Overview of Waterjet robot Cutting Technology

Waterjet robot cutting is a versatile cutting technology that utilizes a high-pressure stream of water to cut through various materials. This process is often enhanced by mixing abrasive particles with the water stream, which increases its cutting power and allows it to handle harder materials

What are the Automotive Sector Materials That a Waterjet robot Can Cut?

Metal materials: Waterjet cutting can handle a variety of metal materials, such as steel, aluminum alloy, stainless steel, etc. It can be used to cut metal components such as automobile body panels, frames, engine parts, and suspension components.

Glass: Waterjet cutting is a common application for cutting automotive glass. It can accurately cut front windshield glass, side window glass, rear window glass, etc., ensuring the accuracy of size and shape.

Plastic: Waterjet cutting can handle a variety of plastic materials, such as polyethylene, polypropylene, polyvinyl chloride, etc. It can be used to cut automotive interior parts, plastic coverings, seals, etc.

Composites: Many modern cars use composite materials such as carbon fiber reinforced composites (CFRP) and glass fiber reinforced composites (GFRP). Waterjet cutting technology can efficiently cut these composite materials for use in manufacturing lightweight automotive structures and components.

Rubber: Waterjet cutting is suitable for cutting rubber materials, such as rubber seals, rubber pipes, etc. It enables precise cutting and processing.

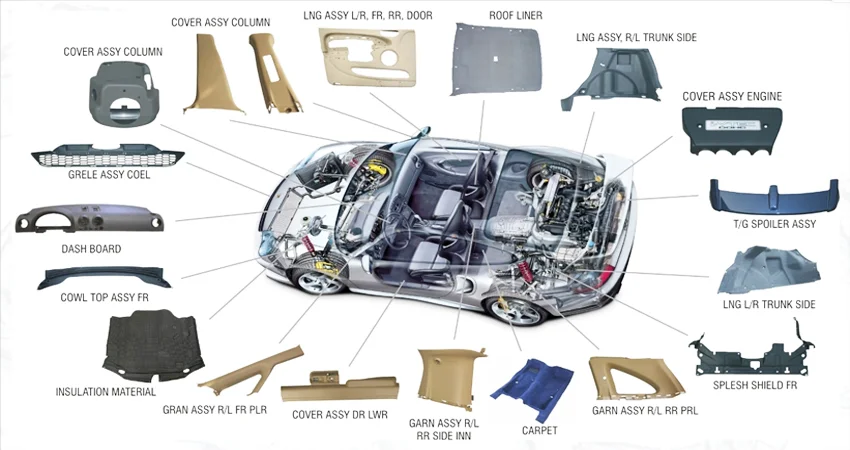

Vehicle Interiors Applications of Waterjet robot Technology

Cutting seat fabrics

Waterjet technology can precisely cut seat fabrics such as fabric and leather.

It can cut out various parts of the seat kit according to the design requirements. Make sure the cutting edges are flat and burr-free to provide high-quality seat fabrics.

Making carpets and floor mats

Water jet technology can be used to make automotive carpets and floor mats.

It is able to accurately cut the carpet to the shape and size,

It is alsoable to make concave and convex cuts when needed, to fit the shape of the vehicle’s floor pan.

Cutting and engraving center console panels

Waterjet technology can be used to cut and engrave center console panels, such as dashboards and central control panels. It enables fine cutting and engraving to create complex control panel designs and meet the requirements of different vehicle models.

Making door trims and interior panels

Waterjet technology can be used to cut and process door trims and interior panels.

It allows for precise cutting to create door trim shapes and sizes that meet design requirements.

It can perform complex contour cuts and chamfers when required.

Carving and decorative parts production

Waterjet technology can also be used for interior engraving and decorative parts production.

By controlling the speed and pressure of the water jet, beautiful engraved patterns and decorative patterns can be created for interior panels, steering wheels, gear shifters and other components.

Benefits of Using Waterjet robot in the Automotive Sector.

High-precision cutting

Waterjet technology can achieve high-precision cutting, whether it is for materials such as metal, composite materials, glass or plastic, it can achieve fine cutting effects.

This is very important for the automotive industry, as the size and shape requirements of automotive parts are often quite stringent, and waterjet technology is able to meet these high-precision requirements.

No heat-affected zone

Waterjet cutting is a cold processing method that does not produce a heat-affected zone (HAZ). Compared with traditional thermal cutting methods, such as laser cutting and plasma cutting, waterjet technology does not cause deformation, oxidation or hardening of the material, thus maintaining the original properties of the material.

Multi-material adaptability

Waterjet technology is suitable for cutting and processing a variety of materials, including metals, composites, glass, plastics and rubber. In automobile manufacturing, different materials are often used for different parts and components, and waterjet technology can handle these diverse materials and provide a full range of solutions.

Burr-free and good surface quality

Waterjet cutting can produce smooth, burr-free cutting edges without the need for additional secondary processing. This is particularly important for automotive interior and exterior parts, which often require good surface quality and tactile feel.

