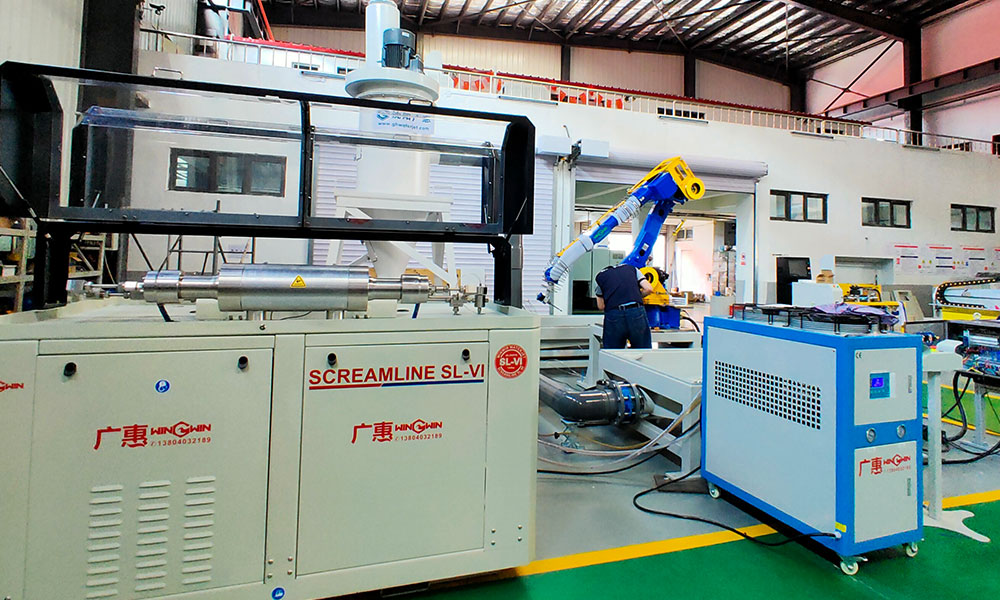

Robot waterjet cutting solution

The robot water jet cutting system is characterized by fully enclosed and house structure. When the robot cuts the workpiece, it cuts in a closed house. There are windows to observe the internal cutting. It can be said that such a structure has almost zero risk, and the safety can be better guaranteed. The front and rear are equipped with lifting roller shutter doors. When the operator presses the close roller shutter door button, the roller shutter door will close and trigger the starting device of the cutting system, and the system will cut automatically. When the cutting is completed, the roller shutter door will open automatically and wait for the next cycle. The operation is very convenient. The basic process is to press the start button for cutting, change the cutting material after cutting, and then press the start button again for cutting. In this cycle, press the emergency stop button in case of emergency.

