Pure water jet and abrasive water jet

In essence, there are two types of water jet: pure water jet and abrasive water jet. The equipment is designed to use only pure water jet,abrasive water jet, or both. Whatever the form, the water must first be pressurized.

Intensifier pump

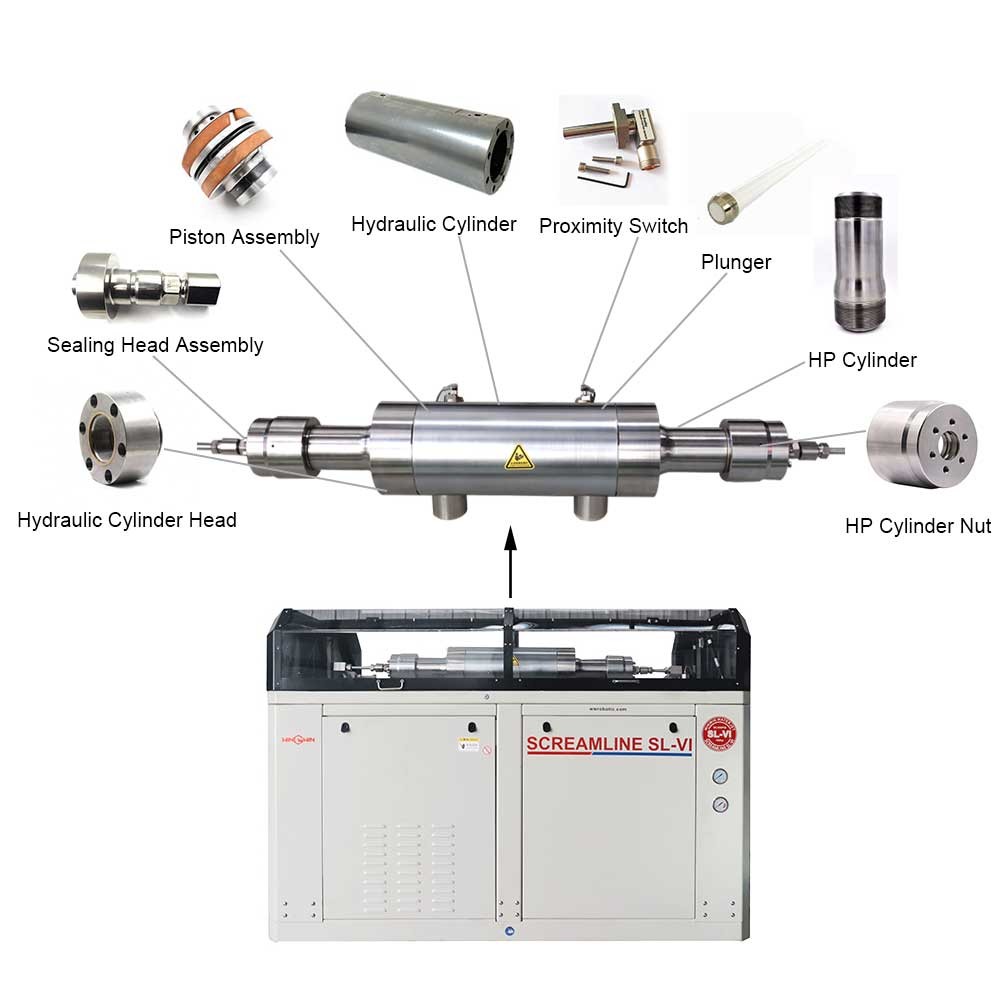

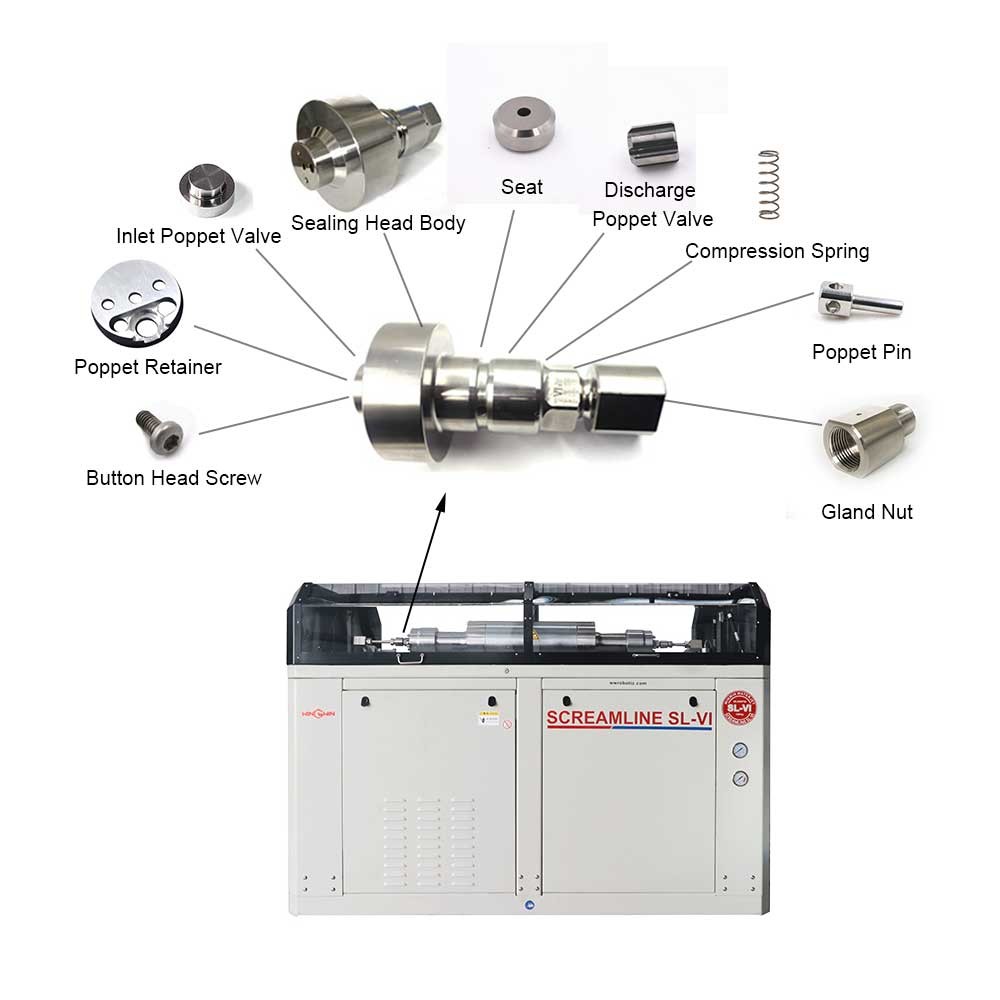

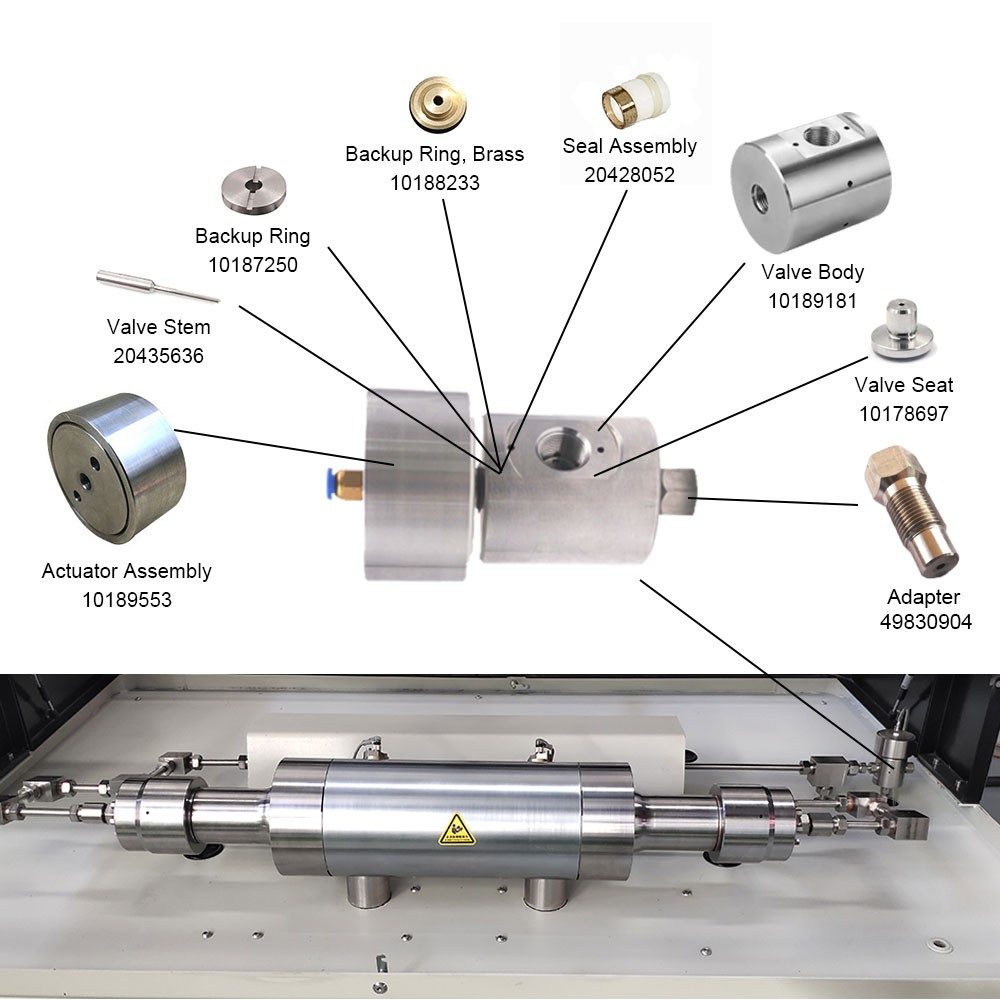

The intensifer pump is the core member of the water jet system. Pressurize the water and continuously output the water flow, so that the waterjet spare part cutting head can change the high-pressure water into supersonic water jet. Two types of pumps can be used for water jet applications - HP intensifier pump and direct drive pump.

Direct drive pump

The direct drive pump works in the same way as the low-pressure "pressure washer" used to flush the house or deck before painting. It is a three-stage pump that directly drives three pistons by a motor. Because of their simplicity and reliability, these pumps have been recognized by the wate rjet industry. Up to the time of publication, the maximum continuous working pressure that the direct drive pump can provide is 10% to 25% lower than that of the intensifer pump (20k to 50K for the direct drive pump and 40K to 60K for the intensifer pump).

