Waterjet cutting machine for cutting different materials

Definitions of waterjet cutting and waterjet mosaic

Both waterjet cutting and waterjet mosaic are processing processes that use waterjet cutting machine for sale as equipment, and even so, there is still a big difference between the two processes, especially in terms of job results. Let a professional water jet manufacturer introduce water jet cutting and water jet mosaic to you.

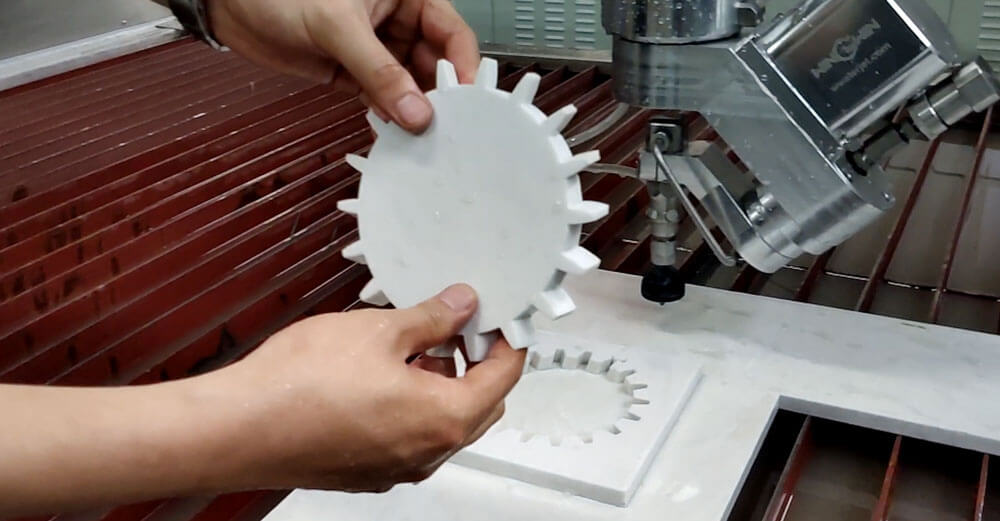

Waterjet cutting machine for sale is more flexible. Compared with other cutting methods, the advantage is that it can perform one-time cutting of any curve on any material, that is to say, its implementation is not limited by the type of material. Moreover, heat and harmful substances will not be generated during the cutting process, so it is a safe and environmentally friendly processing method.

Although waterjet mosaic is also cutting, it is cutting purposefully, in order to make materials into various patterns. When the water is pressurized to a certain extent and forms a high-speed jet through the nozzle, it only needs to add appropriate abrasives to cut stone, metal and other materials. In order to ensure the cutting effect, the cutting edge must be very flat during the waterjet mosaic process.

Reminder about waterjet cutting machine for sale cutting tiles

Waterjet cutting machine for sale can cut even hard stones, not to mention tile products. Therefore, waterjet cutting is the most widely used and effective one for cutting tiles. However, WIN-WIN as a manufacturer and seller of waterjet cutting machine for sale, has to explain to everyone the precautions when cutting ceramic tiles.

When we manually operate the waterjet to cut tiles, we must pay attention to the operation at the edge, we must advance along the main axis of cutting, and not use too much force to avoid breaking the tiles. In order to reduce the difficulty of cutting and improve the quality of cutting, the flatness of the tiles is checked, and also to prevent damage to the cutter head.

If you want to break the tile surface, don't use the force of the blade, but use the force of the whole fuselage to break it, the effect will be better, and it can also protect the waterjet blade to a certain extent.

What are the main causes of cracking in waterjet cutting of thicker workpieces?

During the water jet cutting process, it was found that some workpieces were cracked to varying degrees, and these workpieces all had one thing in common, that is, the thickness exceeded 40 mm. Is it possible that a workpiece of this thickness is particularly prone to cracking when cutting? This issue requires further analysis.

The workpiece to be cut is generally subjected to heat treatment such as quenching, so it is bound to contain residual stress inside, and the thickness of the workpiece determines the magnitude of the stress. It can be seen that the existence of stress is the main cause of waterjet cutting machine for sale. When the thickness is small, the stress along the top of the crack is in a plane stress state, and plastic flow is easy to occur at this time. However, as the thickness increases, the toughness will gradually decrease, and eventually physical fracture will occur due to the difficulty of plastic flow.

In view of this, the cutting method should be carefully selected when cutting thicker workpieces. If there is a slight discrepancy, the quality of the workpiece will be affected. The cracking of the workpiece has nothing to do with the performance of the waterjet cutting machine for sale process itself, so don't doubt its ability.

Common questions about waterjet cutting machines

How thick of steel can a water jet cut?

