Selection of water jet cutter

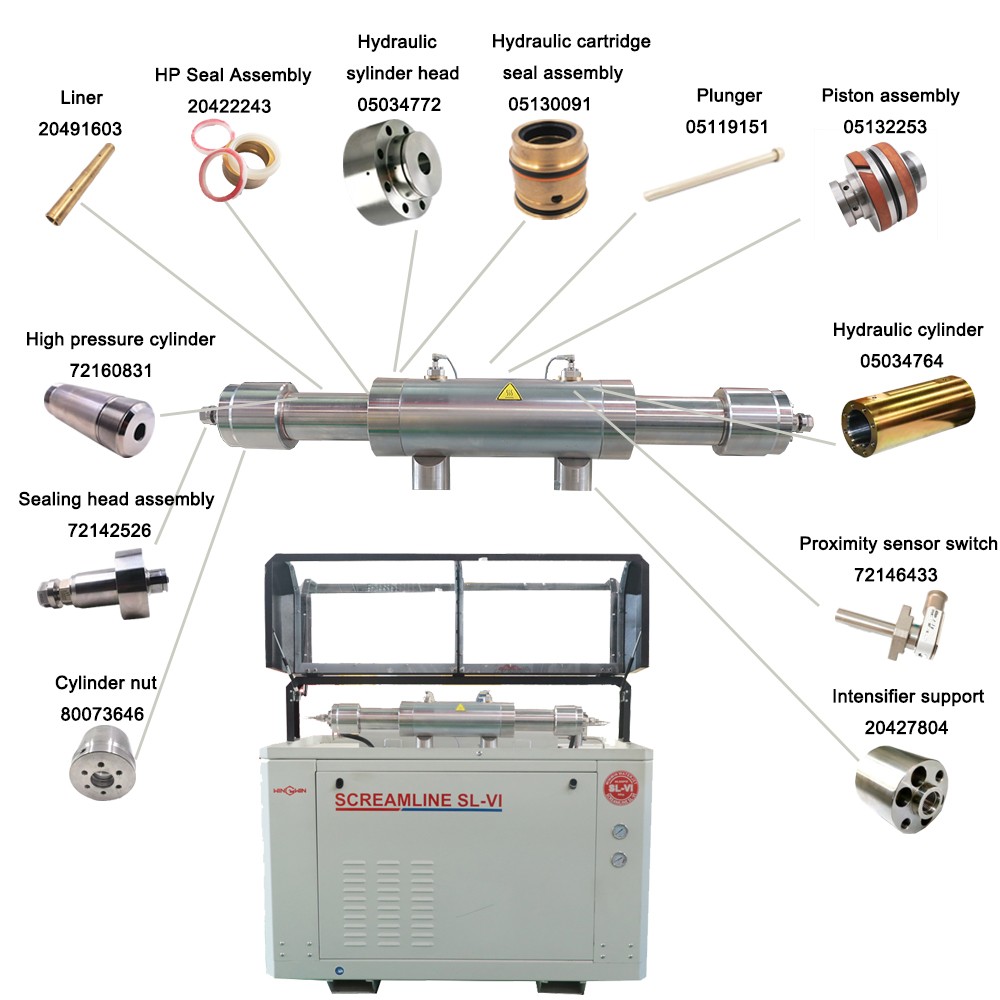

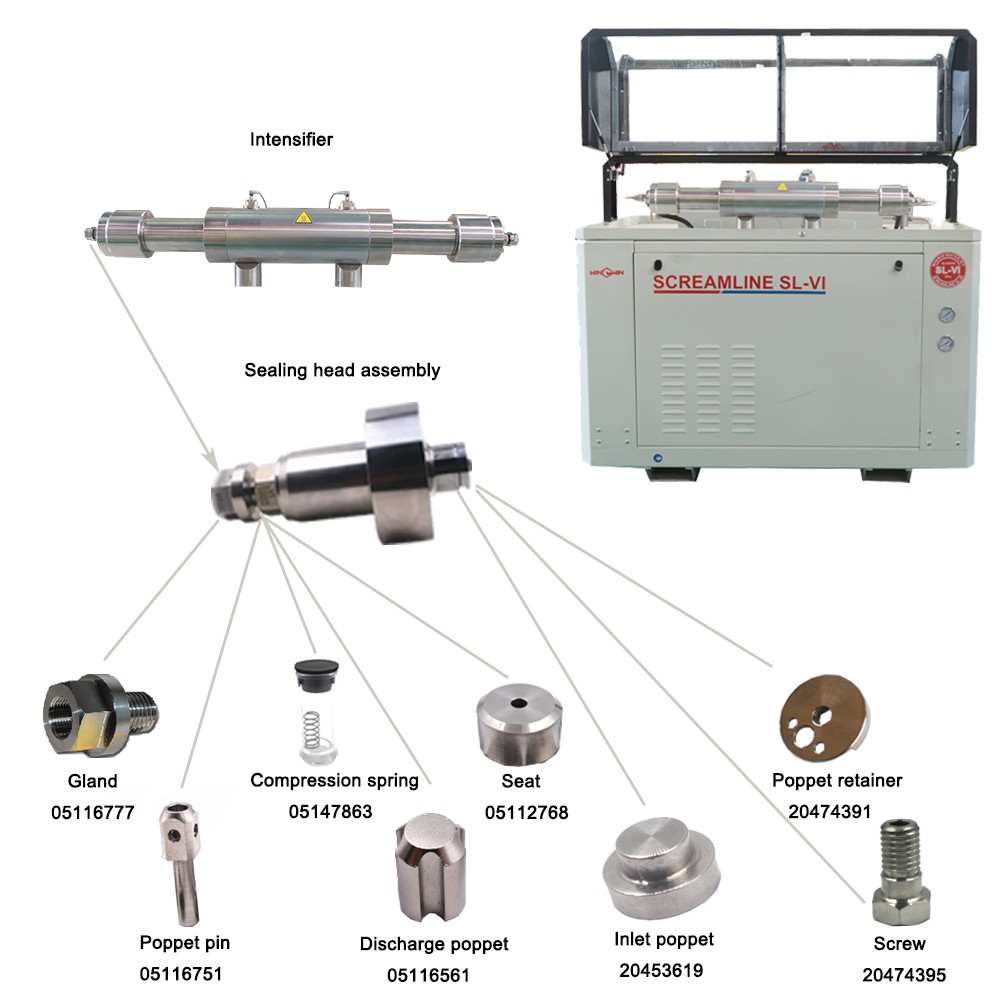

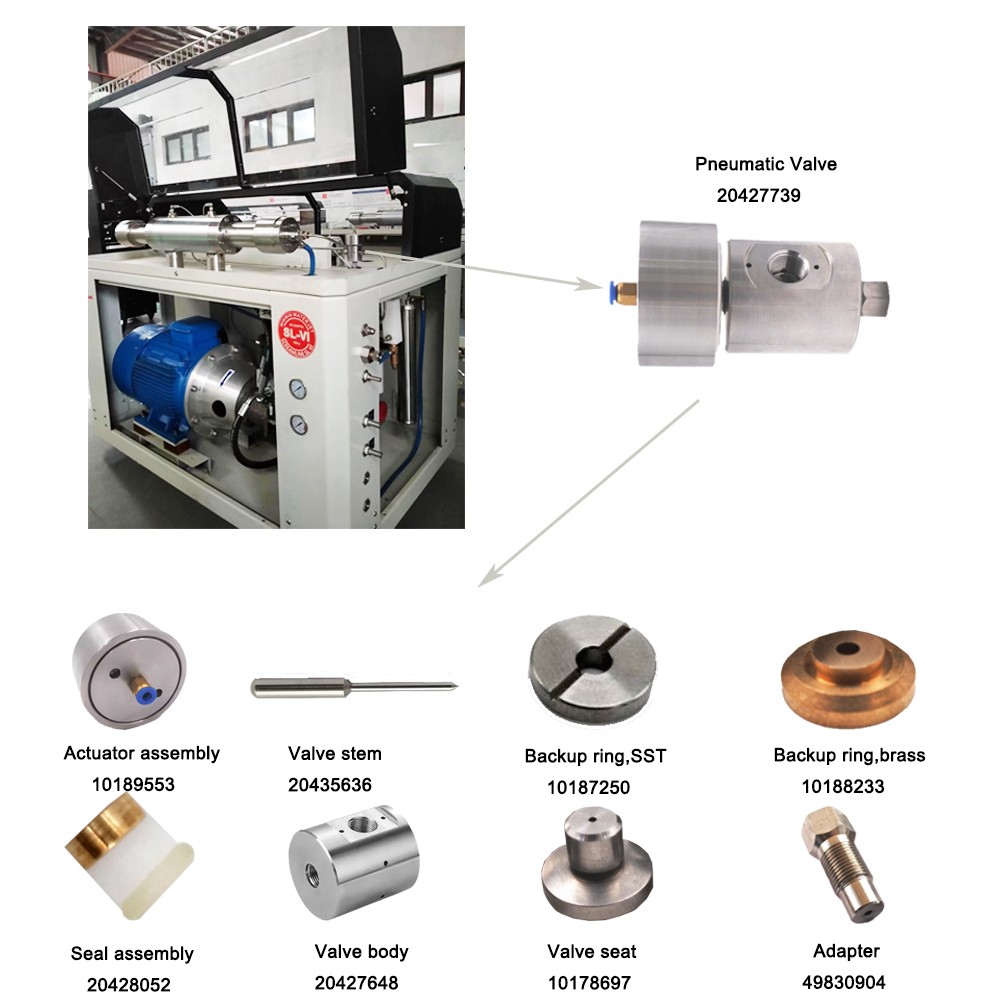

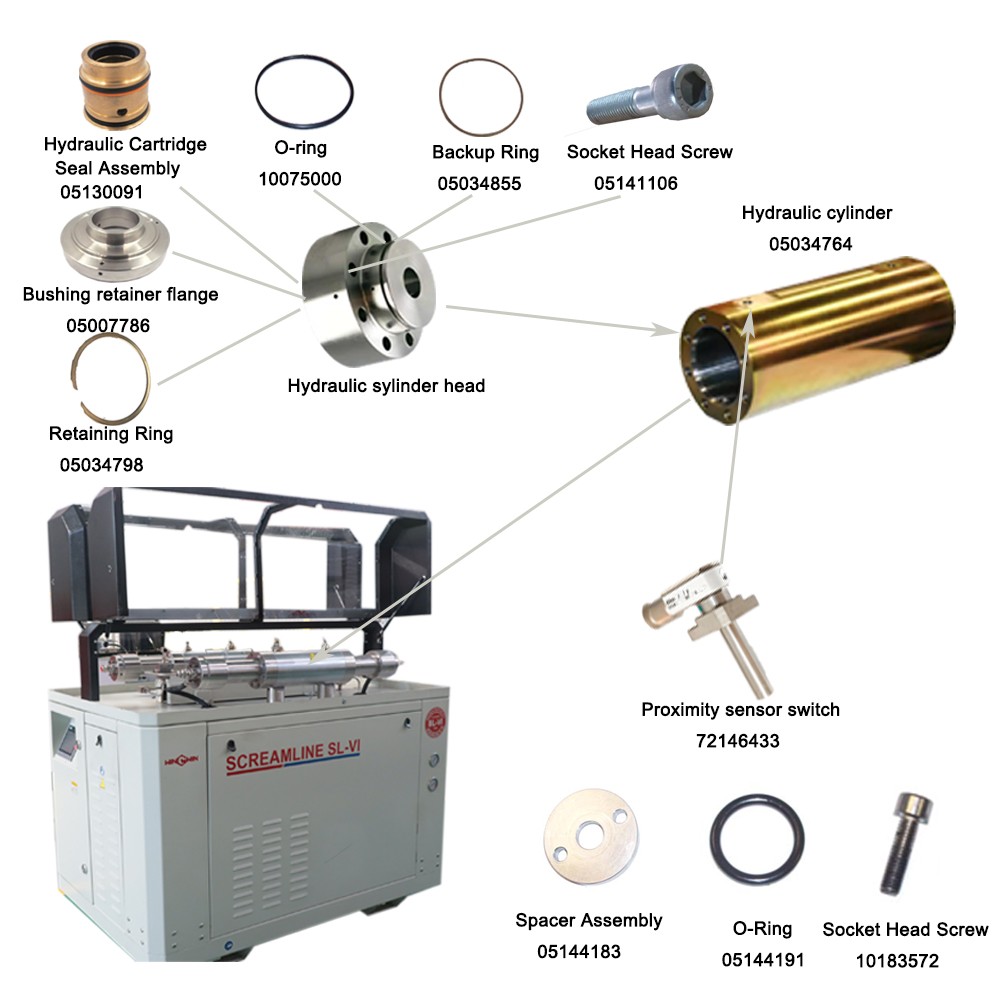

Just like shopping in shopping malls, customers must measure their needs according to the actual situation and buy water knives. The existence of multiple machines has produced many different price levels. Carefully check your production needs and water jet spare part brands for your waterjet intensifier puump here, and pay attention to matching the machine with it, so as to reduce unnecessary expenses.

