The advantage of pedestal type and ceiling type robot waterjet cutting machine

Pedestal type

The robot is installed on the base in an upright way, and the worktable is fixed on both sides of the base. The robot can cut in two stations alternately. While cutting in one station, it can load and unload in the other station. It is especially suitable for the cutting and processing of automotive interior trim parts such as vehicle ceiling and carpet with large size and high precision with waterjet spare parts.

Features

1. Open design, suitable for cutting vehicle carpet, ceiling and other parts with increased size and high precision

2. High cutting precision and good stability with waterjet spare parts

3. The lengthening arm robot is installed vertically and covers a wide range

4. Two robots can work together to improve production efficiency

5. Multi station design, feeding and cutting are carried out at the same time, with minimum downtime.

6. Different stations can cut the same or different workpieces at the same time

7. All round safety design ensures system operation and personal safety of operators

8. Through the change of robot installation position, the single robot four station or double robot three station system can be expanded arbitrarily to meet the different needs of users.

9. Integrated design, all functional components of the system are automated and easy to operate

Ceiling type

The robot is installed on the top of the cutting chamber upside down, and the worktable is divided into cutting area and loading and unloading area by the rotating wall. When the system is turned on, the workbench will automatically rotate 180 degrees to automatically transfer the products to be cut in the feeding area outside the cutting room to the cutting room for cutting; After cutting, the worktable automatically rotates 180 degrees in reverse to transfer the cut workpiece out of the cutting room to complete the blanking and loading operations, so as to realize the continuous cutting of two stations. It is especially suitable for cutting and processing automotive interior trim parts such as automotive carpet, automotive ceiling, instrument panel and door panel.

Features

1. Integrated design, suitable for cutting vehicle ceiling and other components with high precision by using waterjet spare parts

2. The upside down robot is installed with large coverage and fast running speed

3. Multiple robots can be used to work together to improve production efficiency

4. High cutting precision by using waterjet spare parts

5. Only one operator is needed in a single feeding area to reduce labor cost

6. All round safety design ensures system operation and personal safety of operators

Why can water jet cut steel?

This sounds incredible, but as long as the water flow is fast enough, it can be used to cut metal.The water jet can cut because the water flow is guided from a waterjet spare part nozzle inlaid with gemstones and ejected at very high pressure, so as to keep the water flow concentrated. Unlike metal knives, water knives never become dull or overheated. The waterjet spare part nozzle sprays a mixture of water and cutting sand at a speed of about 1448 km / h.

Water jet can be used to cut the following materials: marble, granite, stone, metal, plastic, wood and stainless steel. Water jets can cut "sandwiches" of different materials stacked about 15 cm thick. This tasteless, dust-free and relatively non heating process can also be used to cut things only about one thousandth of a centimeter thick. This one-time forming cutting process saves material cost and processing cost. For example, engineers only need to send a gear diagram to the cutting workshop with USB flash disk or e-mail, and then they can get the final processed gear.

The actual operation process is usually completed in the water jet cutting platform and waterjet spare parts, which can prevent splashing water and noise. By increasing the feed speed of the cut material, the water jet can be prevented from cutting through the material.Generally, the shaft head of five axis water jet cutter is divided into AB axis and AC axis. We commonly use AB axis.

