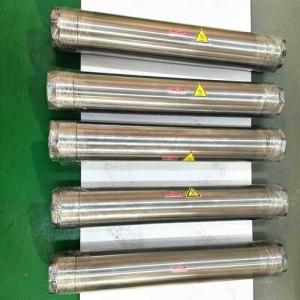

REPLACEMENT Robotic Waterjet parts Coil 103263

Robotic Waterjet parts Coil 103263 Description

Item number: 303263

Details: Robotic Waterjet parts Coil 303263 used on M98-2400/10 Axis 4,5,6 robot waterjet cutting system

ABBIRB2400 WATERJET HIGH PRESSURE COIL TUBE

| 24602490 | Coil Axis 2 |

| 303743 | Coil Axis 1 |

| 303748 | Coil Axis 3 |

| 303747 | Coil Axis 1-2 |

| 304491 | Coil Axis 4,5,6 |

| PEL01 | Coil Axis |

| PEL02 | Coil Axis |

| 303721 | Coil Axis 1 |

| 20427978 | Coil Axis Special |

| 49830052 | Coil Axis |

ABBIRB2400 NEW WATERJET parts Coil 103263

| 103260 | Coil Axis 2 |

| 103261 | Coil Axis 3 |

| 103262 | Coil Axis 4,5,6 top |

| 103263 | Coil Axis 4,5,6 Down |

| 103880 | Coil Axis 4,5,6 up and down |

| 104611 | Coil Axis 3 |

| 105287 | Coil Axis 1 |

What are the main parts of robots in robot waterjet cutting?

Robot waterjet cutting systems involve the use of industrial robots that are equipped with waterjet cutting heads. These robots are used to precisely control the cutting process. The main accessories and components associated with the robots in robot waterjet cutting systems include:

Robot Arm:

The robot arm, which is the core component of the robot, is responsible for positioning the waterjet cutting head with high precision. The arm's reach and payload capacity are important considerations for its suitability in specific applications.

Waterjet Cutting Head:

The cutting head is equipped with a nozzle or orifice through which the high-pressure water and abrasive mixture is ejected to perform the cutting. The head is often adjustable to control the cutting angle and distance from the workpiece.

Tool Mounting Bracket:

A tool mounting bracket or flange holds the cutting head securely in place on the robot arm. It allows for easy attachment and removal of the cutting head.

Robot Controller:

The robot controller is responsible for programming and controlling the robot's movements and actions during the cutting process. It interprets the cutting program and ensures precise motion.

Teaching Pendant:

A teaching pendant is a handheld device that allows operators to interact with and program the robot. It can be used to manually guide the robot's movements and input cutting parameters.

End-of-Arm Tooling (EOAT):

In addition to the cutting head, specialized end-of-arm tooling may be used to hold and manipulate the workpiece. This can include grippers, fixtures, and clamps designed for specific applications.

Motion Control Software:

Software is used to create cutting paths, plan toolpaths, and control the robot's movements. It plays a crucial role in ensuring precision and efficiency in the cutting process.

Safety Features:

Safety components, such as emergency stop buttons, protective barriers, and light curtains, are important to ensure the safety of operators and prevent accidents.

Collision Detection Systems:

Collision detection systems are designed to prevent the robot arm from colliding with other objects or the workpiece during operation. These systems enhance safety and protect the equipment.

High-Pressure Water Delivery System:

A high-pressure water delivery system supplies the cutting head with the required water and abrasive mixture at the specified pressure. This includes pumps, hoses, and filters.

Computer-Aided Design (CAD) Software:

CAD software is used for designing and programming the cutting paths and generating the cutting program that the robot will follow.

Cameras and Vision Systems:

Vision systems and cameras can be integrated to provide real-time feedback and image recognition, allowing the robot to adjust its movements based on the workpiece's shape and position.

These accessories and components work together to ensure the precision and efficiency of robot waterjet cutting. The selection of specific accessories depends on the requirements of the application, the materials being cut, and the level of automation desired.

If you are looking for robot waterjet cutting system suppliers or Waterjet parts Coil 103263 suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

wwaterjet

wwaterjet