The two most common water jet cutting machines on the market are gantry and cantilever cutting platforms. The gantry cutting platform is an integrated structure. Its main feature is that the double motor drives the Y beam, and the X beam has two fulcrums. The advantage of the structure is that it makes the cutting platform more stable, accurate and safe. In fact, it is applicable to the occasions where the material and size of cutting materials are relatively fixed, the loading and unloading is relatively convenient, or the loading and unloading method is relatively fixed.

The main feature of the cantilever water jet cutting platform is that the cutting arm track is structurally separated from one side of the cutting platform. There is only one motor drive on the Y-axis and one support point on the x-axis. The utility model has the advantages of convenient and fast blanking and relatively low cost. Due to the separation of the motion mechanism and the cutting platform, there will be no interference and influence on each other.

The space for loading and unloading materials is relatively large. In fact, it is suitable for the use environment with irregular materials and sizes and irregular loading and unloading methods by using high quality water jet spare parts. In fact, it is also very convenient to change to a larger cutting platform in the future. It is worth noting that we only need to re purchase or make a new cutting platform, which also greatly saves the cost using high quality water jet spare parts

In fact, the material you want to cut with a water jet and the thickness of the material, because the influence of water jet equipment and water jet spare parts on the accuracy of the workpiece is also different. To cut a workpiece with a thickness of more than 0.5 inch, each cutting head shall have at least 50 horsepower. Smaller cutting heads cost more per inch. However, it is sometimes more effective to use two small cutting heads than one large cutting head. By checking the cycle time at each configuration and the cost of each workpiece, you can know whether one or two water jet spare part cutting heads are more effective.

Raw material board, determine the size of the machine for a particularly large board size, which is more expensive. In fact, the cheaper method is to separate the larger plates before putting them into the water cutting equipment, or hang the larger plates outside the edge of the collector.

Another question worth discussing is whether precision is needed to make workpieces? Just like the plate size, the buyer should also consider the main work to be done, not the most accurate work. It is worth noting that if the root mean square value is 100 to 250, can the sandblasted surface finish be used as "original cutting"? If you don't have to do a second operation to get a smoother surface (root mean square value higher than 100), the cost per part you spend on the water jet cutting machine and water jet spare parts will be quite lower. It is worth noting that cutting with water jet equipment can save a lot of cost compared with hard materials (such as quenched steel, titanium, nickel alloy and ceramics).

Advantages of water jet cutting

1. Advantages of water jet cutting as a cold cutting process In this case, when water jet cutting, it needs the high-energy jet of non heat source to process the materials. Compared with the heat source energy, it can not only better control, but also effectively avoid the deformation of processed materials caused by too high heat source, which helps to ensure the cutting quality with good water jet spare parts.

2. Cutting metal by water can reduce costs This is a very excellent technology. When cutting metal, the force generated by both horizontal and vertical is very small, which can reduce the setting time and the cost of using clamping tools. Moreover, due to the fine incision of water jet cutting and no burr of metal, it not only shortens the manufacturing time of workpiece, but also reduces the waste of materials, thus directly reducing the manufacturing cost if you use WIN-WIN water jet spare parts.

3. Water jet cutting metal can increase production capacity Since water jet cutting has no restriction on the cutting direction, it can complete various cutting shapes, and can be flexibly adjusted according to the material,processing requirements of the workpiece, so as to improve the production efficiency.In addition, when water jet cutting processing metal, it does not need cumbersome process, and the workpiece can be completed at one time without secondary processing, which can provide great convenience for users. Due the feature of waterjet cutting technology and water jet spare parts,it is the best to choose waterjet cutting machine cut metal.

wwaterjet

wwaterjet