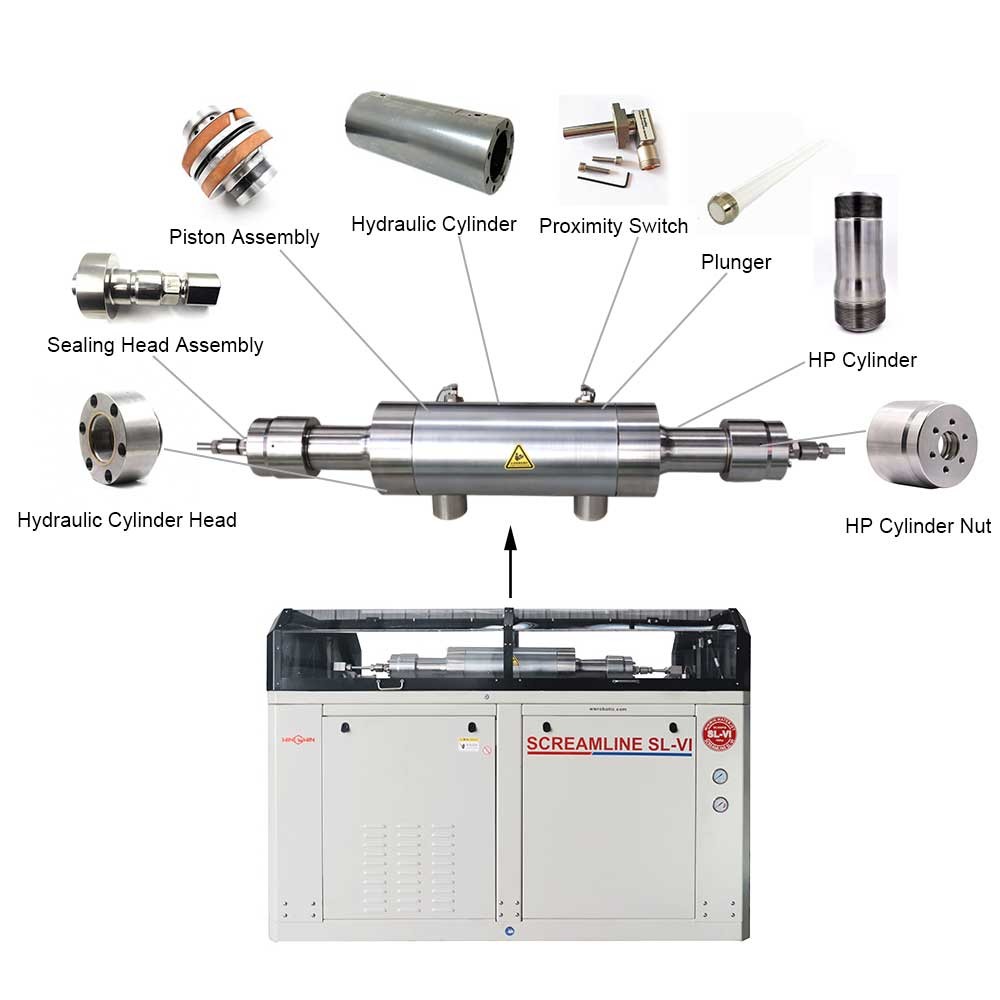

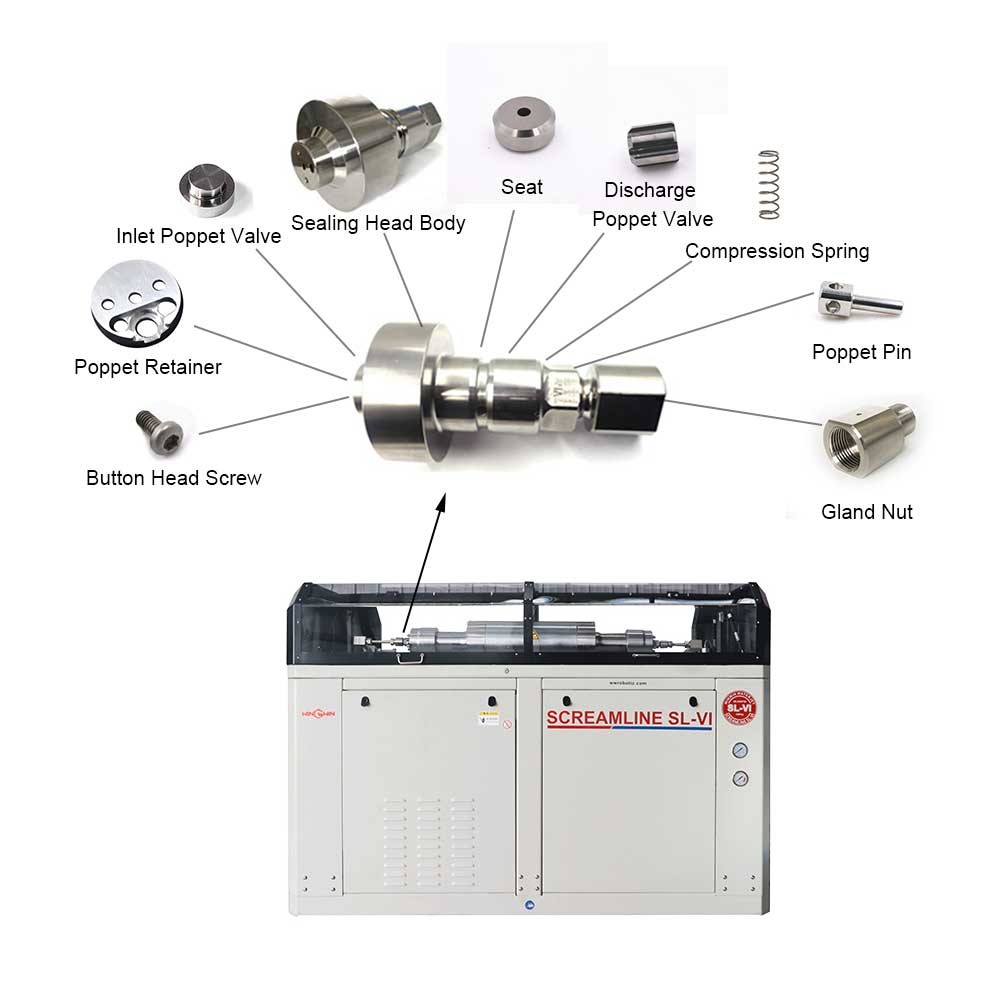

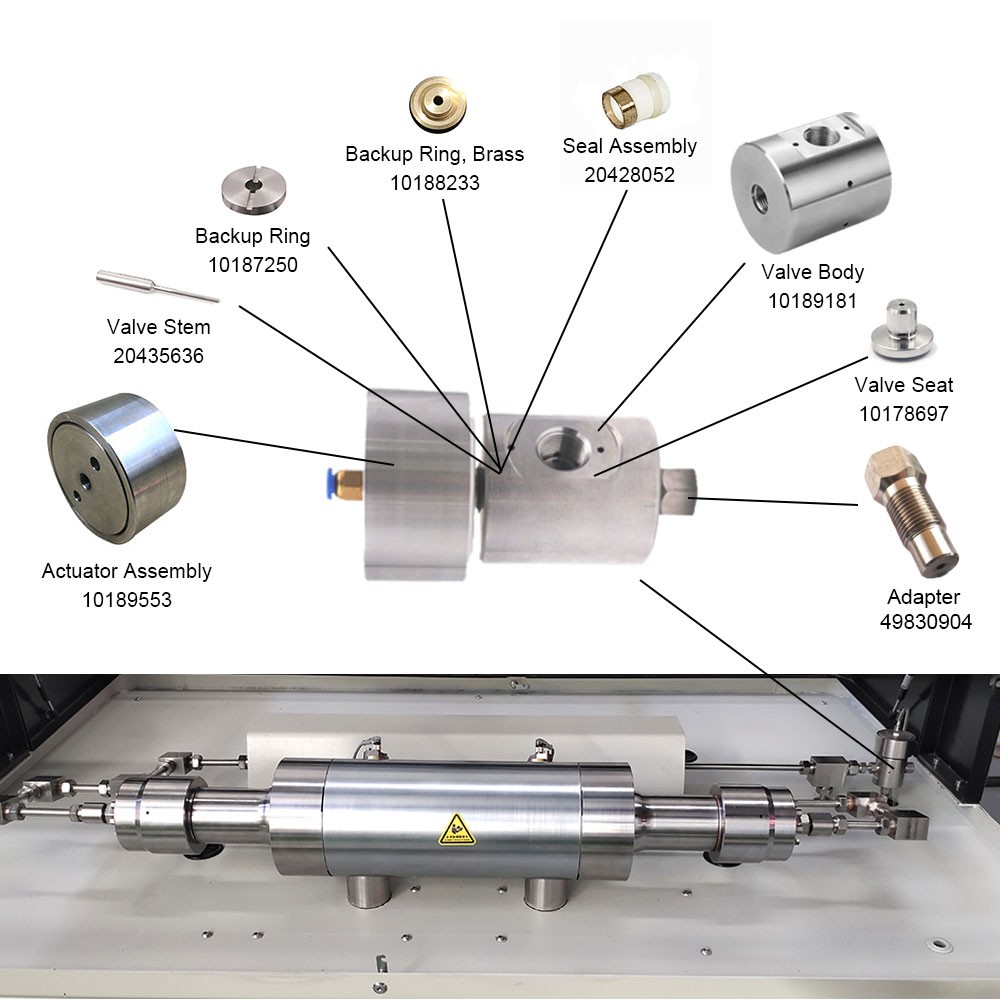

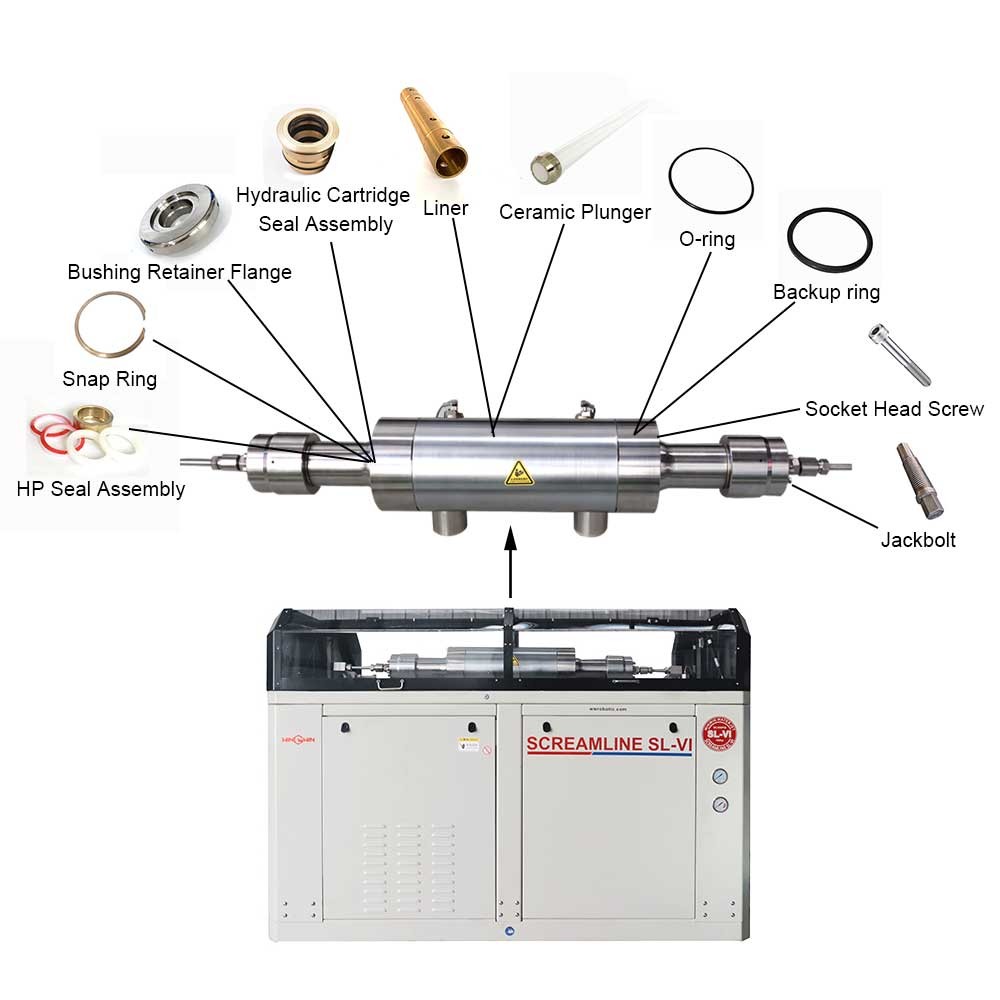

Waterjet spare part cutting head: it is a complete set of imported high-pressure water switch. All servo motors are imported servo. The five axis special harmonic reducer is more durable and waterproof.

Waterjet spare part HP parts: the energy accumulator is changed into a system, there will be no water leakage, and the damage of end cap nuts will be eliminated.

Waterjet spare part HP tubes: all high-pressure tubes adopt imported high-quality high-pressure pipes.

Water jet cutter system: the five axis operating system is simpler, especially for drawing. After drawing CAD drawings, the program can be generated. It doesn't need to be generated from other software before.

wwaterjet

wwaterjet