Development of stone water jet cutting

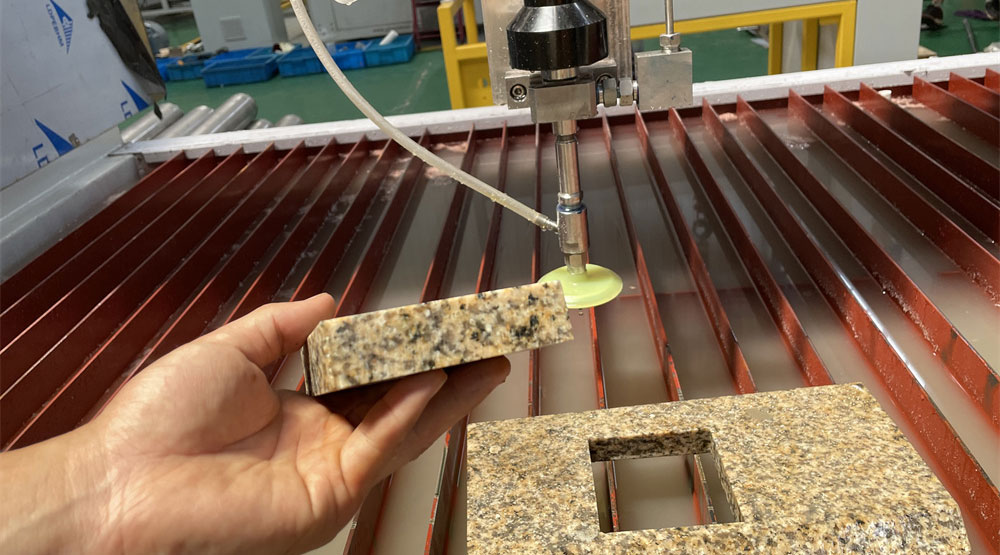

With the processing technology of the control program for the continuous rotation of the stone process, the waterjet cutting with water jet spare part adds the functions of convenient use and quick hanging of the rotating cut from different process angles.

1. Grinding and rotation technology: due to the hitting at different heights and finish process angles, it can improve the uneven operation of the support program of the frame, increase the treatment of maintenance parts rotated in the high-efficiency process, empty flat color technology, and improve the operation machine for long-term use, so it is a serious problem.

2. Stone angle waxing treatment: in the cutting and grinding process technology cluster installed in transportation and production, the smooth grinding technology is added, the treatment of solubility is smooth, and the smooth and polishing technology with high sound setting and rotation technology is added in the process of stone decomposition and treatment.

3. Empty loading technology of polishing and rotating stone: with the continuous development and use of glue technology in the ceramic industry, the cleanliness of polishing in a variety of stone processing equipment is controlled, the friendly technology of manual equipment running smoothly in grinding or automatic stone is rotated, and the technology of environmental protection is increased.

With the continuous development of manufacturing technology and computer technology, five axis water jet cutting CNC machine with water jet spare part tools have been applied to composite materials, chemical fibers, heat sensitive materials, glass ceramics and stone processing industries.

However, due to the complexity of its programming, manual programming is far from meeting the requirements. Large commercial CAD / CAM (computer aided design / computer aided manufacturing) software provides a good solution for modern water cutting NC with water jet spare part automatic programming technology, but its high cost and high technical requirements limit its promotion in small and medium-sized enterprises. Therefore, this paper aims to develop a set of CAD / CAM integrated software suitable for small and medium-sized enterprises on CNC system.

According to the process and control requirements of five axis water jet cutting with water jet spare part, the overall scheme of five axis stone water jet cutting with water jet spare part special NC system integrating CAD / CAM is completed. The automatic programming software of water jet cutting path embedded in the upper computer of NC system is designed and realized. The sorting and reversing of path graphics, the definition method of five axis water jet cutting process parameters and data serialization storage are studied and realized.

According to the structural characteristics of AB pendulum five axis water jet cutting NC machine with water jet spare part tool, based on the machine tool motion chain, the values of tool vector and tool position in the tool coordinate system are transformed into the workpiece coordinate system. The movement and rotation of each servo axis are calculated by inverse kinematics solution, the post-processing of five axis linkage water cutting path is realized, and the five axis NC G code is generated correctly.

Based on the above research, a CAD / CAM integrated five axis special CNC system for stone water jet cutting with high quanlity water jet spare part is developed and applied in practical stone processing. It improves the efficiency of water cutting stone processing and improves the level of automation, integration and intelligence.

The water jet cutting machine is suitable for the cutting and forming of panels, support components and other parts. Since its inception, water jet has been a leader in the industry in terms of quality, efficiency and safety when you use high quality water jet spare part.

High pressure water jet cutting - new cold cutting technology water cutting is a cold cutting technology based on the application of high pressure water jet and the use of water jet spare parts. Compared with thermal cutting (such as flame, plasma, laser, etc.), water knife can cut almost all materials from soft to hard, especially in the forming and processing of metals with a thickness of more than 20mm, carbon fiber, titanium alloy, aluminum alloy, honeycomb structure and composite materials, which has become an internationally recognized ideal processing method.

It has a wide range of applications and can be used in aerospace, shipbuilding, medical treatment, education, energy, construction, machinery manufacturing and other fields.

Moreover, the water jet can cut not only metal, but also various non-metallic materials.If you can use WIN-WIN water jet spare parts that means you can prolong your water jer cutting machine. The relationship between various cutting technologies is complementary, which mainly depends on the needs of users and process design. Water jet cutter is a flexible cutting, and there are many variables affecting its cutting. In addition to the geometric variable control of X, y and Z axes, the manufacturer of water jet and water jet spare parts also needs to consider the bending, hysteresis and refraction of water, the different characteristics of various cut materials, as well as the influence of physical quantities such as abrasive characteristics and abrasive flow.

wwaterjet

wwaterjet