Due to the large demand in the market and the increasing emphasis on home decoration effects during house decoration, the customer contacted us and wanted to purchase a complete set of CNC water cutting equipment for his factory to create greater economic benefits.

Now let’s understand what the following stone parquet is and what are its classifications?

Stone parquet is a highly valuable product among stones and is widely used in architectural decoration.

Parquet products include flat parquet, three-dimensional parquet, relief parquet, curved plate parquet, solid column parquet, and mosaic parquet. Each of these parquet products has its own characteristics, so the processing technology is different.

How to classify ceramic tile parquet products?

1. According to the geometric shape of the parquet: rectangular and square parquet; circular parquet, oval parquet; fan-shaped parquet; regular polygonal parquet.

2. Divided by installation area: lobby parquet; guest room parquet; lounge, coffee shop, piano bar parquet; living room, restaurant parquet; entrance parquet; bathroom parquet; stair and step parquet.

From the classification of the product's use range in space: it can be divided into two types: floor mosaic and wall mosaic; floor mosaic is a type of ceramic tile mosaic that is laid on the ground; wall mosaic is a type of ceramic tile mosaic that is applied to the wall;

4. From the classification of product surface technology: generally it can be divided into glazed tile parquet, microcrystalline tile parquet, and waterjet processed tile parquet; glazed tile parquet refers to a type of ceramic tile surface that is glazed and printed after high-temperature sintering. Ceramic tile parquet products, microcrystalline tile parquet is a type of tile parquet product whose surface is covered with microcrystalline frit and then sintered at high temperature. Waterjet processed tile parquet refers to the application of waterjet cutting into patterns, and then high-strength resin pasting and joining together. A type of shaped tile parquet.

However, most customers have encountered a problem when decorating. The structure of their own house is not regular. Other homes are fine, but it is a big problem for ceramic tiles that need to be laid over a large area, because the ceramic tiles are shipped from the factory. The size is basically 800×800 mm or 600×1200 mm. It cannot be laid directly. It requires certain cutting and simple cutting. The decoration master can do it on site, but some special-shaped processing cannot be carried out. On-site operations can only be processed by water cutting, and the parquets designed by water cutting are exquisite, not only beautiful and elegant, but also highly precise and durable.

The above is an introduction to the types of parquet. Among the various types of parquet, a CNC water jet machine is the most suitable for our customers. They want to cut ceramic tile parquet, but the customer also raised his questions, such as the pattern of the ceramic tile parquet. We provide solutions for customers in terms of design, input-output ratio of the machine, cost accounting, recruitment of relevant personnel, whether we can help, equipment parameters of the machine, etc.

First of all, the customer consulted us about the relevant knowledge of ceramic tile parquet. What is ceramic tile parquet?

