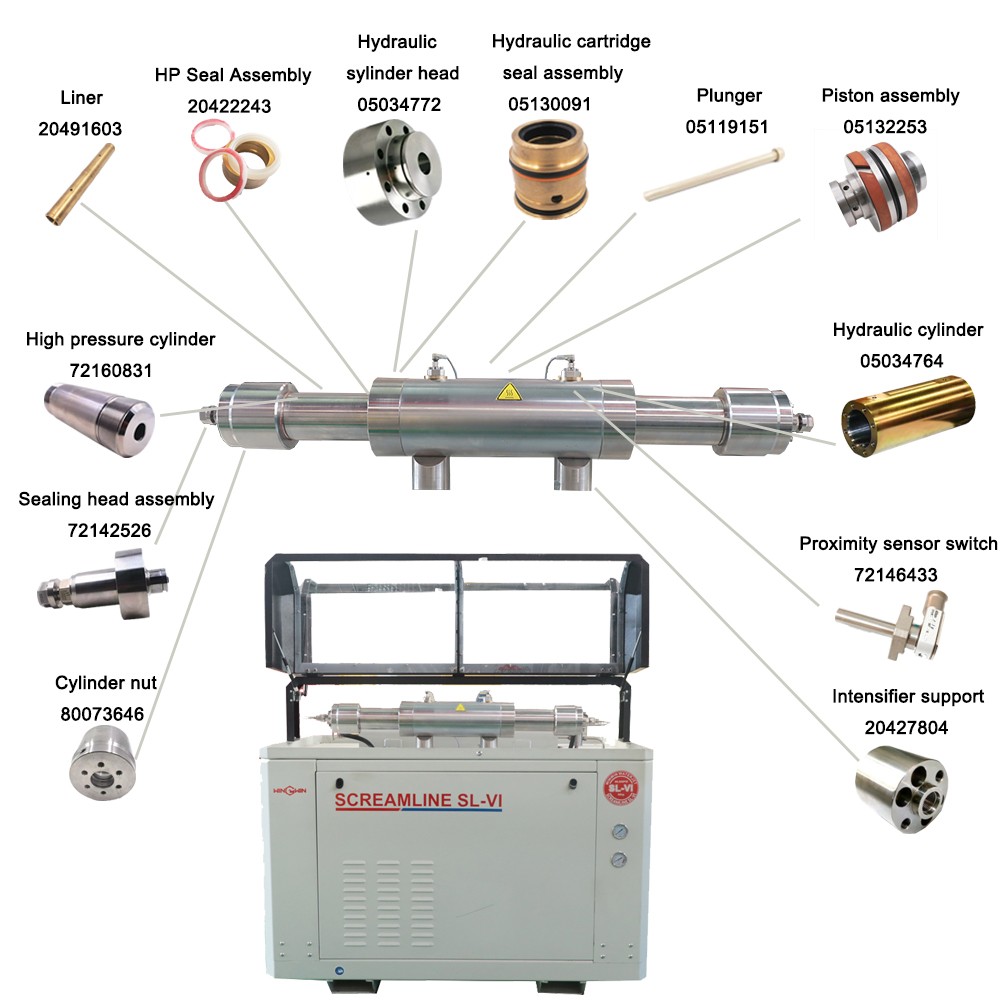

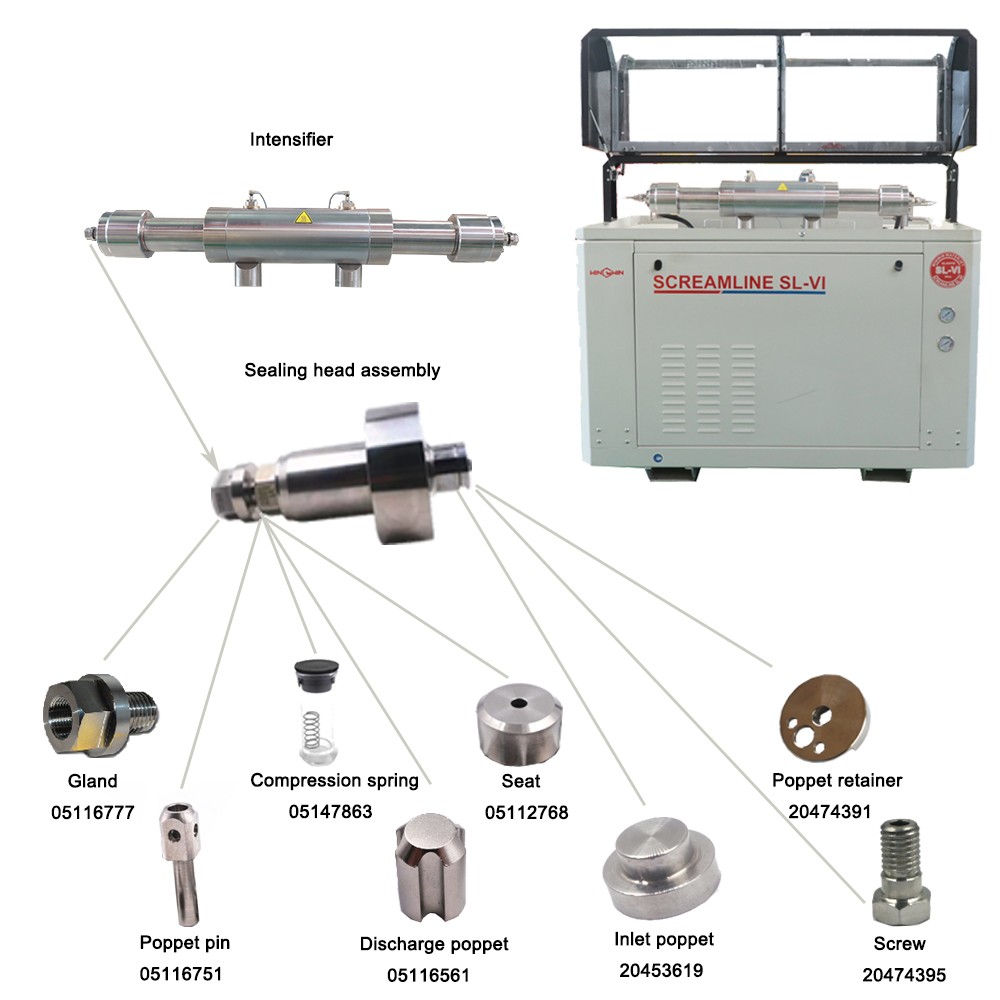

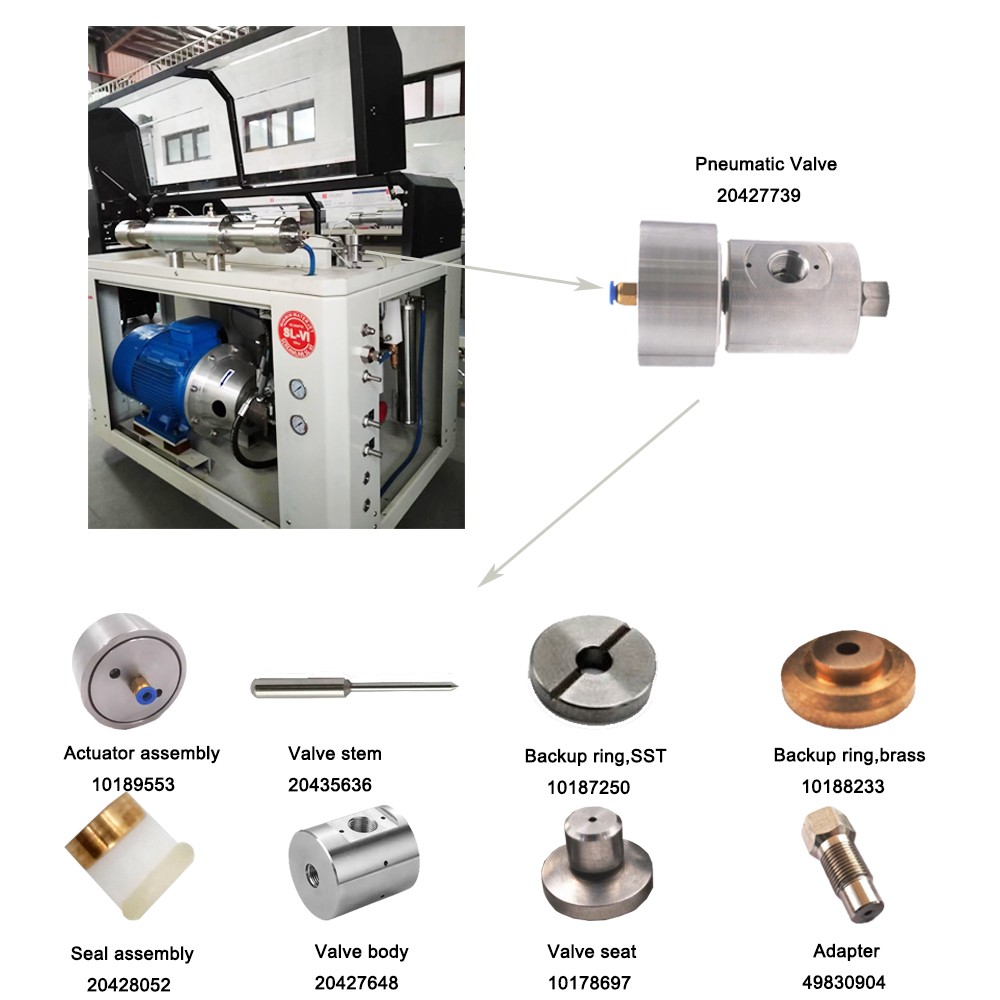

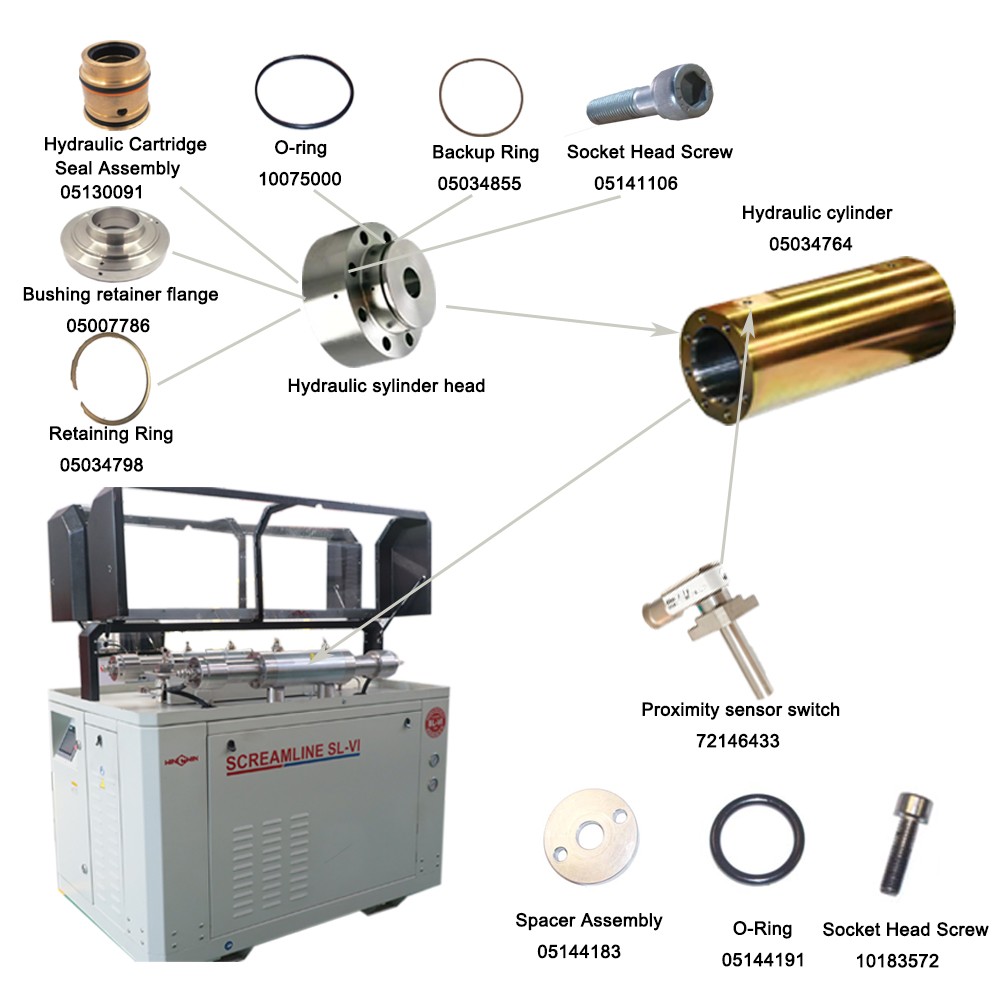

The water jet machining with water jet spare parts itself has no heat, the machining force is small, and there is no heat affected area on the machining surface. The fabric structure of the material remains unchanged in natural cutting. There is also little heat and machine stress and deformation. The cutting clearance and cutting slope are very small. No secondary processing, no cracks, no hair, no debris, so the cutting quality is good by using high quality water je spare parts for your waterjet intensifier pump.Water jet cutting is a cold working method. Water cutting does not wear and has a small radius. It can process small arcs with sharp edge contours. Applicable to metal (such as ordinary steel plate, stainless steel, copper, titanium, aluminum alloy, etc.) or non-metal (such as stone, ceramics, glass, rubber, paper and composite materials). Third,it can reduce costs when you use high quality water jet spare parts. Because good water jet spare parts can reduce the downtime of your waterjet cutting machine.

