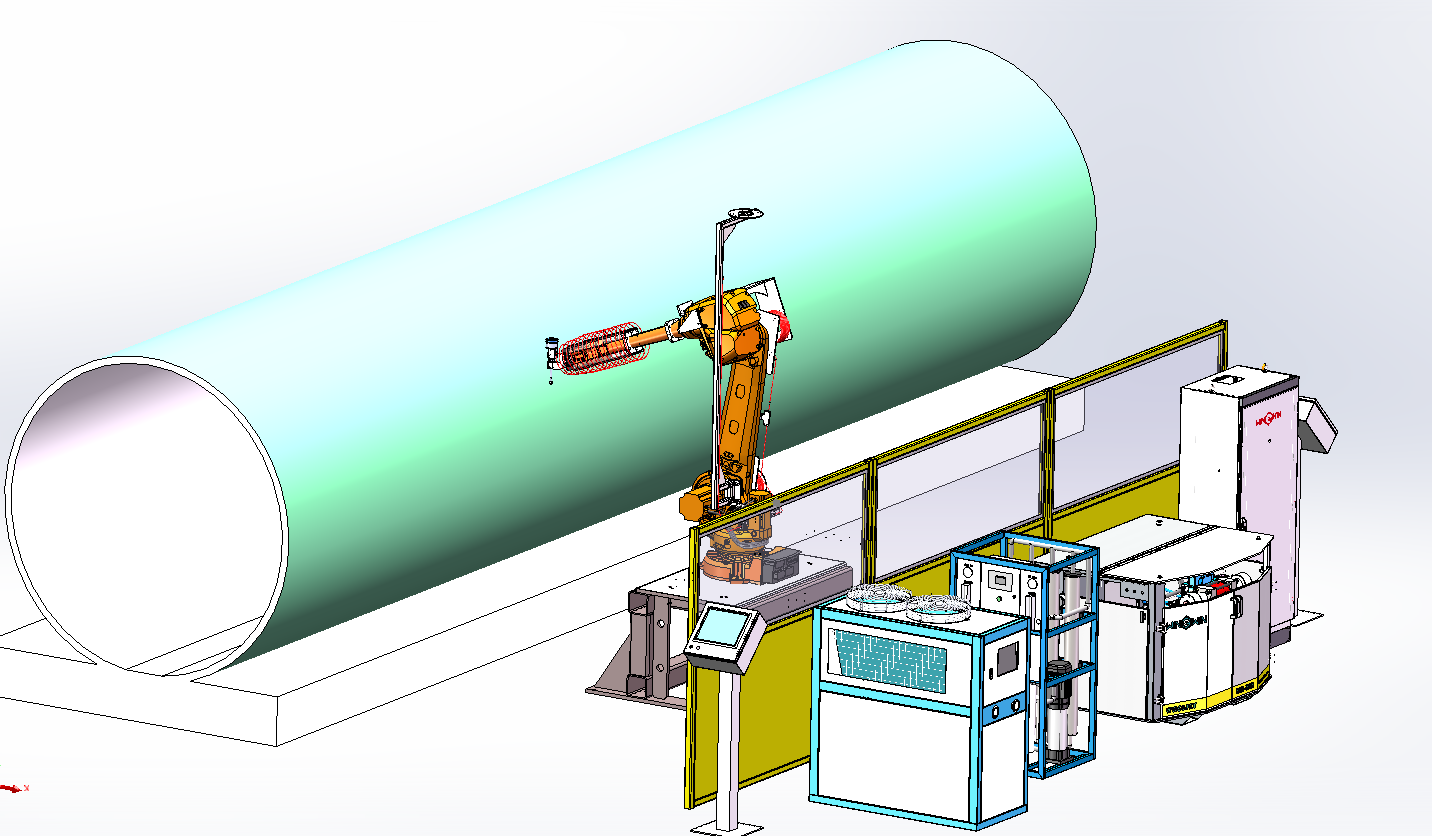

How to use waterjet robot to cut cylinder body of tank?

Win-Win Waterjet provide waterjet robot solutions for customer

Win-Win Waterjet get an inquiry from customer

Cutomer produtcs: produce a large volume FRP tanks for liquid storage, water tratement system and also FRP tanks for more other aplications.

Cutting requirment : customer need to cut various shape on the body of the tanks: in-out pipe conection, inspection holes, ventilation hole and so on.

We are interested to buy a MOBILE Cutting Water Jet System for integration in our production process.

The basic specifications are:

Power – 20-22 KWh;

Pressure – 3000 bar;

Water consumption – 5-6 liters/hour;

Nozzle - 0.4mm;

Rebound kick force on lance – 6kgf;

This equipment must can be able to used both: manually (by means of a lance/spear) and attached to a robot for repetitive and complex cutting design.

waterjet robots excel at cutting complex shapes and designs on water tanks efficiently. The computer-controlled systems of waterjet robots allow for

precise and intricate cutting paths, making them well-suited for handling complex shapes and designs.

Waterjet cutting technology enables the robots to cut through various materials, including metals, composites, glass, and plastics, with high precision

and accuracy. This versatility allows waterjet robots to handle different types of water tanks, regardless of their shape or design.

Whether the water tank has a cylindrical, rectangular, or irregular shape, waterjet robots can navigate and cut through complex curves and contours

with ease. The flexibility of waterjet cutting makes it an ideal solution for cutting intricate patterns, internal structures, or customized designs on water tanks.

wwaterjet

wwaterjet