How thick can a water jet cut steel? Waterjet cutting machine for sale can cut through 9 inches of stainless steel. Anything thicker increases the cutting time significantly. Some applications reconfigure waterjet systems to cut through even 18-inch steel blocks.

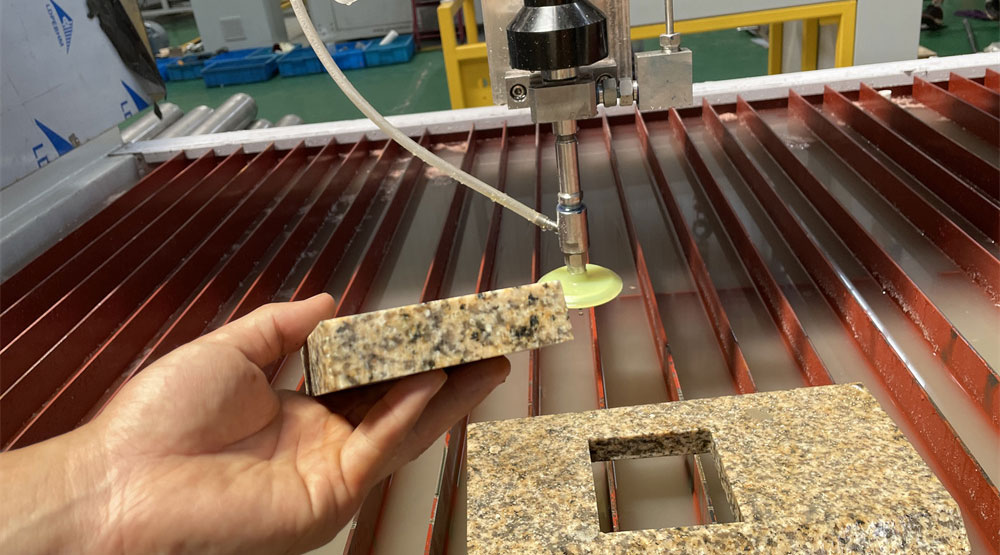

Can you waterjet cutting machine for sale cutting granite?

Can You Cut Granite With a Water Jet? Yes, it is easy to cut stone using a waterjet, and not only granite, as a high-pressure waterjet cutter is ideal for cutting stone such as marble too. A water jet can cut stone up to 12 inches, which is suitable for most stone-cutting applications.

What is the thickest material a waterjet can cut?

How thick can an abrasive waterjet cut? The high-level answer is that abrasive waterjets can cut through 12 inches of most materials. Many users report cutting material even thicker than that. Most abrasive waterjet cutting, however, is done in material that is 3 inches thick or less.

