How does a water jet cutting machine deal with dust?

Water jet cutting with high quality waterjet accessories, like other cutting processes, also generates a large amount of smoke and dust during operation. If it is simply discharged into the air, the harm caused can be imagined. Therefore, it is still necessary to properly handle this part of smoke and dust to avoid adverse effects on equipment and the environment. Do water jet cutting machines have any tricks in this regard?

Previously, the smoke and dust generated by water jet cutting with high quality waterjet accessories would be treated using natural or mechanical ventilation, but it had no effect on protecting equipment and personnel safety. After some improvement, a dust removal system was added to the water jet cutting machine, which not only separated a large amount of splashing and large particle dust inside the system, but also greatly improved the safety factor. Moreover, through modular design, it is convenient to provide modules of different sizes according to customer requirements and assemble them on-site.

Let's focus on its dust removal system, which actually divides the cutting platform into several equally wide partitions, and sets up a hopper in each partition that can both extract air and hold ash. Due to the fact that there is a damper at the end of the partition that is linked to the waterjet accessories cylinder, when the water jet cutting machine runs to any position, the corresponding damper will automatically open for dust removal.

Is the noise generated by water jet cutting loud?

The working medium used during water jet cutting is water, so the cutting effect is greatly different from other methods. However, one thing is the same: there will also be noise during cutting. Do you know how loud this noise is?

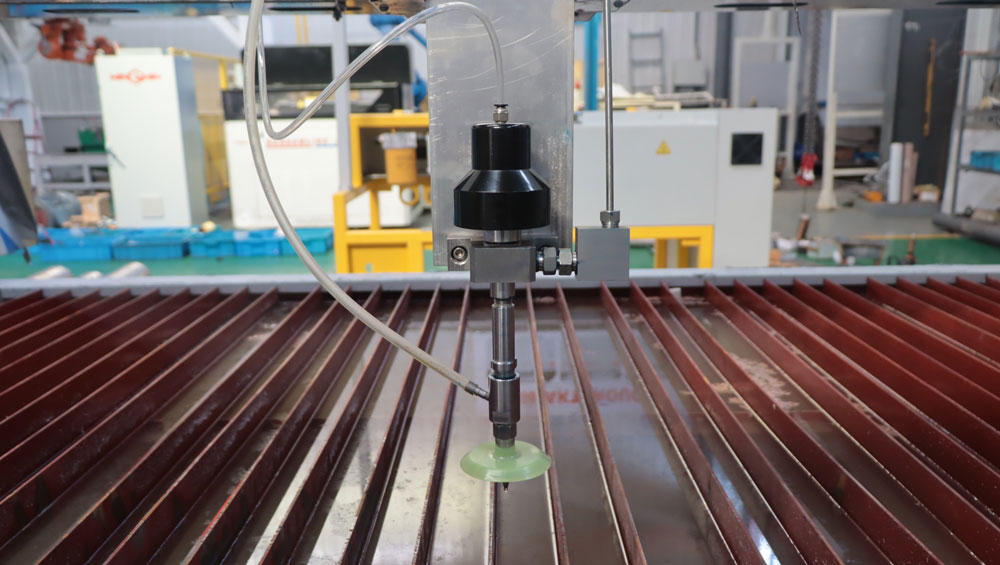

During the water jet cutting process, noisy products are inevitable, and under normal circumstances, this cutting and working of waterjet accessories noise ranges from 80-85dB. Practice has found that there is a certain relationship between noise and the distance between the sand tube and the workpiece. The larger the distance between the waterjet accessories abrasive nozzle of the water jet cutter and the cutting workpiece, the greater the noise. So for safety reasons, operators must wear relevant protective equipment.

In addition, the purity of the waterjet accessories abrasive used for water jet, the quality of water used, the thickness of the cutting material, and the quality of the gemstone itself will all have an impact on the cutting effect. To achieve the expected efficiency and quality under the premise of safety, the above aspects should be taken seriously.

Question related to adjusting the sealing pressure of water jet

When the pressure in the water jet reaches a certain height and high-pressure water occurs, corresponding resistance will also be generated in the system, which is called sealing pressure. Due to the impact of sealing pressure on the components of the water jet with high quality waterjet accessories, it is necessary to adjust it to protect the water jet and waterjet accessories.