Ultra high pressure intensifer pump

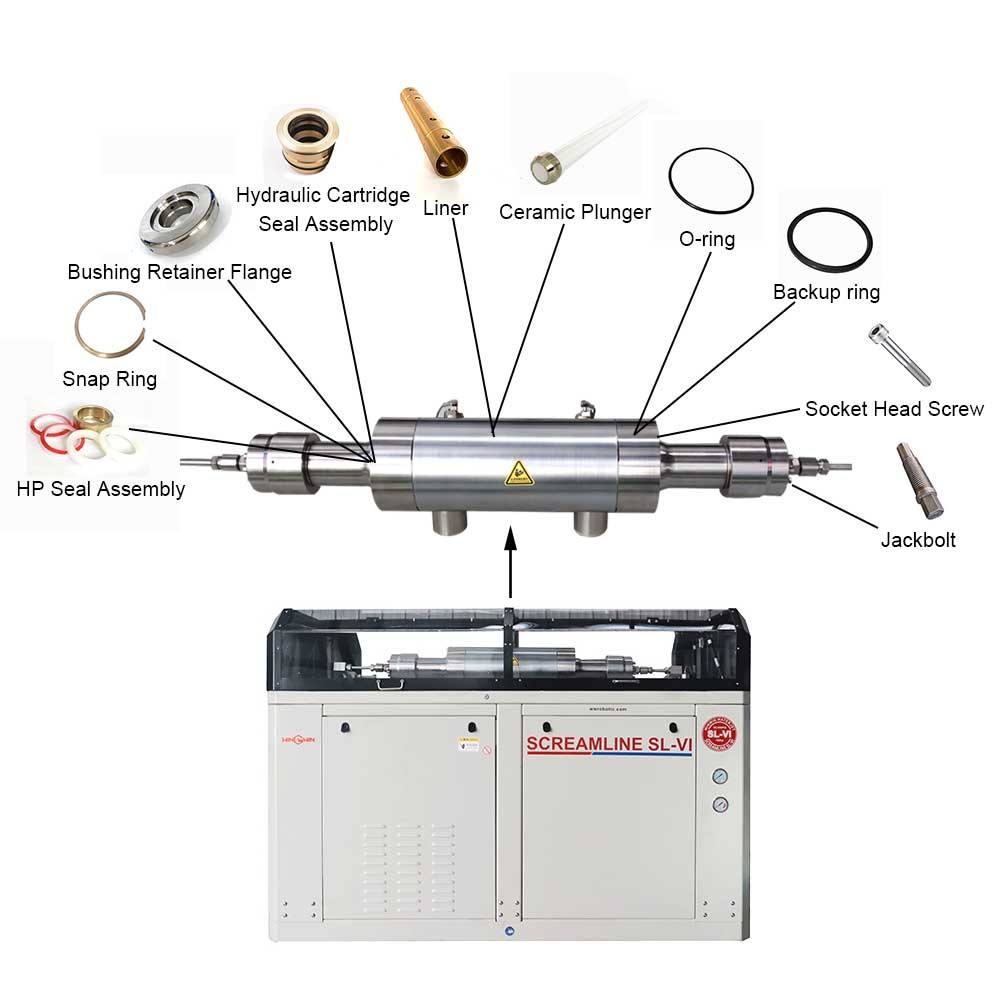

The waterjet spare part pipeline includes inlet filter, intensifer pump and shock absorber. Use the inlet filtration system to filter ordinary tap water - usually including a 1 micron filter cartridge and a waterjet spare part 0.45 micron filter cartridge. Before water leaves the pump and is piped to the cutting head, it first flows through the shock absorber. This large container cushions pressure fluctuations and ensures that the water delivered to the cutting head is stable and coherent. Without shock absorbers, you will be able to see and hear the pulsation of water flow, leaving a mark on the material being cut.

Principle and application of high pressure water cutting machine

The main parameters of high-pressure water jet technology are the water pressure at the waterjet spare part nozzle outlet, nozzle aperture, slab moving speed, slab thickness and material density. In order to save electricity and water, the aperture of the waterjet spare part nozzle should not be too large, but the aperture is too small. High pressure water will atomize at the moment when it leaves the nozzle, which can not achieve the purpose of cutting plates. Therefore, the selection of nozzle aperture is an important step in the design of high-pressure water jet. The simplest formula for flow calculation is: flow = cross-sectional area X flow velocity, and the cross-sectional area is squared with the nozzle diameter.

The power calculation of high-pressure water motor is a complex process. In practical application, we can only simplify it, and the complete and detailed calculation can only be a reference. It is the schematic diagram of a complete hydraulic system applied to high-pressure water cutting of fiber cement board. Considering the small diameter of the waterjet spare part nozzle, the calculation of pipeline water flow can be ignored in the ideal state. The most basic calculation can control the pressure of the oil pressure system. Once waterjet spare partnozzle is blocked, it is necessary to control