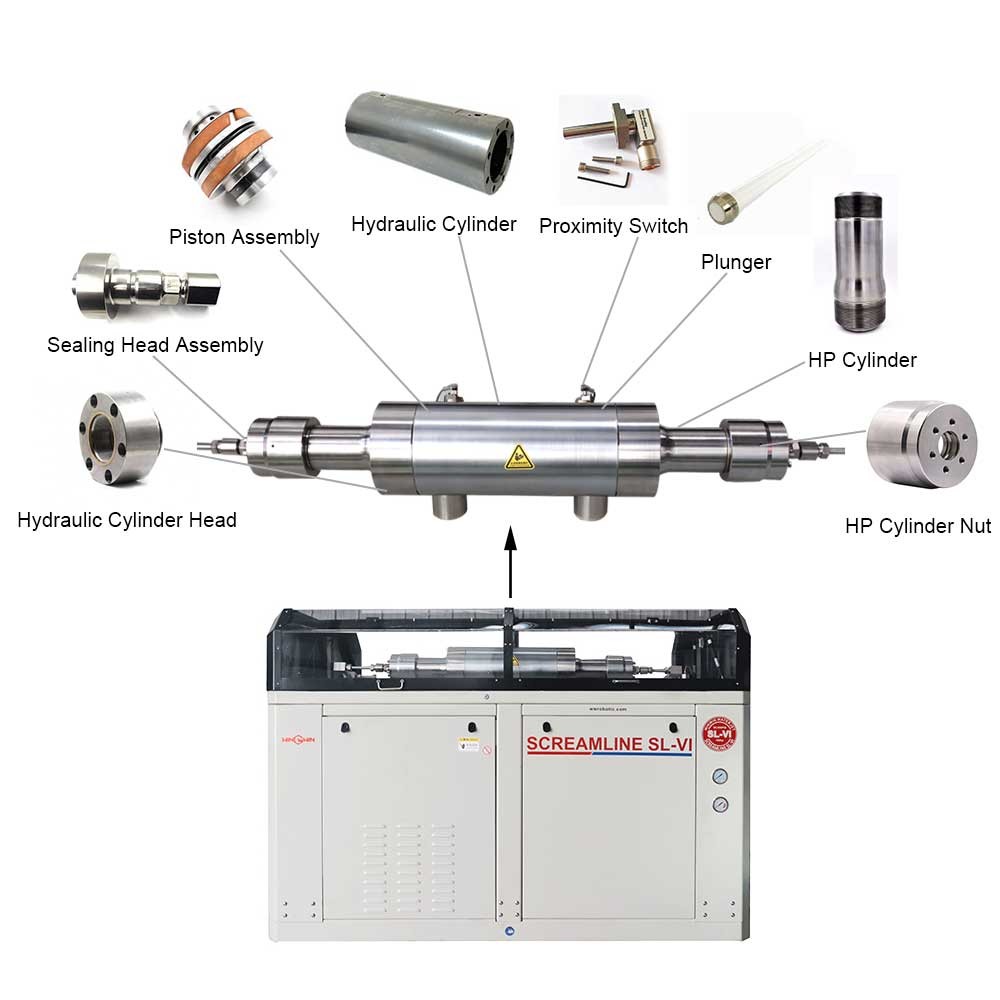

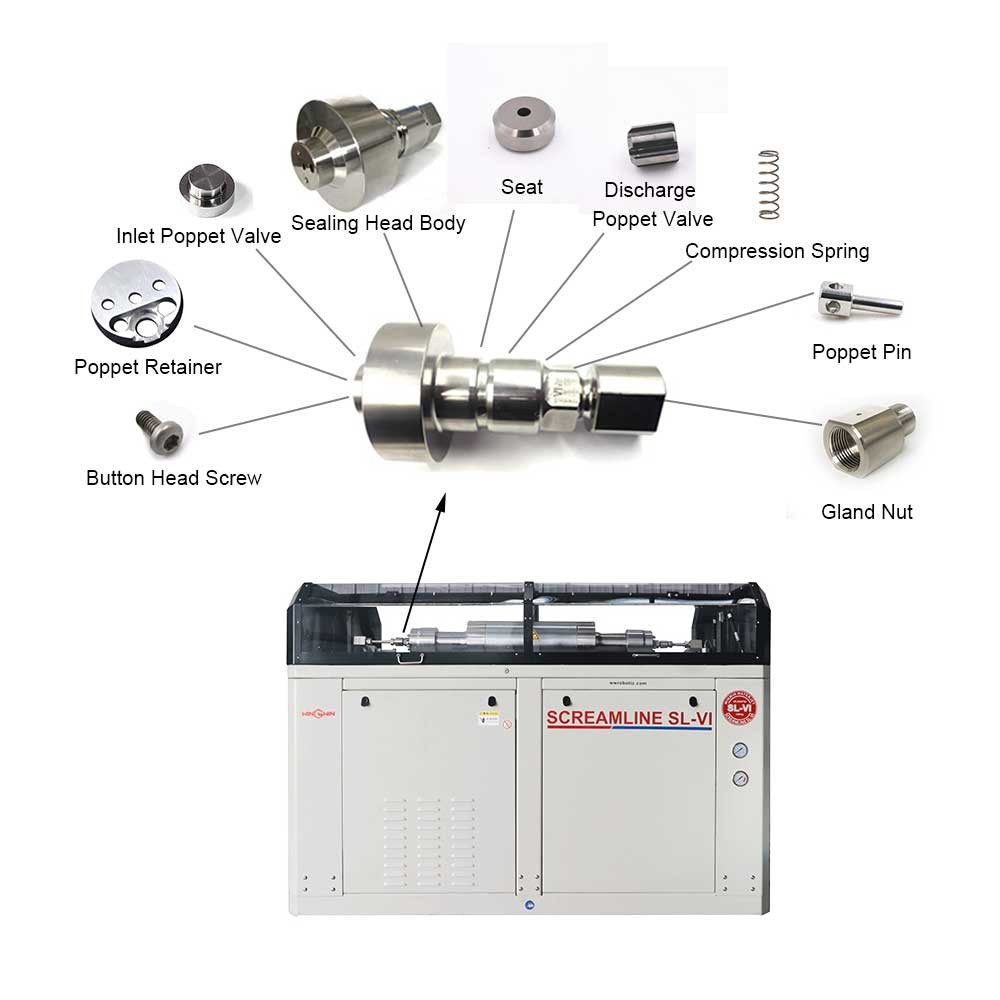

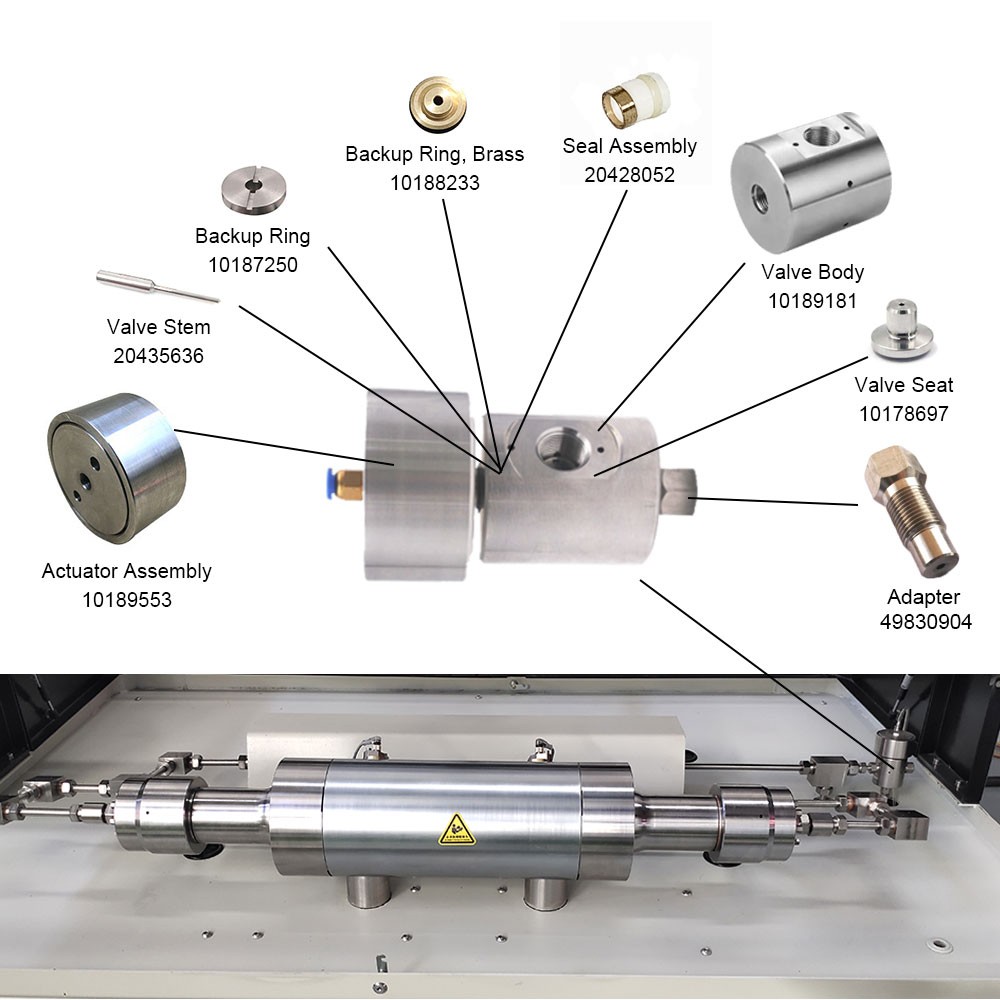

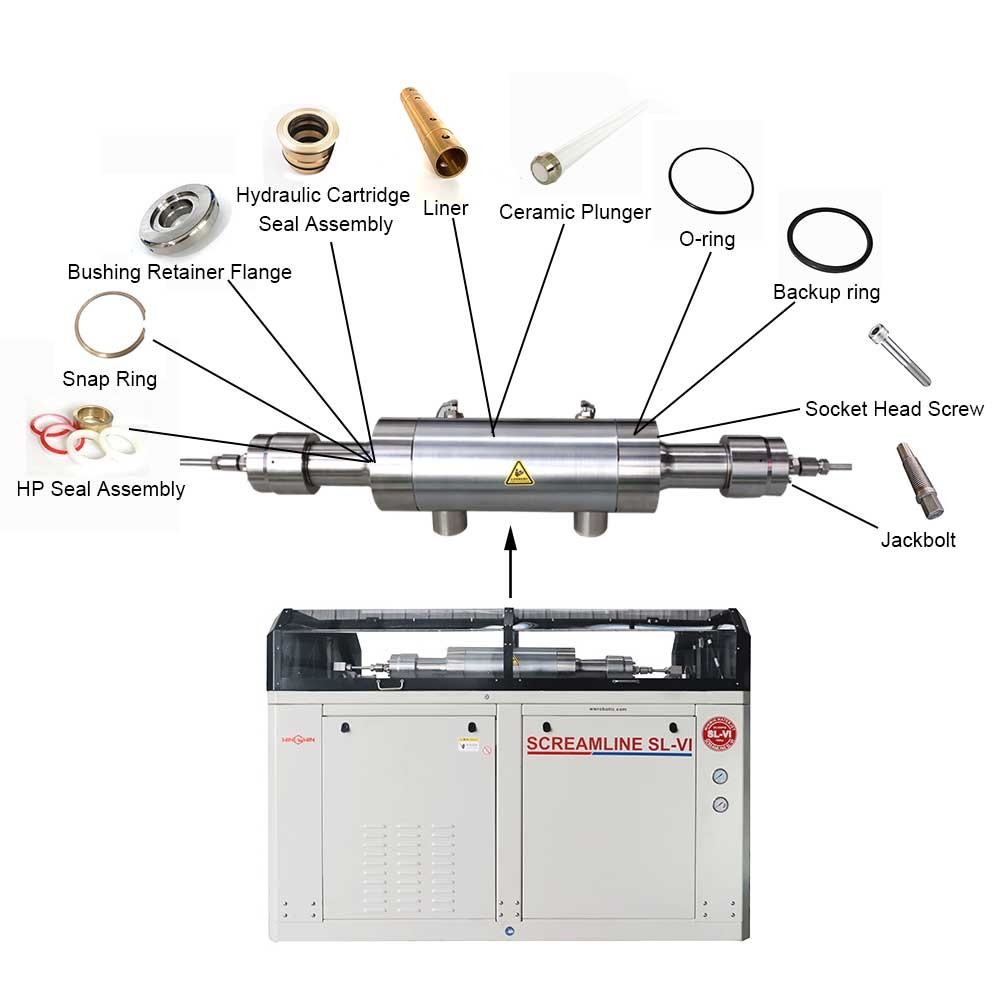

For the floor type structure, this type is upgraded to ceiling type, using single,dual or triple robot arms. The replaceable robots are: ABB 2600, FANUC m20ia, YASKAWA MH 20 etc. Compared with the floor type structure, the ceiling type has a larger effective cutting area, which is also the key for many companies to choose the ceiling type robot. Each robot arm is responsible for each corresponding part of the same cutting material, This mode will further improve the production efficiency by using waterjet spare parts. The production efficiency of the ceiling robot water cutting equipment is 1.5 times that of the pedestal type . You can use different types of intensifier pump and related waterjet spare parts which can drive different numbers of robot arm.

Pedestal type robot arm waterjet cutting system always use ABB IRB 4600 robot. It has a larger cutting range. The replaceable robots are: FANUC m70ic, YASKAWA MH 50 etc.Various auxiliary designs and the design of center of gravity point enable the robot to have greater inclination and greater arm spread. At present, it is more pedestal type installation, because the cutting range of abb4600 robot is large enough, and