Basic issues related to water jet cutting machine

Water jet is a device specifically designed for cutting processes, which can be applied to most metal or non-metallic materials. Since the professionalism of water jet with good waterjet accessories is so strong, most consumers have limited understanding of it, and further analysis is needed to achieve a comprehensive understanding.

Water jet cutting accuracy issues

Starting from the cutting accuracy of the water jet with high quality waterjet accessories, the cutting accuracy of the water jet cutting machine is+/-0.1mm. If a dynamic water jet cutting machine is used, it can also help eliminate the cutting slope and further improve the cutting accuracy. Next, there are limitations to the cutting thickness of the water jet, even if its ability is strong. Generally, the water jet can cut any material with a thickness of 0-50mm.

The cutting seam cut by a water jet is approximately 10% larger than the diameter of the cutting tube, typically between 0.8mm and 1.2mm. What we often see is that water jet cutting machines use waterjet accessories garnet as an abrasive, but to ensure its quality, high-quality waterjet accessories garnet abrasive is reddish brown, free of dust and impurities, and the particle edges are also sharp and angular.

Quality issues with waterjet accessories abrasive

Since the advantages of water cutting have been well-known to most people, it has become a very common processing method. However, as a comprehensive whole, it requires the reasonable coordination of various components to achieve good results. Of course, this also includes the quality of waterjet accessories abrasive, which directly affects the effectiveness of water jet cutting, and many corresponding negative performances also arise as a result.

For example, when the waterjet accessories abrasive is not clean, it will cause the sand pipe of the waterjet to be blocked, thereby reducing the output power; When the hardness of the waterjet accessories abrasive does not meet the standard requirements, not only will the power decrease, but its cutting effect will also be affected, which will greatly increase the cost from a cost perspective.

Waterjet accessories abrasive is segmented sand, and the cutting speed and cutting surface can be smooth only when the corresponding particle size segment is maintained. If the particle size concentration ratio of waterjet accessories abrasive is not good, there will be uneven particles, either forming a sand pipe plug or failing to achieve the understood cutting effect. In short, it will affect the entire cutting process.

Design Issues of waterjet accessories sealing

Water jet is a special equipment that uses water as the power and carrier to perform cutting. With the continuous promotion of water jet cutting machine and the continuous improvement of water jet technology, a lot of customers are paying attention not only to the cutting ability of the water jet, but also water jet durability. Considering the characteristics of the water jet, in order to withstand the ultra-high pressure impact of water, the waterjet accessories sealing problem of the equipment is crucial.

For the sealing performance of water jet, the viscosity of the medium directly affects it. In general, the lower the viscosity, the better the fluidity, and the greater the difficulty of sealing. Also, when processing objects with different hardness, the higher the hardness, the higher the pressure, and the higher waterjet accessories sealing requirements. Therefore, the sealing design of water jet should consider the comprehensive influence of these factors.At present, there are many options for waterjet accessories sealing, but no matter which type of sealing is chosen, as long as it can achieve high-performance sealing, it is suitable. This way, the water jet can be used longer and safer.

Many times, it takes skill to do a good job, just like in water jet cutting, the skills gained through experience can help us complete the cutting process more efficiently and accurately. For example, although the cutting speed of smaller sand particles is relatively slow, their surface is smoother.

If the object of the task is composite material, glass or stone perforation, it is necessary to ensure that the system can use a controller to reduce or increase water pressure when using a water knife; At the same time, it is necessary to inspect vacuum assisted devices or other technologies to increase the probability of successful perforation of these brittle or laminated materials;

Another point to remind everyone is that before injecting tap water into the waterjet system with high quality waterjet accessories, impurities in the water are usually filtered out through the water filtration system, as it has been proven that softening the water can further improve cutting quality.