The transverse and longitudinal forces generated by the water jet cutting system are very small, which will not produce thermal effects, deformation or micro cracks. It does not need secondary processing, and can be drilled or cut, so as to reduce the cutting time and manufacturing cost with good water je spare parts.

For those materials processed by water cutting machine, the cut is very smooth and there are few rough burrs. In addition, there will be no thermal effect, so there will be no unnecessary deformation or small slit in the middle of the material. Generally speaking, the water jet cutting machine has many advantages, and the main advantages are concentrated in three aspects. At the same time, the cutting speed is faster because it does not need to constantly change the cutting tools according to different cutting materials.

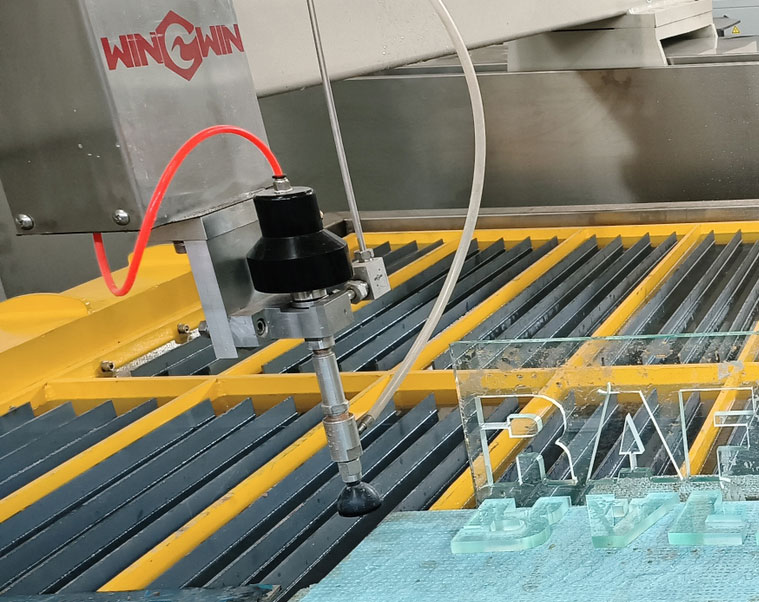

For glass

Water jet cutting equipment is commonly used in glass cutting industry, and glass is more and more used in various industries. Glass cutting of household appliances (gas stove, range hood, disinfection cabinet, TV, refrigerator, etc.); Lamp; Craft glass; Bathroom products (shower screen, etc.); The addition of water jet cutting technology provides a fast and convenient solution for the diversification of glass products with water jet spare parts.

For the glass industry, water jet cutting equipment can handle any geometry you want. Whether drilling or modeling, the water jet can cut skillfully with water jet spare part. Its main features are: accurate, durable, diverse, incision does not contact porcelain, incision wear-resistant, beautiful, incision frosting; There is no thermal effect, scratch, safety and rework during cutting. The glass can be cut arbitrarily, the clamping is intuitive and the operation is convenient. The cutting seam is only 1mm, the cutting surface is smooth, there is no broken edge, the cutting range is wide, and the glass thickness can reach 100mm.

The glass conveying line can be operated simply by remote control, saving time and labor cost. The waterjet cutting control system adopts Italian ECS system, which has high cutting accuracy, supports multiple languages and is easy to learn. With WIN-WIN water jet spare part, you can cutting perfect glass edge. Specially customized nylon rollers are used inside the water tank to carry the glass and prevent the glass from being damaged. The truss carries 3-axis double cutter heads, which saves time and improves efficiency. When the glass passes through the conveying line, the feeding suction cup will suck up the glass and put it on the water tank for cutting and punching. The glass after the operation will be transferred from the feeding suction cup. The loading and unloading suction cups perfectly control the time node, ensure the smooth operation of the production line, save time and labor cost, and protect the glass from damage.

Water jet cutting machine, commonly known as water arrow, uses ultra-high pressure technology and high quality water jet spare part to pressurize ordinary tap water to a certain pressure, and then let it form a high-speed jet through the jet nozzle to cut all kinds of materials.When selecting the cutting materials , we should choose the reliable water jet cutting machine and water jet spare parts.

wwaterjet

wwaterjet