economical installation method. It has the advantages of simple operation, short construction period and convenient installation. More importantly, it has high cost performance and is the first choice of customers with high quality of watejet spare parts.

ABB IRB 4600 robot arm can be described as slim. Using the latest alloy body can increase the strength and reduce the volume. The compact design at the rotating joint has the advantage of reducing the weight and is more conducive to the water jet cutting speed of the robot. On the other hand, the waterjet spare part high-pressure coil equipped with the robot water jet cutting and waterjet spare parts is relatively short and saves the cost.

The usage of robot waterjet solution

In the aerospace industry, it is used to cut boron fiber, carbon fiber and other composite materials. There is no delamination and heat accumulation during cutting, and the cutting edge quality of the workpiece is high.

In the food industry, it is used to cut crisp food, vegetables and meat, which can reduce the damage of cell tissue and increase the storage period.

In the paper industry, it is used for slitting kraft paper, corrugated box board, etc., without dust pollution, and the cutting speed is as high as 1828m / min.

Also in the electronic industry, it is used for contour cutting of printed circuit board.It is also used to cut multi-layer cloth in the textile industry, which can improve the cutting efficiency and reduce the damage of edges and ends by using high quality of waterjet spare parts.

In short, the application scope of ultra-high pressure water jet cutting technology is expanding day by day, and the potential is huge. It is worth noting that with the continuous reduction of equipment cost, the universality of its application will be further improved by using high quality of waterjet spare parts.

Robot water jet cutting machine is an advanced processing technology and unique equipment. The stone mosaic cut by it has great randomness and is not limited by the processing difficulty. In fact, regardless of the processing efficiency, it is worth our attention that the processing quality and decoration effect are the best equipment for processing the mosaic with high difficulty, high artistic sense and modeling sense by using high quality of waterjet spare parts.

Stone mosaic is a difficult technology in stone processing technology. Its requirements include the need for precision, accuracy, integration and the effect of the unity of nature and man. In fact, it mainly depends on machinery and equipment, as well as the ability of design and the ability of technicians to understand and recognize drawings.

wwaterjet

wwaterjet