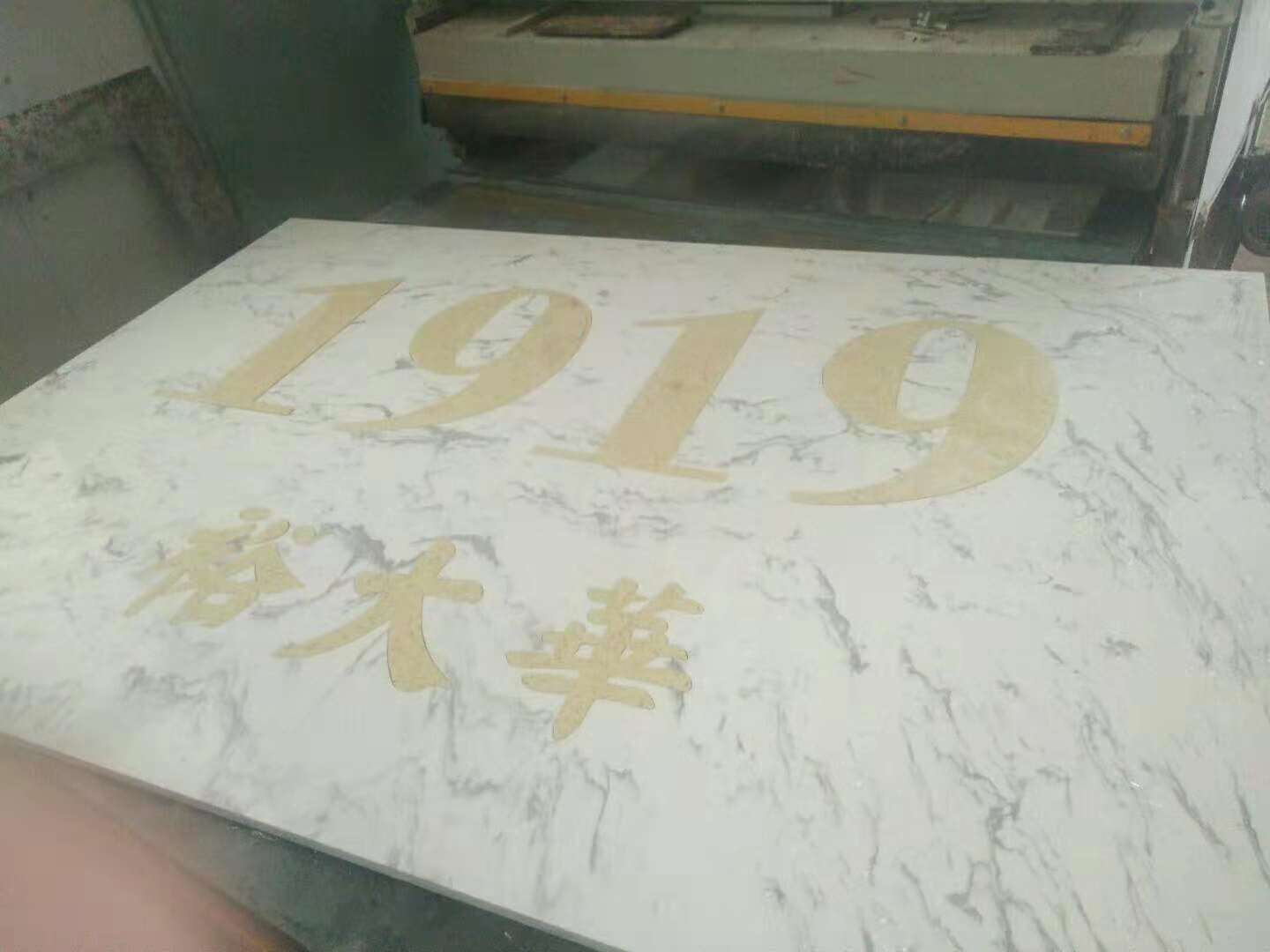

The most common waterjet parquet currently on the market is stone waterjet parquet. Stones of various colors are cut into required shapes using a waterjet, and then spliced together with glue. They are mainly used in star hotels, large shopping malls, villas, and home decoration. The living room, dining room and entrance hall are currently the best, most gorgeous and noble decorative products among stone decorations. Marble, granite, jade and artificial stone are all good material choices.

The process of cutting tile parquet using water jet cutting

We provide customers with a full set of ceramic tile mosaic patterns, which can be directly imported into the water cutting machine for use. There is no need to worry about the technical difficulties and mosaic ideas above. Before leaving the factory, our customers will process the drawings selected by the user. High-tech exquisite cutting

After the pattern is formed, workers will splice the pattern once, check whether there are any defects, and determine whether the size and size are normal before leaving the factory and going to the home for installation.

The following is an introduction to several options for ceramic tile parquet.

The first is a simple version of parquet, with single-sided wave lines and single-color ceramic tiles. If you want to pursue a simple space effect, the simple version of parquet can meet your needs. There is no cutting loss or combination plan to consider, and the operation is simple and efficient. As long as a wave line with pure personality is needed, even if there is a single type of tile inside, the effect will not be boring.

The second type is the medium version of parquet with wave lines + two-color ceramic tiles

This parquet style is richer and more elegant than monochrome tiles. Two ceramic tiles of the same specifications and different colors can be laid in diagonal, dot-matrix, stripe and other combinations to create a neat and elegant parquet plan.

The third type is the multi-wave wiring group

Wave lines with multiple edges, multiple colors, and different specifications give the space more beauty.

The fourth type is a high-end version of parquet with wave lines + double/multi-color ceramic tiles + cutting and paving.

With fine cutting and clever combination, ceramic tiles can bloom on the ground. The combination scheme with small color difference and meticulous lines makes the living room look warm and romantic. The larger the size, the more spacious the space will be, and the contrasting color combinations with obvious color differences will appear very individual and avant-garde.

These are several simple parquet plans. We also have more than 80 kinds of tile parquet plans. You can contact us to send them to you. We will give away tile parquet patterns for free.

During the purchase process, the customer also raised questions about how long it would take for the machine to recover its cost. We calculated for the customer the cases of our previous customers who purchased water cutting machines. We also took the Chinese market as an example.

The profit and labor price of water cutting processing in the Chinese market,

The hourly cost in China is about 40 yuan, ceramic tile parquet is about 400 yuan per square meter, and the net profit profit of other products is about 120 yuan per hour. If the water cutting machine works eight hours a day, the cost can be earned back in half a year.

After calculating the cost for the customer, we conducted on-site trial cutting. If you want to cut any material with water cutting, you can contact us at any time for trial cutting to check the cutting effect. After cutting, the customer is satisfied with the stability and accuracy of the machine. , cutting speed, etc. were very satisfied. We purchased the water cutting machine on the same day. After the installation, the customer also asked us to help recruit professionals. We screened and interviewed the customers. After selecting the staff, we It has conducted more professional training. WINWIN has specialized in water cutting for 20 years and has rich experience in technology and personnel training.

If you also need water cutting machines or ceramic tile mosaic patterns, please feel free to contact us at any time

wwaterjet

wwaterjet