Waterjet cutting services

Waterjet cutting services are a type of precision cutting service that utilizes a high-pressure stream

of water mixed with an abrasive substance to cut through various materials. It is a versatile and

efficient cutting method that can be used for a wide range of applications in industries such as

manufacturing, aerospace, automotive, and architecture.

Here's an overview of how waterjet cutting works:

Equipment:

Waterjet cutting machines consist of a high-pressure pump, a cutting head, and a control system.

The pump generates high-pressure water, typically around 60,000 to 90,000 pounds per square inch (psi).

Abrasive Mixing:

In most cases, an abrasive substance such as garnet is mixed with the water to enhance the cutting

power. The abrasive particles are added to the water stream before it reaches the cutting head.

Cutting Process:

The high-pressure water stream exits the cutting head at a speed of several times the speed of sound.

The abrasive particles in the stream erode the material being cut, creating a narrow, precise cut. The

cutting head is moved along a programmed path guided by the control system.

Material Compatibility:

Waterjet cutting can be used on a wide range of materials, including metals (such as steel, aluminum,

and titanium), ceramics, glass, stone, composites, plastics, and more. It is suitable for materials that

are sensitive to heat, as it is a cold cutting process.

Precision and Versatility:

Waterjet cutting offers high precision, with the ability to achieve intricate shapes and tight tolerances.

It is a versatile method that can handle both thin and thick materials, and it can cut through stacked

layers as well.

Benefits:

Some advantages of waterjet cutting include minimal material waste, no heat-affected zone (HAZ) or

distortion, no mechanical stress on the material, and the ability to cut a wide range of materials without

the need for tool changes.

To access waterjet cutting services, you can often find specialized companies or fabrication shops that

offer this service. They will have the necessary equipment and expertise to handle your cutting needs.

When reaching out to a service provider, it's important to provide them with detailed specifications,

including the material type, thickness, and desired cut dimensions, to ensure they can meet your

requirements.

Waterjet manufacturers

Flow International Corporation:

Flow is one of the pioneers in waterjet technology and offers a wide range of waterjet cutting systems.

They provide both pure waterjet and abrasive waterjet machines for various industrial applications.

OMAX Corporation:

OMAX specializes in advanced abrasive waterjet systems and is known for its precision cutting technology.

They offer a range of versatile and efficient machines suitable for both small-scale and large-scale production.

Bystronic: Bystronic is a leading manufacturer of advanced cutting and laser systems. They offer waterjet

cutting machines that feature high cutting speeds and accuracy, catering to industries like aerospace,

automotive, and architecture.

Jet Edge: Jet Edge is a manufacturer of ultra-high-pressure waterjet systems. They provide a wide range of

water jet machines capable of cutting through thick materials and handling complex cutting projects.

WARDJet: WARDJet is a manufacturer of custom waterjet cutting solutions. They offer a range of machines

designed for precision cutting across various industries, including metal fabrication, aerospace, and automotive.

Techni Waterjet: Techni Waterjet is known for its advanced waterjet cutting systems. They offer a variety of

machines, from small entry-level models to large industrial systems, catering to different production needs.

KMT Waterjet Systems: KMT is a global manufacturer of waterjet cutting systems and related components.

They provide high-pressure pumps, cutting heads, and complete waterjet systems, offering cutting solutions

for a wide range of materials.

Shenyang Win-Win Waterjet

As the first waterjet cutting robot integrator in China, win win company has truly achieved diversification,

differentiation and customization.

The selection of robots from ABB, FANUC, YASKAWA to KUKA, and we can provide the installation structure

of sitting or ceiling type, which meets the cutting requirements of customers for cutting different parts of

the automotive interior.Double-station and rotary worktable greatly improve work efficiency.

From 3.8L/min to 100hp 7.8L/min large flow rate, from 60000 psi to 100000psi cutting pressure, not only

realize the one-drag 6 robot arm, but also realize the cutting of ultra-thick and ultra-hard automotive interior

materials.

The win-win 100,000 ultra-high pressure pump is widely used in cutting ultra-thick metal materials in aerospace,

nuclear industry and other industries.

WinWin 3 axis waterjet cutting system is widely used in the glass industry.

Its high precision and no thermal deformation make it an ideal choice for cutting, engraving and processing glass.

The following are some applications of WinWin 3 axis system in the glass industry:

Flat cutting:

WinWin three-axis water cutting system can be used to cut glass on flat surfaces, such as customized glass doors,

windows, glass tabletops, etc. Because waterjet cutting does not generate heat, it will not cause thermal cracks

or deformation of the glass edge.

Complex pattern cutting:

This system can perform high-precision cutting of complex patterns, such as patterns, text and artwork, according

to design requirements. This is useful for the manufacture of glass crafts, decorative glass and custom glass items.

Glass Engraving:

The WinWin 3-axis waterjet system can be used for glass engraving to create unique textures and patterns.

This application is attractive for decorative products such as glass art and engraved wall panels.

