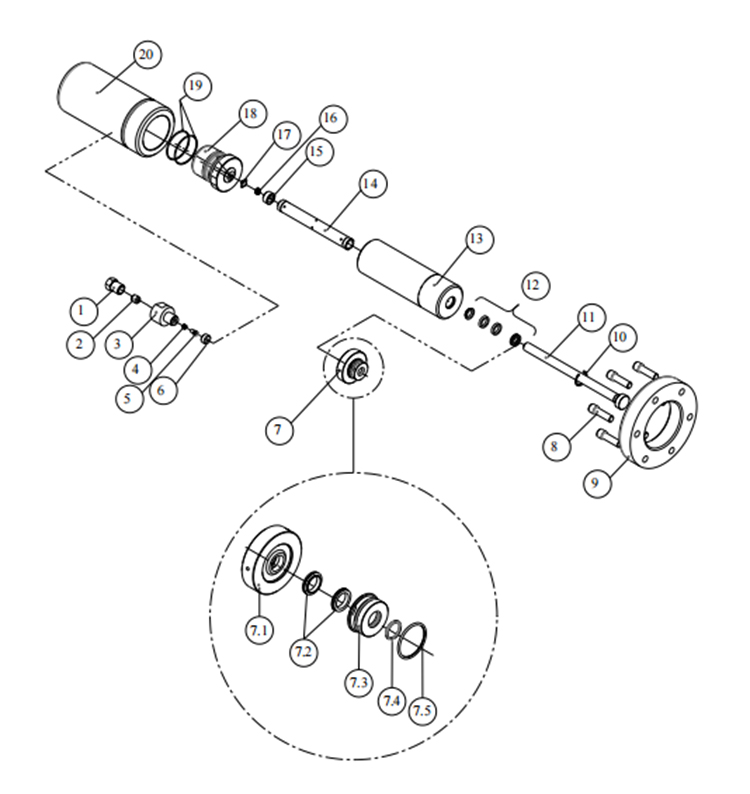

Techni Waterjet SP1042 Wiper seal 17.5mm

The TECHNI Waterjet SP1042 Wiper Seal 17.5mm is an essential component used in TECHNI waterjet cutting systems. Wiper seals, also known as scraper seals, are designed to prevent contaminants from entering the hydraulic system by wiping off dirt, dust, and moisture from the piston rods as they retract into the cylinder.

Key Aspects of the TECHNI Waterjet SP1042 Wiper Seal 17.5mm

Material:

Polyurethane (PU): Commonly used for wiper seals due to its excellent abrasion resistance, durability, and ability to maintain a tight seal under high-pressure conditions.

Other Materials: Wiper seals can also be made from materials like Nitrile (Buna-N), Viton (FKM), or other elastomers depending on specific application requirements and operating conditions.

Dimensions:

Diameter: The 17.5mm specification refers to the diameter of the seal, which must match the dimensions of the piston rod or cylinder it is designed to protect.

Profile: The profile of the wiper seal is designed to effectively remove contaminants while maintaining a tight seal around the piston rod.

Function:

Contaminant Exclusion: The primary function of the wiper seal is to prevent contaminants such as dirt, dust, and moisture from entering the hydraulic system.

Seal Protection: Protects other seals within the hydraulic system from premature wear and damage caused by contaminants.

System Integrity: Helps maintain the overall integrity and performance of the hydraulic system by ensuring clean operation.

Maintenance Tips for Wiper Seals

Regular Inspection:

Periodically inspect the wiper seal for signs of wear, cracking, or damage. Regular inspections help identify issues early and prevent contaminants from entering the system.

Proper Installation:

Ensure the wiper seal is installed correctly, following the manufacturer’s guidelines. Incorrect installation can lead to ineffective sealing and allow contaminants to enter the system.

Clean Environment:

Maintain a clean working environment around the hydraulic system to reduce the amount of contaminants that the wiper seal needs to manage.

Seal Lubrication:

Use compatible lubricants if recommended by the manufacturer. Lubrication can help reduce friction and wear on the wiper seal, extending its lifespan.

Troubleshooting Common Issues

Contaminant Ingress:

If contaminants are entering the system, inspect the wiper seal for damage or improper installation. Ensure the seal is correctly positioned and in good condition.

Seal Wear:

Regular wear and tear can degrade the wiper seal over time. Replace the seal as needed to maintain the integrity and performance of the hydraulic system.

Hydraulic Fluid Leaks:

If hydraulic fluid leaks are observed, check the wiper seal and other seals in the system for damage or wear. Ensure all seals are functioning correctly to prevent leaks.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet