Water jet cutting technology(waterjet cutting machine and waterjet spare parts) provides users with unique functions and advantages of cutting methods. In the process of cost reduction, engineers, R & D and manufacturing departments always need to find new advantages. After in-depth understanding of water jet technology and waterjet spare parts, you will have the opportunity to take advantage of these cost-saving cutting equipment.

What is a waterjet

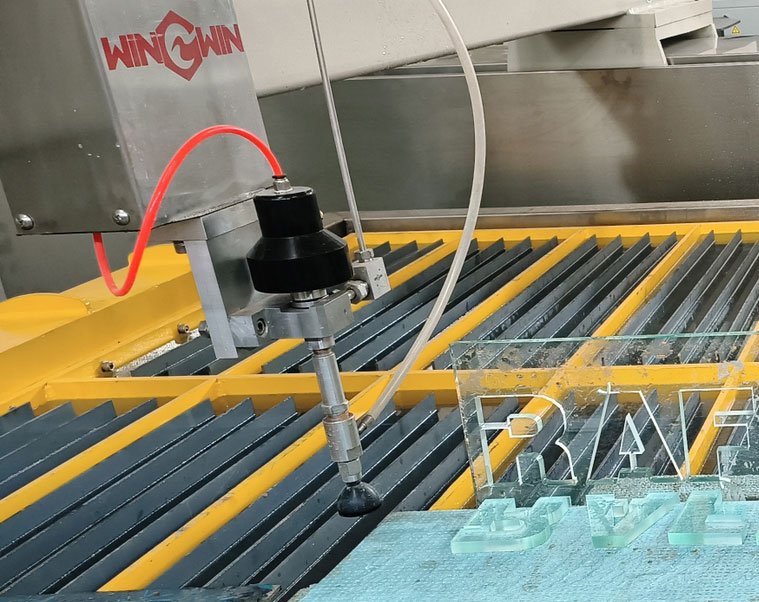

In addition to low-cost cutting, water jet cutting is also considered to be the processing technology with the most diverse functions and the fastest technological growth in the world, that is, the universal cutting machine (according to the report of Frost & Sullivan and market intelligence research). Water jet cutting machines and waterjet spare parts are widely used in high-yield applications all over the world. It complements other technologies (milling machine, laser, EDM, plasma and planer). Water jet cutting does not use toxic gas or liquid, and will not produce toxic substances or steam. The water jet cutting surface shall not leave any HAZ or mechanical deformation. It is a real multi-functional and high-efficiency cold cutting technology. The water jet has proved that it can complete the work that cannot be handled by other technologies. From cutting extremely thin details on stone, glass and metal, rapidly drilling holes in titanium alloy, cutting food, to sterilizing beverages and solutions, the water jet has proved its unique value.

Water jet and waterjet spare parts can be divided into pure water and abrasive cutting. Using pure water jet can cut all kinds of non-metallic materials: such as paper, cloth, diapers, glass fiber, food and all kinds of fluffy materials without wetting them; After adding abrasive, abrasive water jet can also cut all kinds of brittle and hard materials: such as stainless steel, aluminum, copper, all kinds of marble, metal, all kinds of glass except tempered glass, plastic products, ceramic technology, composite materials and all kinds of hard materials.

Cutting quality of water jet

The cutting shape and dimensional accuracy of water jet are mainly affected by the accuracy of nozzle trajectory and the diameter of nozzle inner hole. After using the CNC numerical control system, it is worth noting that the motion accuracy of the nozzle can be strictly controlled, and the dimensional accuracy of the workpiece can be controlled within ± o.1mm. It depends on the quality of waterjet spare parts.

It is worth noting that the slit width is related to the diameter of the inner hole of the nozzle. The smaller the diameter, the higher the machining accuracy. In fact, the slit width is about 0.025mm larger than the diameter of the nozzle. In addition, adding additives to water can improve the cutting performance and reduce the cutting seam width.

The cutting quality is greatly affected by the material properties and the quality of waterjet spare parts. Soft materials can obtain smooth surfaces. Good plastic materials can cut high-quality edges. If the water pressure is too low, the trimming quality will be reduced, especially for composite materials. In fact, it is easy to cause material delamination or scaling. When using abrasive high-pressure water to cut large thickness workpiece, the section quality changes with the cutting depth. Within 1o - 50mm near the upper part of the nozzle, the section is flat, smooth and of good quality; It is worth noting that there are shallow ripples in the middle transition region; In the lower part of the section, it is worth noting that due to the diffusion of abrasive water jet, the cutting energy is reduced and deep curved ripples are formed.