the pressure of high-pressure water to ensure the safety of the whole system.The flow of pressurized water jet control system is: oil pump pressurization, electromagnetic directional valve, intensifier pump, high-pressure accumulator, high-pressure water directional valve,waterjet spare part nozzle and plate cutting.

The intensifier is a device that continuously generates high-pressure water. Through the reciprocating motion of the waterjet spare part plunger and the action of the one-way valve, the tap water with a certain pressure is sucked into the pressurization chamber of the intensifier, and the movement of the plunger pressurizes the pressure of the liquid water according to the pressurization ratio of the intensifier. Due to the continuous pressurization, the pressure fluctuation of high-pressure water will occur when the waterjet spare part plunger is reversed. The surplus of motor power is large, the nozzle aperture is small, the system is well sealed, and the pressure fluctuation will be reduced accordingly. Generally, the pressure of high-pressure water can fluctuate by 40-50% when the intensifier is reversed. If the pressure fluctuation range is too large during the use of the equipment, it will have a great negative impact on the product quality, Reducing system fluctuation is a necessary condition for stabilizing high-pressure water and high-pressure water cutting. At present, with the improvement of the technical level of various industries, the use of waterjet spare parthigh-pressure accumulator is becoming more and more popular, and the waterjet spare part quality is guaranteed. The rational selection of high-pressure accumulator can solve this problem.

Water jet technology has formed a plane spectrum of technology and products with pressure and power as the ordinate and jet as the abscissa. The application scope of high-pressure water jet technology has also expanded from simple mining industry to petroleum and chemical industry, aerospace, construction and transportation, metallurgy, municipal engineering and medicine.

wwaterjet

wwaterjet