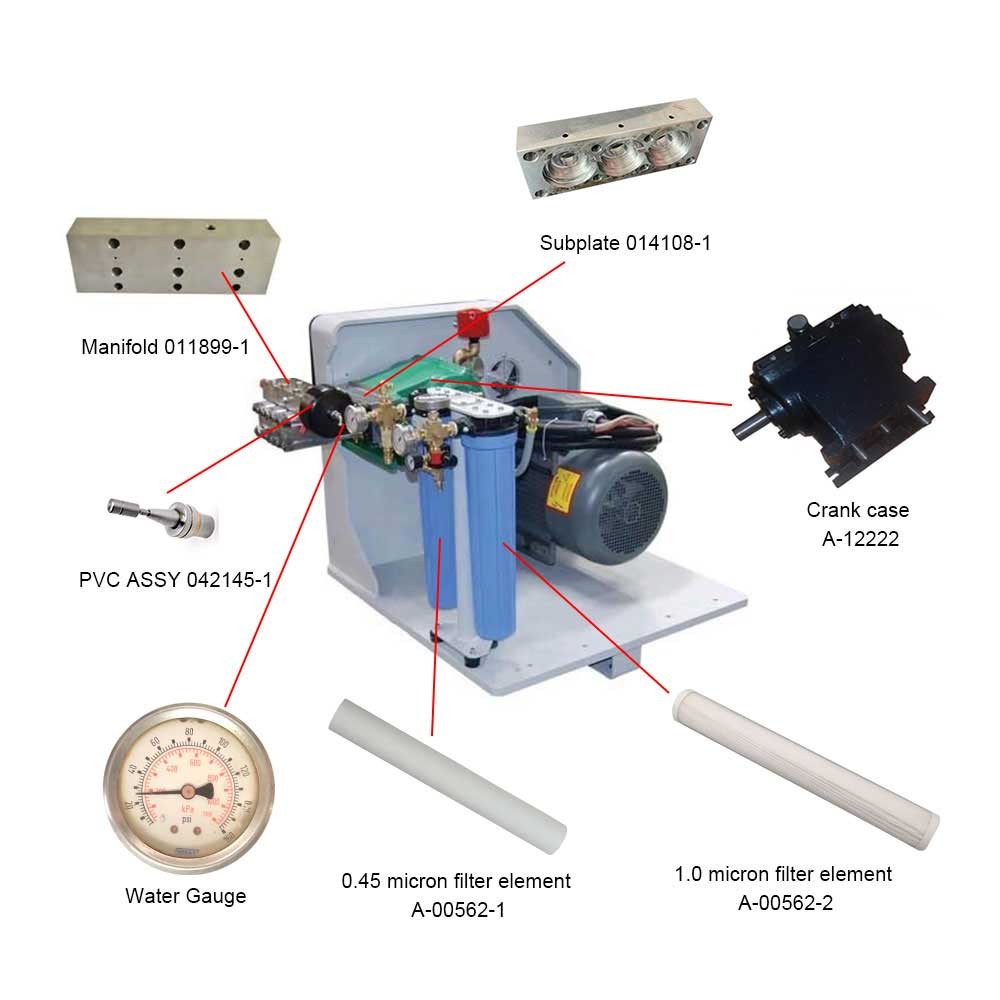

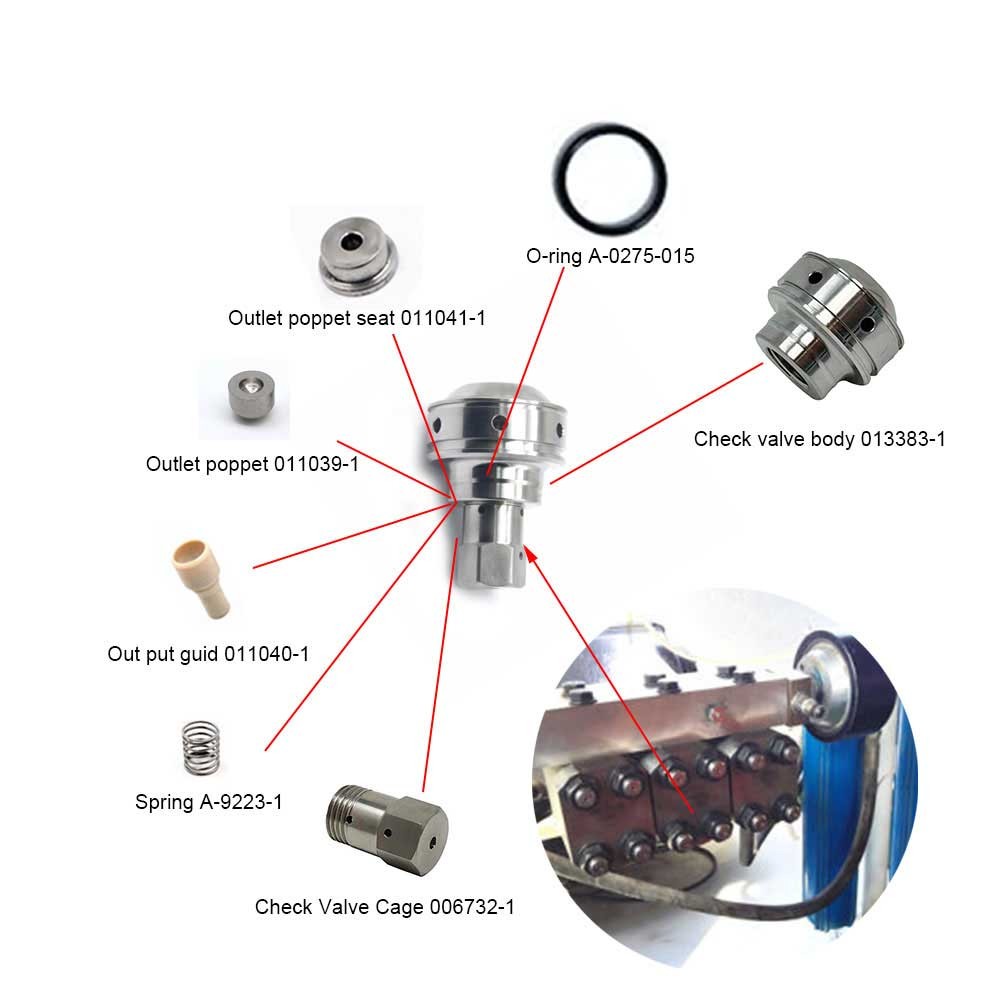

Direct Drive pump manifold 011899-1

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

A direct drive pump is a type of pump that is powered by an electric motor that is directly coupled to the pump impeller. Here are some advantages and disadvantages of using a direct drive pump:

Advantages:

Efficiency: Direct drive pumps are more efficient than belt-driven pumps as there is no power loss due to belt slippage or misalignment.

Maintenance: Direct drive pumps require less maintenance as there are fewer moving parts than belt-driven pumps.

Compact design: The direct drive design allows for a more compact pump, which can be useful in situations where space is limited.

Durability: Direct drive pumps are generally more durable than belt-driven pumps as there are fewer parts that can wear out or break.

Disadvantages:

Cost: Direct drive pumps are generally more expensive than belt-driven pumps due to their more complex and durable design.

Noise: Direct drive pumps can be noisier than belt-driven pumps as there is no belt to absorb sound and vibration.

Motor heat transfer: The direct coupling of the motor to the pump can result in the motor being exposed to the heat generated by the pump. This can potentially reduce the lifespan of the motor or require additional cooling mechanisms to be put in place.

Limited speed control: Direct drive pumps have limited speed control as the speed of the pump is directly tied to the speed of the motor. This can make it difficult to adjust flow rates or pressure settings.

wwaterjet

wwaterjet