Environmental protection and energy saving

Water jet cutting is an environmentally friendly and energy-saving cutting technology. Compared to traditional thermal cutting methods, waterjet cutting does not produce harmful gases, waste heat or harmful by-products.

At the same time, the water used in the water jet cutting process can be recycled, reducing water consumption and waste of water resources.

Where to Find a CNC Waterjet robot Cutting Machine?

As the first waterjet cutting robot integrator in China, win win company has truly achieved diversification, differentiation and customization.

The selection of robots from ABB, FANUC, YASKAWA to KUKA, and we can provide the installation structure of sitting or ceiling type, which meets the cutting requirements of customers for cutting different parts of the automotive interior.

Double-station and rotary worktable greatly improve work efficiency.

From 3.8L/min to 100hp 7.8L/min large flow rate, from 60000 psi to 90000psi cutting pressure, not only realize the one-drag 6 robot arm, but also realize the cutting of ultra-thick and ultra-hard automotive interior materials.

Win win has been committed to providing customers with satisfactory waterjet cutting solutions.

The customer groups it serves range from Antolin, BMW, TOYOTA and other automotive interior production companies to military enterprises with 300 mm ultra-thick metal, which has been widely praised by customers.

As the pioneer of ODM service in the waterjet cutting industry, win win has been practicing customer supreme and win-win cooperation

Whats the basic structure of WINWIN Waterjet robot cutting machine?

| 1. | ABB2400/16 ROBOT ARMS and IRC5 robot control system |

| 2. | 60,000PSI Screamline SL-VI Waterjet Intensifier Pump |

| 3. | Safety System |

| 4. | General control system |

| 5. | Cooling system and water treatment system |

1. ABB2400/16 ROBOT ARMS and IRC5 robot control system

The ABB 2400/16 robot arms can be integrated with a waterjet cutting system to perform precise and automated cutting tasks. The robot arms are designed to handle heavy payloads and have a long reach, making them suitable for manipulating the waterjet cutting head and positioning it accurately on the workpiece.

The ABB robot arms and IRC5 control system can be seamlessly integrated into an overall waterjet cutting system. This integration involves connecting the robot arm to the waterjet cutting head and coordinating their operation through the control system. The integration allows for synchronized and automated cutting processes, improving efficiency and productivity.

2. 60,000PSI Screamline SL-VI Waterjet Intensifier Pump

A waterjet robot intensifier pump is a key component of a waterjet cutting system that provides the high-pressure water needed for the cutting process. It is specifically designed to generate and maintain the required water pressure for efficient cutting operations.

The pump uses a reciprocating piston mechanism to intensify the water pressure. It takes the incoming low-pressure water and compresses it to the desired high-pressure level required for cutting. The pump typically operates at pressures ranging from 30,000 to 90,000 pounds per square inch (psi) or higher, depending on the specific application.

The waterjet robot intensifier pump is integrated with the robotic system that controls the movement and positioning of the waterjet cutting head. The pump provides the high-pressure water to the cutting head through a series of hoses and fittings, allowing the robot to accurately direct the waterjet for cutting operations

3. Safety System

The safety system for a waterjet robot involves several measures to ensure the safe operation of the robotic system and protect operators and bystanders from potential hazards.

1.Emergency Stop (E-stop) Buttons: E-stop buttons are easily accessible switches that, when pressed, immediately halt the robot’s operation. They are strategically placed around the robot and within reach of operators in case of an emergency or any unsafe situation.

2. Safety Fencing and Barriers: Physical barriers, such as safety fencing or light curtains, can be installed around the robot’s workspace to prevent unauthorized access and ensure that operators maintain a safe distance from the robot during operation. Light curtains use infrared beams to detect the presence of objects or people and can trigger an immediate stop if the beam is interrupted.

4. General control system

A general control system for a waterjet robot involves the coordination and management of various components to control the robot and the waterjet cutting process.

Robot Controller: The control system includes a dedicated robot controller that interfaces with the robot arm and manages its movements. The controller receives commands and instructions, processes them, and generates the necessary signals to control the robot’s motors and actuators

Human-Machine Interface (HMI): The control system typically incorporates an HMI, which provides a user-friendly interface for operators to interact with the robot and control the waterjet cutting process. The HMI allows operators to input cutting parameters, adjust settings, monitor the system’s status, and access diagnostic information.

5. Cooling system and water treatment system

A waterjet robot cutting system requires a cooling system and a water treatment system to ensure proper functioning and longevity of the equipment

Cooling System:

The cooling system in a waterjet cutting system serves to maintain optimal operating temperatures for the various components, including the intensifier pump, cutting head, and high-pressure plumbing. It prevents overheating and helps prolong the lifespan of the equipment

Water Treatment System:

Water treatment is essential to maintain water quality, prevent nozzle clogging, and protect the cutting system from damage caused by impurities

cooling and water treatment systems are crucial for maintaining the performance and reliability of a waterjet cutting system. They help prevent equipment damage, reduce downtime, and ensure consistent cutting quality

wwaterjet

wwaterjet