The cutting size is accurate and there is no dust pollution. In fact, it changes the monotonous and rigid ceramic floor tiles in the past, presents colorful decorative effects, and makes the damaged ceramic floor tiles and stone leftovers appreciate dozens of times after deep processing.

Water jet cutting machine and waterjet spare parts, this cutting technology is a modern cutting technology with multi-purpose and perfect performance. Its biggest feature is the processing of high-pressure waterjet without heat source and the non thermal process in cutting, which can have incomparable advantages in many fields. It has the characteristics of no thermal deformation, flat incision, no dust and pollution, reducing material waste and so on. The function and use of water jet involves all aspects of production and life, which has brought great changes to our production and life. So waterjet spare parts are very important for the whole waterjet cutting system. It is the carrier of modern industrial application and the crystallization of scientific and technological modernization.

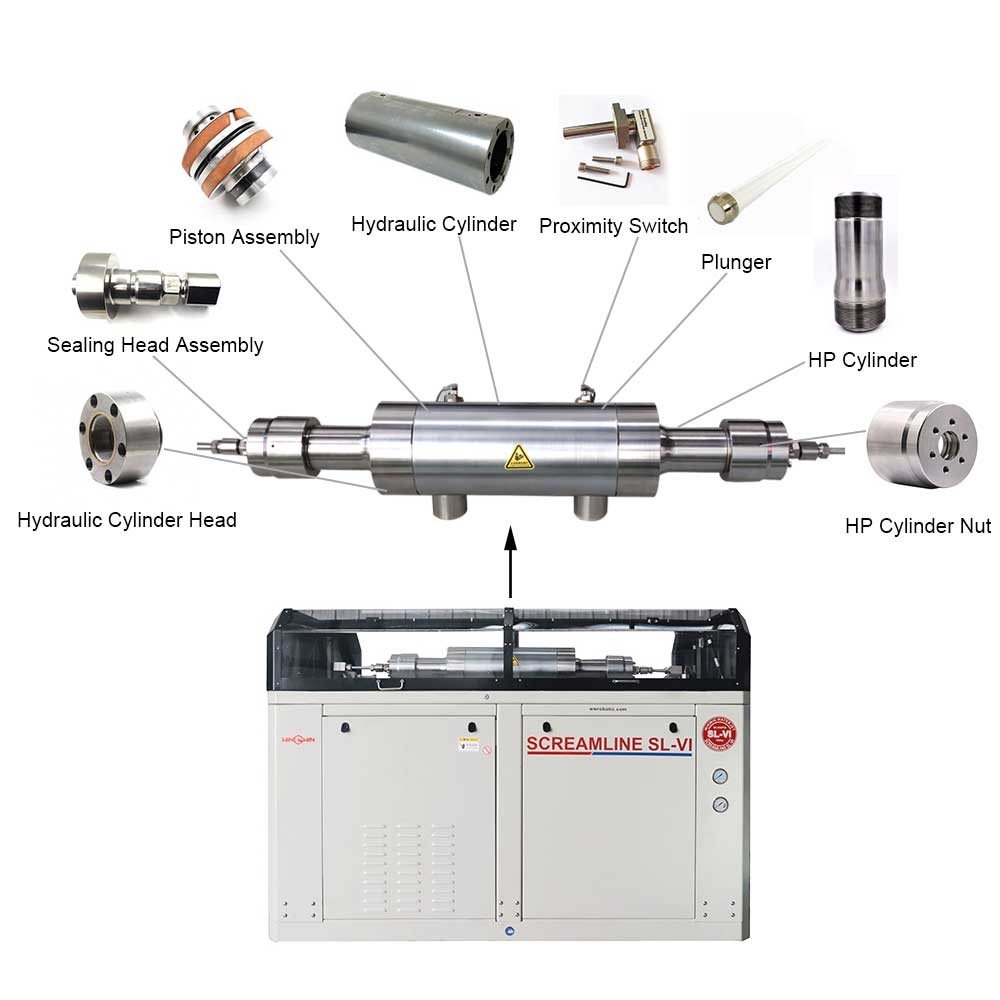

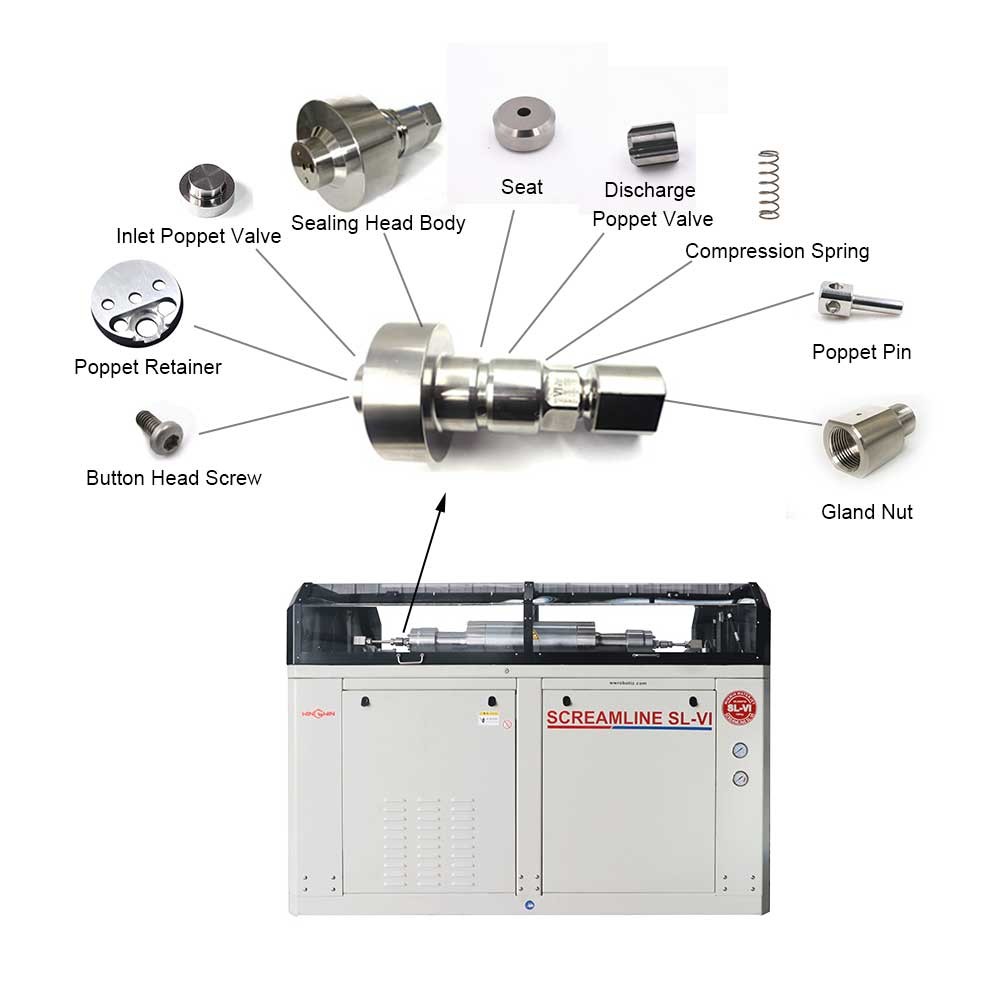

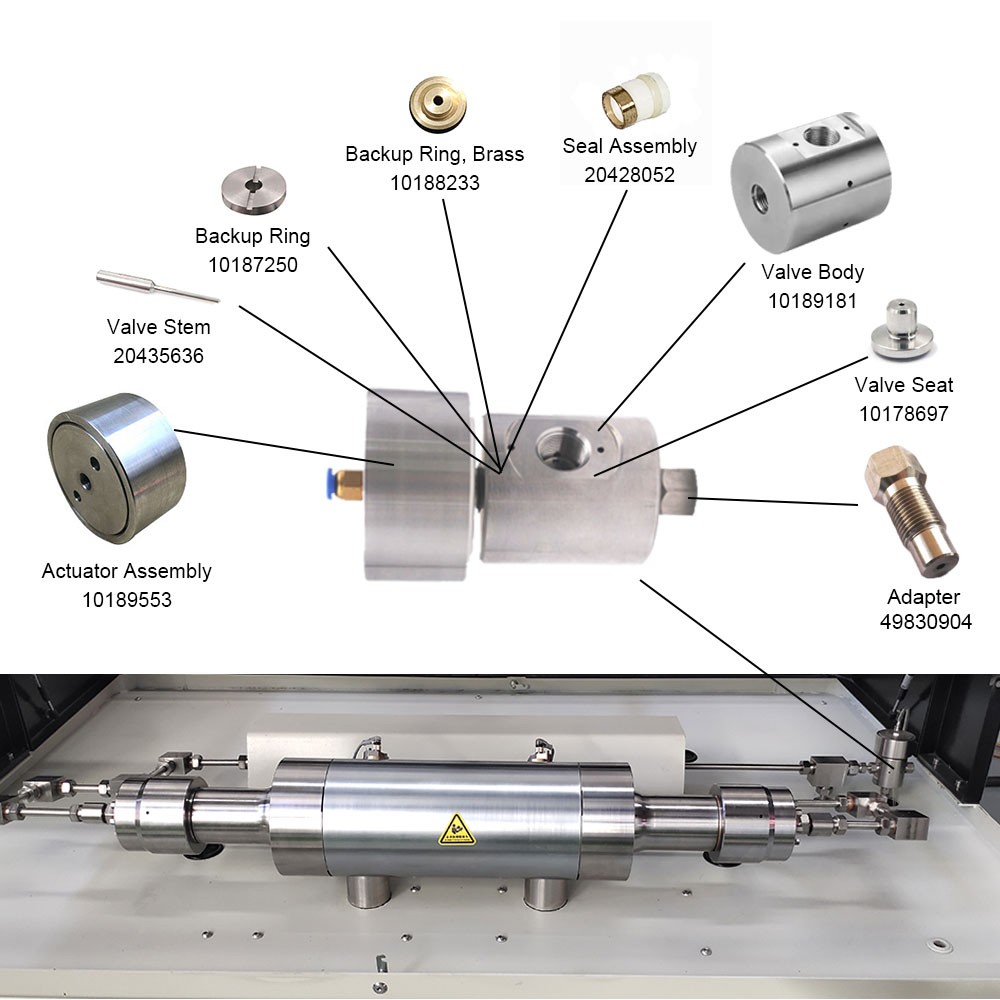

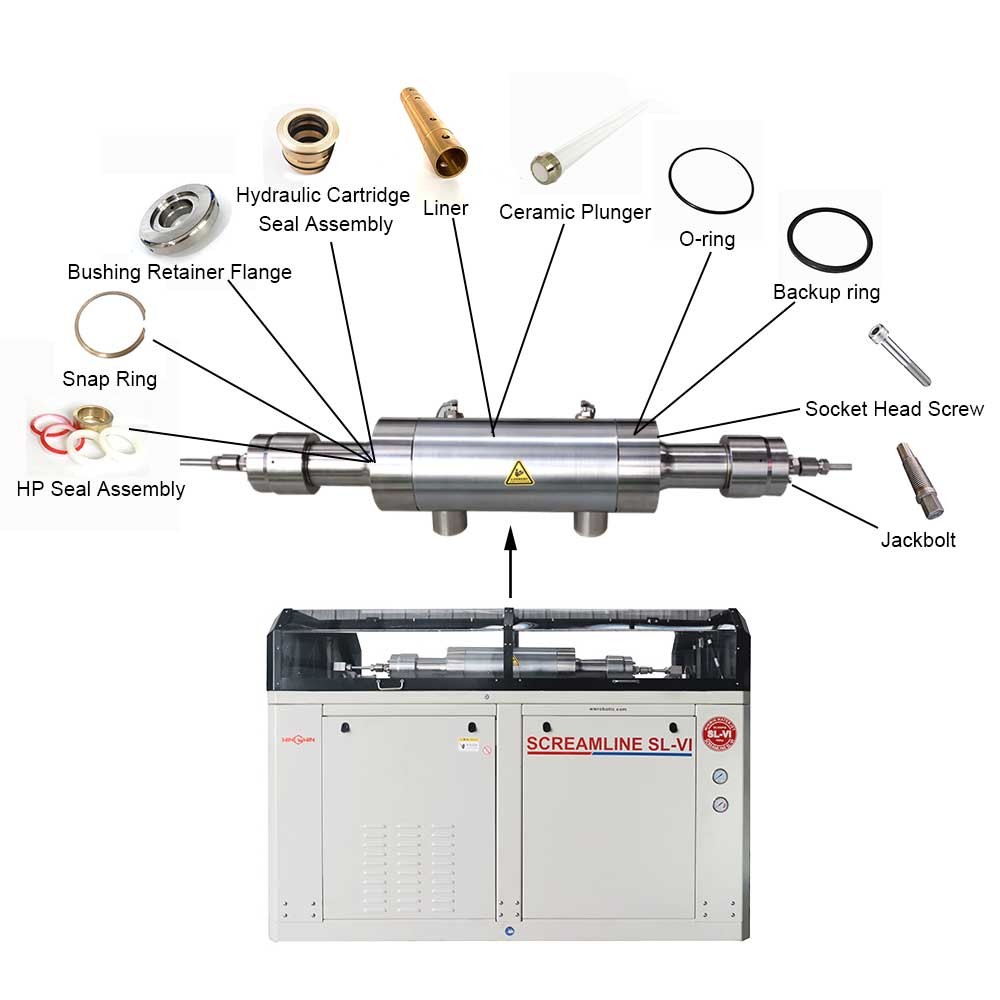

Win-Win is a company which can provide you with high quality waterjet spare parts t maintain your waterjet cutting machine. We have many waterjet spare parts that you can pick for your waterjet cutting machine.

wwaterjet

wwaterjet