Development of water jet cutting

Since the introduction of water jet cutting technology in the 1990s, it has been popular in various fields, especially in the field of metal cutting and processing, with advantages that other cutting methods cannot compare. With the passage of time, not only has the technology of water jet undergone significant development, but their application scope is also constantly expanding.

At present, CNC water jet with high quality waterjet accessories is more widely used in deep processing of cutting architectural ceramics, stone, glass, and medium precision processing of metal sheets. Compared to the initial water jet, CNC water jet can perforate most materials without replacing any cutting tools. However, abrasive waterjet cutting do not transmit heat or surface stress to stones or tiles, allowing the material to maintain its original appearance and strength.

With the promotion of such technology, water jet cutting with high quality waterjet accessories will also penetrate into a wider field, especially in the field of composite material processing, to meet the special characteristics of different material properties in each layer of composite materials. In short, the wide range of industry demand and adaptability to various materials determine the application prospects of the fixed ultra-high pressure water jet cutting technology with high quality waterjet accessories.

Water jet and precision carving

Water jet cutting can process materials, and precision carving is also one of the material processing techniques. What are the differences between these two technologies? The following is an understanding of the definitions of the two processes mentioned above, from which you can see the differences.

Water jet cutting with high quality waterjet accessories is mainly used for material processing, without excessive limitations on material performance. Therefore, water jet cutting is currently a highly applicable cutting process method. It has many advantages, such as not generating heat during cutting; No further processing is required and has already been processed. Capable of cutting and drilling any curve. Having high-quality cutting quality and so on.

And precision carving is suitable for processing small tools, with high machining accuracy and relatively low torque. Due to its emphasis on carving function, the corresponding materials are usually low hardness plates, which are not suitable for large workpieces with strong cutting. In summary, the difference between water jet and precision carving lies in the former's function being cutting, while the latter's function is carving.

Water jet for processing sheet metal

Although traditional cutting equipment can also complete the processing of sheet metal, the effect is always not as ideal. However, if waterjet cutting with high quality waterjet accessories are used, they can demonstrate significant advantages in terms of cutting efficiency and precision, which are directly related to the characteristics of waterjet.

Due to the real-time control of the jet by the water jet, energy utilization can be achieved to minimize energy waste. Due to the fact that waterjet with high quality waterjet accessories can reduce the occurrence of errors, many parts can be directly processed through water jet, greatly simplifying the process.

If it were a regular device, there might be many restrictions and requirements on materials, while there are no such concerns with waterjet and waterjet accessories, indicating that their application range is very wide.

Water jet for cutting steel pipes and rods

There is a great demand for cutting steel and building materials products in the market. In order to improve cutting efficiency and quality, waterjet with high quality waterjet accessories have been successfully applied in these fields. Can products such as steel pipes or rods also be cut with a water jet? What are the experts' explanations for this?

With the continuous improvement of water jet technology, its applicability has been continuously expanding, especially for mature metal materials, which can be said to be universal. Although steel pipes, bars, and other products are also considered steel products, they are an exception. Generally, only products with relatively small diameters can be cut with a water jet to achieve ideal cutting quality, and the premise is that the material must also rotate with the water jet during cutting.

The cutting requirements for steel bars are more stringent, requiring the use of three-axis linkage to complete, and it also incurs higher cutting costs. From this, it can be seen that steel pipes and rods cannot be cut with a waterjet, but there are many limitations, and water knives are not their optimal cutting method.