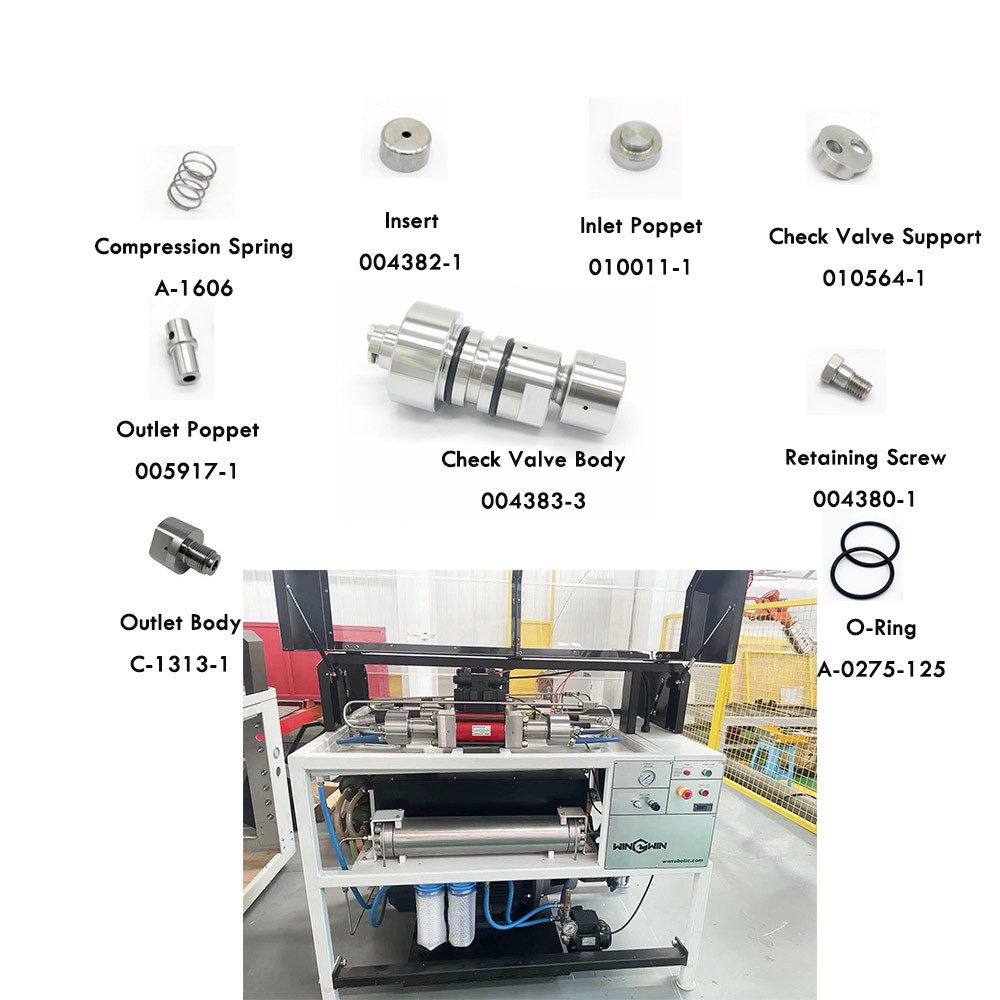

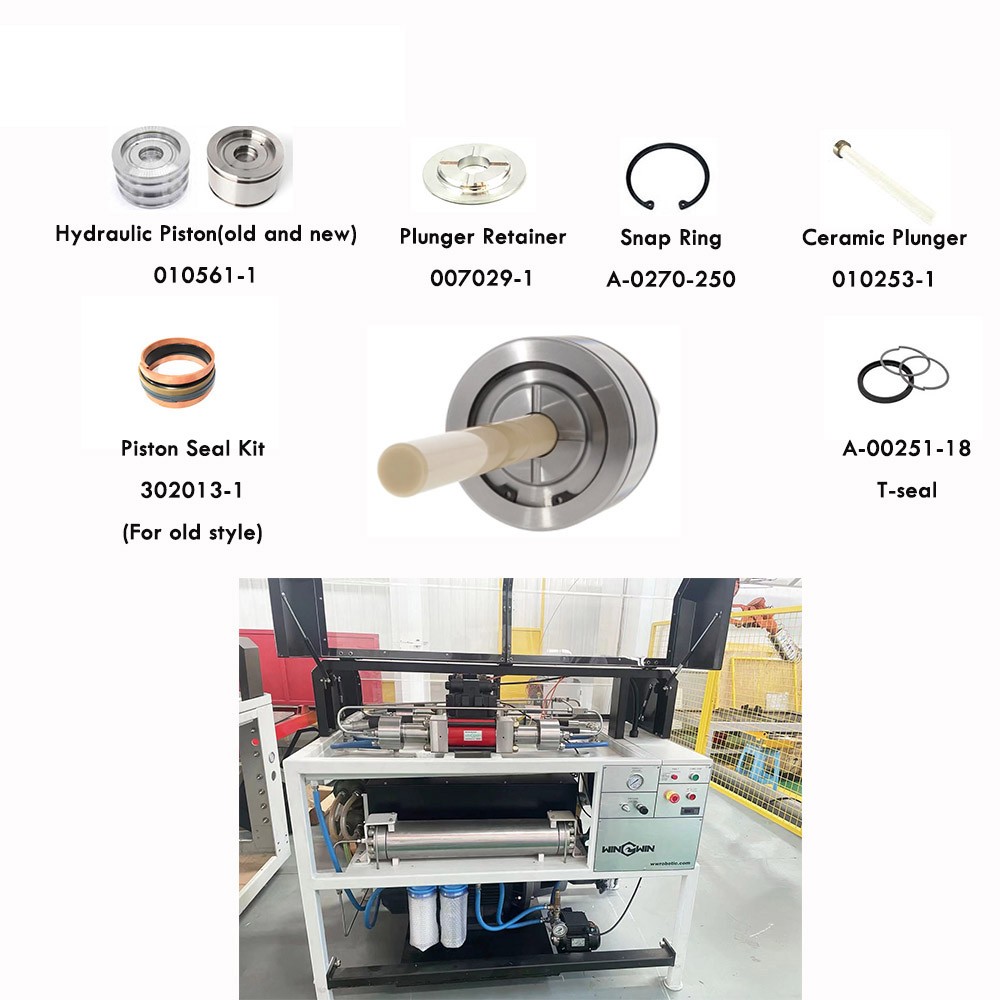

As a professional waterjet manufacturer,WIN-WIN has many waterjet cutting machine for sale which can meet your demand. In the same time,if you have any waterjet problems welcome to ask us. We are glad to fix your waterjet problems.

wwaterjet

wwaterjet