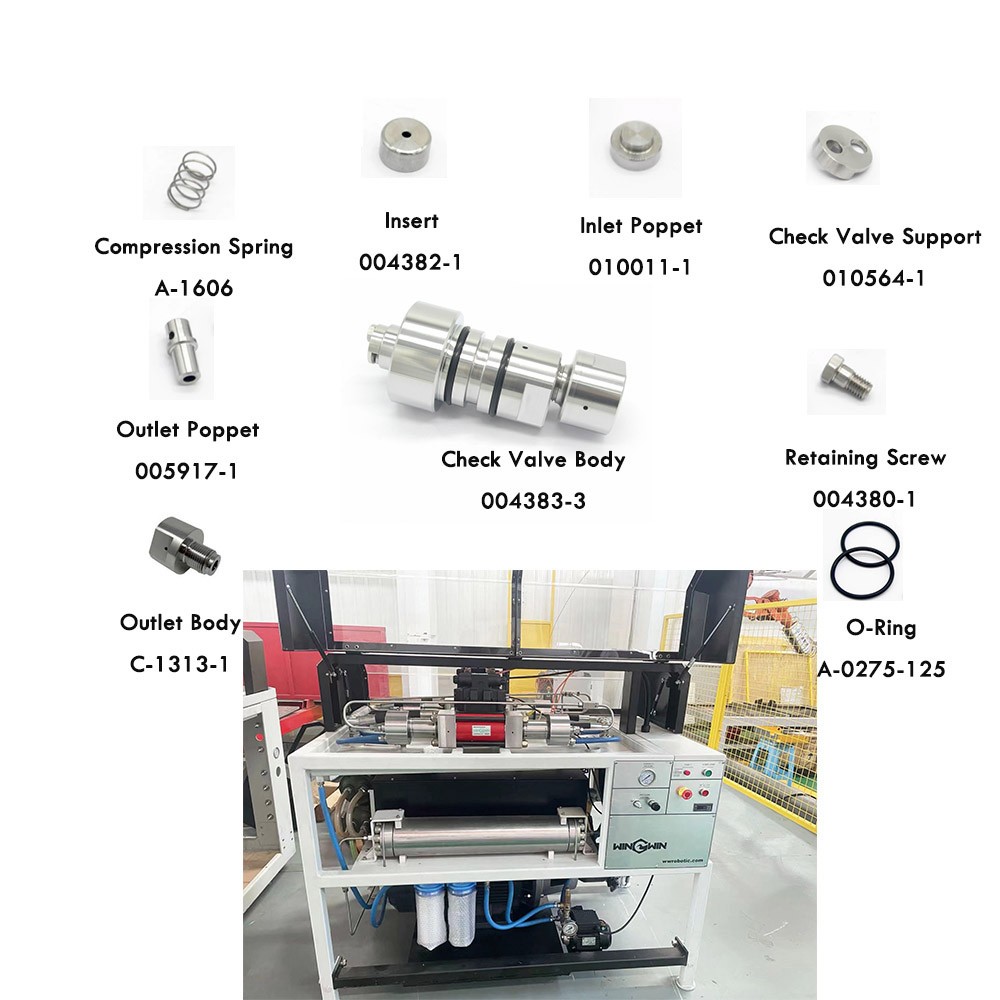

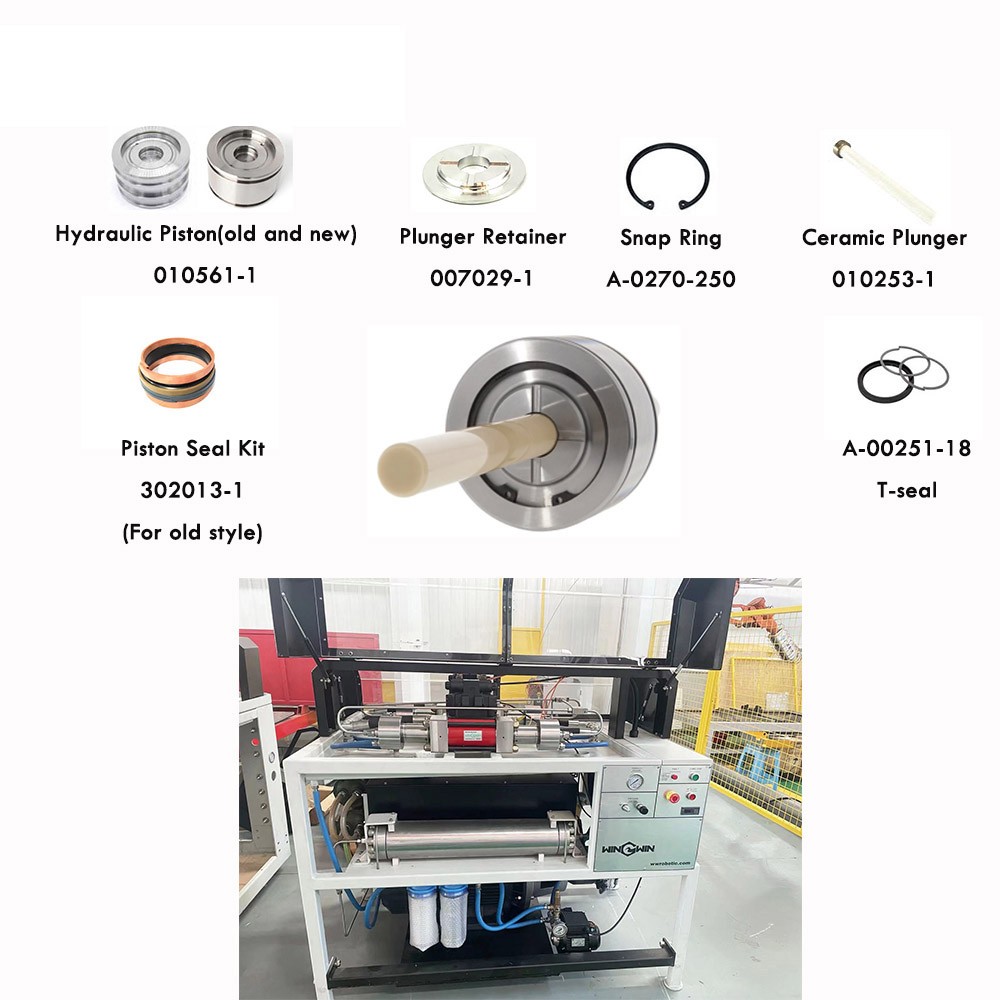

For the accuracy of your water jet cutting machine,please choosing high-quality waterjet accessories The high-quality waterjet accessories produced by WIN-WIN can fully meet your needs, while also extending the service life and cutting accuracy of the water jet cutting machine.

wwaterjet

wwaterjet