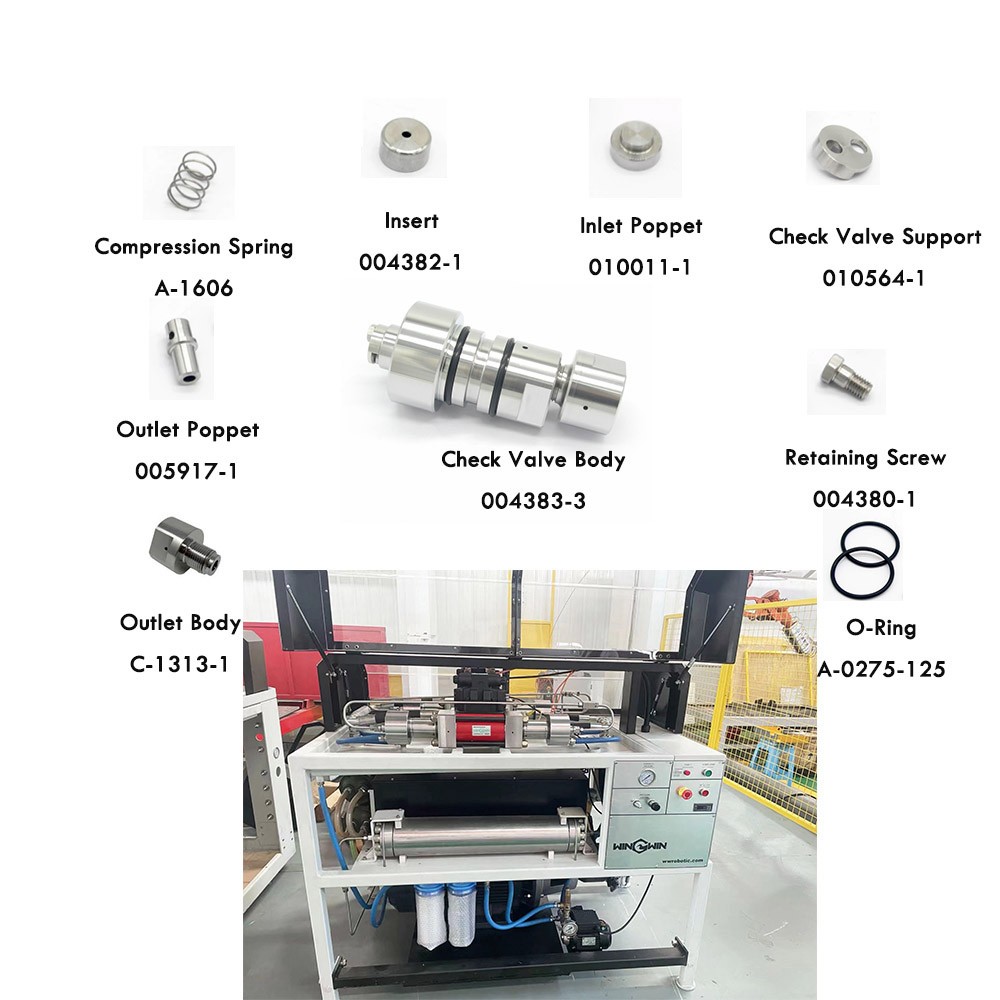

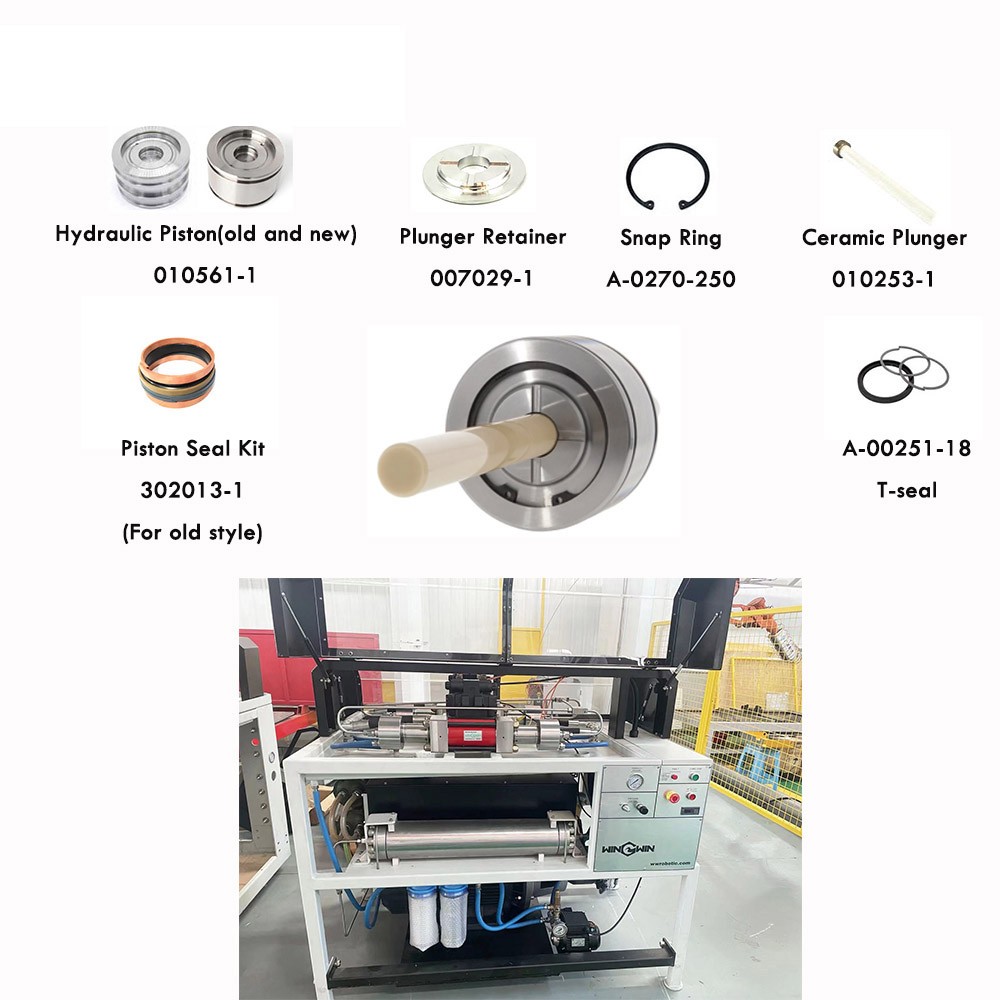

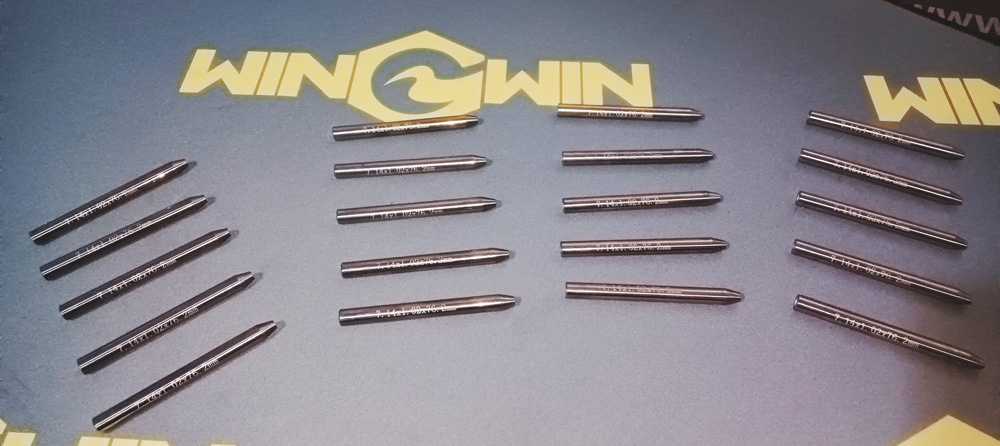

Waterjet accessories for water jet cutting machines

In addition to core components,waterjet accessories also have a significant impact on the cutting effect of ultra-high pressure water jet cutting machines, and there are many types of waterjet accessories, each with different functions, and no one can do without them. Below are some accessory products for ultra-high pressure water jet cutting machines, hoping that everyone can master them.

In the ultra-high pressure water jet cutting machine, the source of high pressure is the high-pressure intensifier, which can provide great pressure for the water jet cutting process, so that water can excite super large pressure through the waterjet accessories nozzle, which can instantly cut objects. The waterjet accessories that has a type effect is a waterjet accessories HP tube. The high-pressure intensifier is a variable pressure device, and the use of waterjet accessories HP tube is to allow the pressure to travel and eventually release from the nozzle.

During the use of the equipment, malfunctions are inevitable, and timely repairs are not necessary to have a significant impact. At this point, the waterjet accessories repair kit can play a good role. The waterjet accessories of the ultra-high pressure water jet cutting machine also include alloy pistons, which mainly play a blocking role, effectively blocking the water source in the hose and avoiding bending of the hose.

wwaterjet

wwaterjet