Under normal circumstances, the higher the sealing pressure in the water jet, the greater the wear and tear on the components, but the cutting ability of the water jet becomes stronger as a result. In order to protect the waterjet accessories while maintaining cutting strength, the sealing pressure should be appropriately lowered. Also, if the water jet is used to cut brittle materials, the sealing pressure must be lowered, which can also have a good effect on reducing the damage rate of the workpiece.

The adjustment method for the sealing pressure of the water jet and waterjet accessories is actually very simple. Firstly, turn on the high pressure to reach the normal working pressure; Next, open the electrical cabinet door and reach the relay board. Simply rotate the button clockwise to reduce the sealing pressure.

The work of a water jet cutter mainly relies on the movement of the CNC cantilever or gantry to drive the cutting head, thus completing the entire cutting. Therefore, during the operation process, personnel should be prohibited from approaching the CNC cantilever to avoid accidental injury; The waterjet accessories cutting head is a component that comes into direct contact with the material being cut, so it is important to ensure that the cut material is placed flat to avoid damage to the components or injury to personnel.

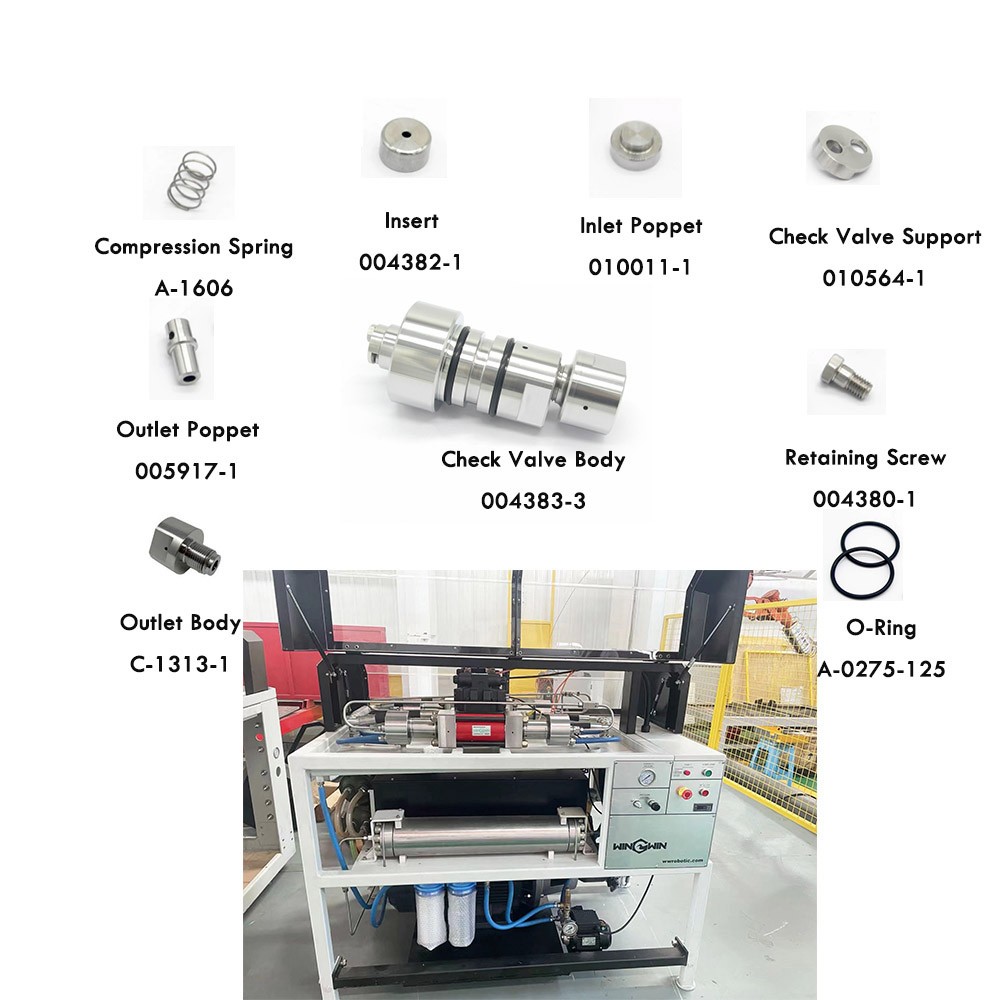

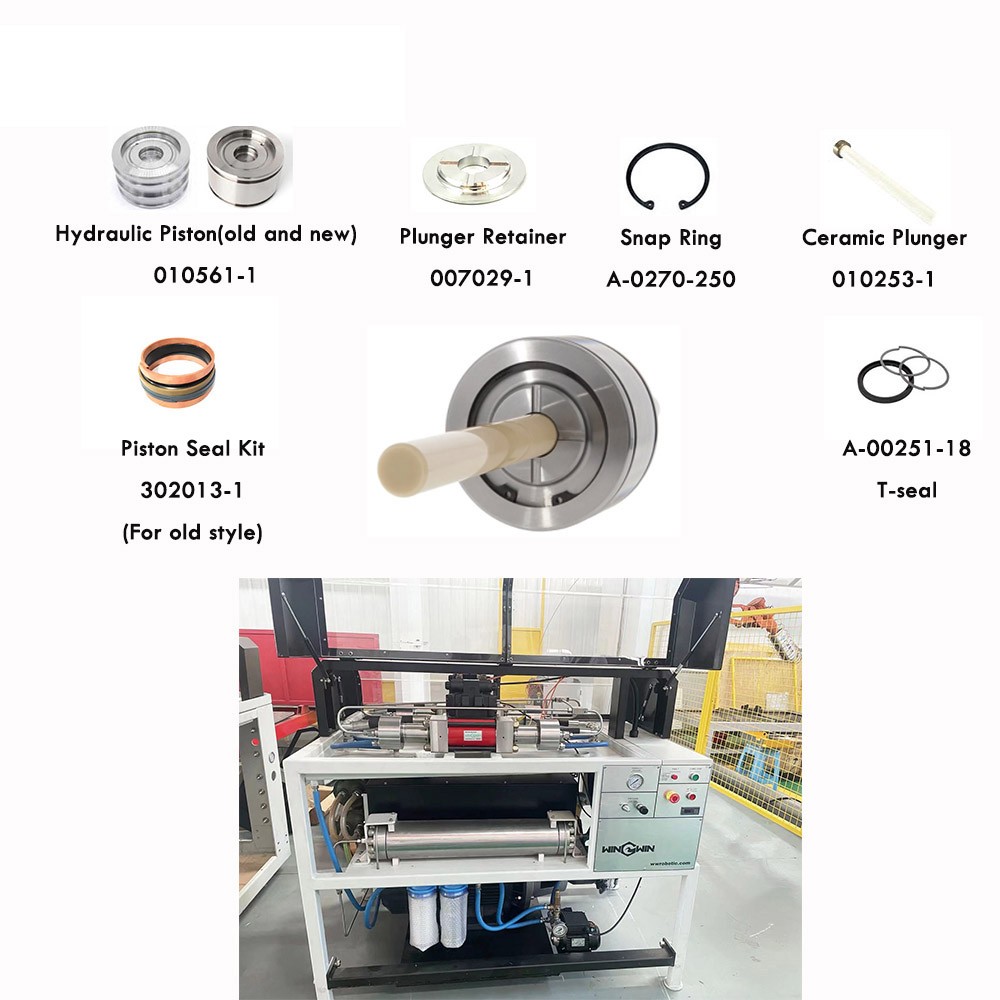

Secondly, to ensure the safety of waterjet accessories HP tube, the key is to prevent the leakage of high-pressure water. I would like to remind everyone that the waterjet accessories of water jet generally have regulations on the high-pressure usage range, and the pressure is also adjustable. In this regular maintaining way for waterjet accessories,you can reduce the downtime of your machine. In the same time,you can also prolong the service life of your water jet cutting machine. To avoid these problems,please select WIN-WIN waterjet accessories. WIN-WIN waterjet accessories can meet your high demand of your water jet cutting machine.

wwaterjet

wwaterjet