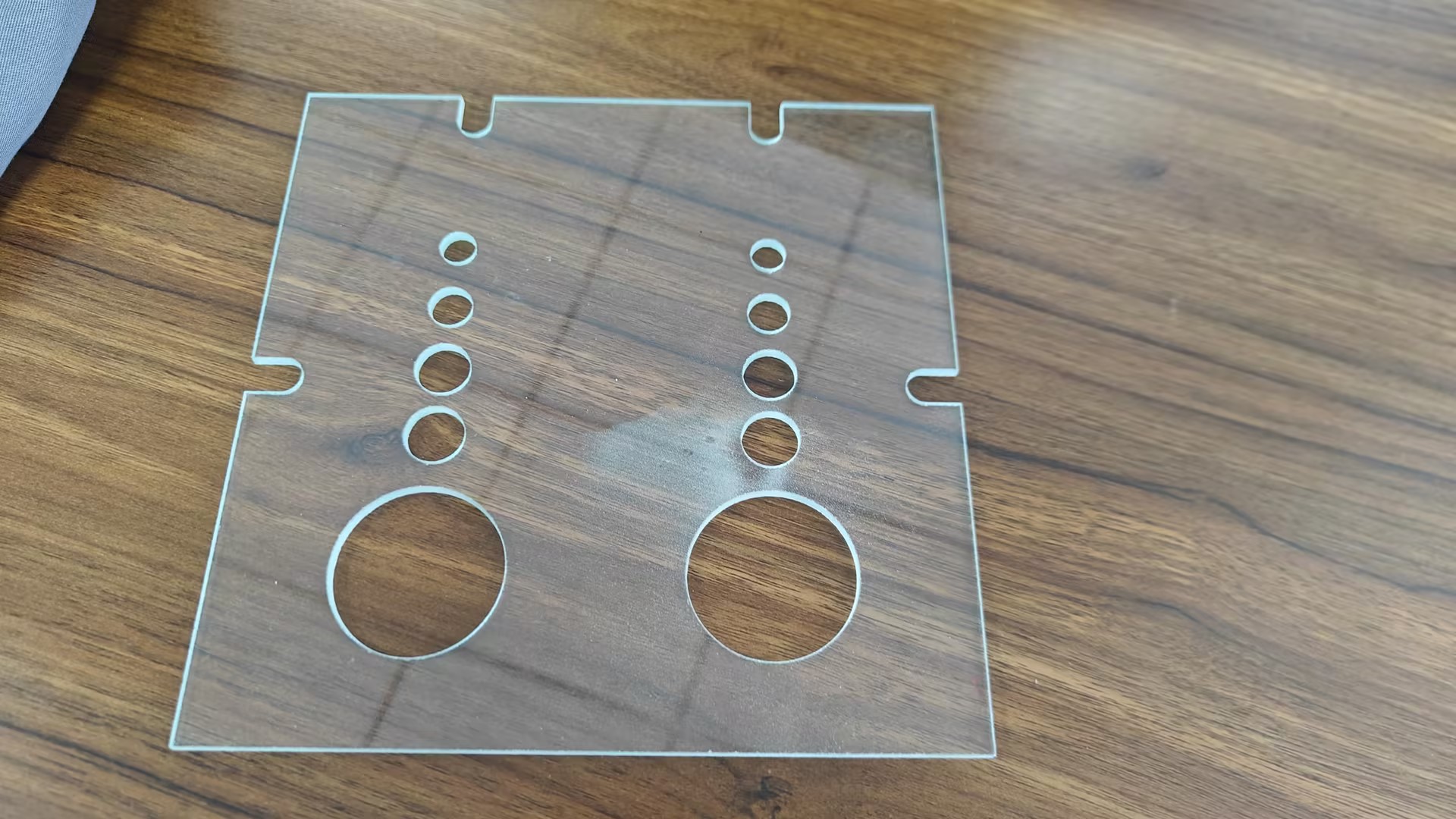

Hole and Cutout Creation:

Using high-precision cutting technology, the WinWin system can easily create holes and cuts in glass. This is

useful when manufacturing products that require the installation of sockets, lighting fixtures, or other accessories.

Composite Cutting:

For glass products that use multiple layers or composite materials, such as laminated glass, waterjet systems

can effectively cut without affecting the material's properties.

WinWin 5 axis waterjet cutting system applications in cutting ceramic tiles.

The five-axis control of this advanced system allows it to cut at a variety of angles and directions, providing

the tile industry with greater flexibility and precision.

The following are some applications and advantages of WinWin cutting ceramic tiles:

Multi-angle cutting:

5-axis control allows the WinWin system to cut in multiple axes, which is useful for designs that require creating

bevels, three-dimensional patterns or complex shapes on the tile surface.

Three-dimensional cutting:

Through the 5 axis cutting system, three-dimensional cutting of ceramic tiles can be achieved, creating more

creative and artistic designs.

Custom Design Cutting:

Utilizing advanced 5 axis control, tiles can be cut to your customers’ custom needs to create unique patterns,

text or logos.

Complex edge processing:

The 5-axis waterjet system can precisely process the edges of ceramic tiles, including bevels, curves and other

complex shapes, thereby improving the beauty and quality of the edges.

wwaterjet

wwaterjet