What is a water jet cutting machine

Gantry waterjet and cantilever water jet cutting machine

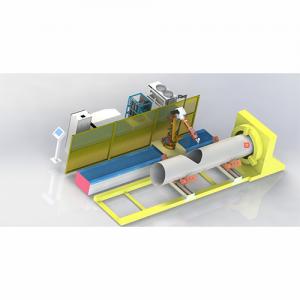

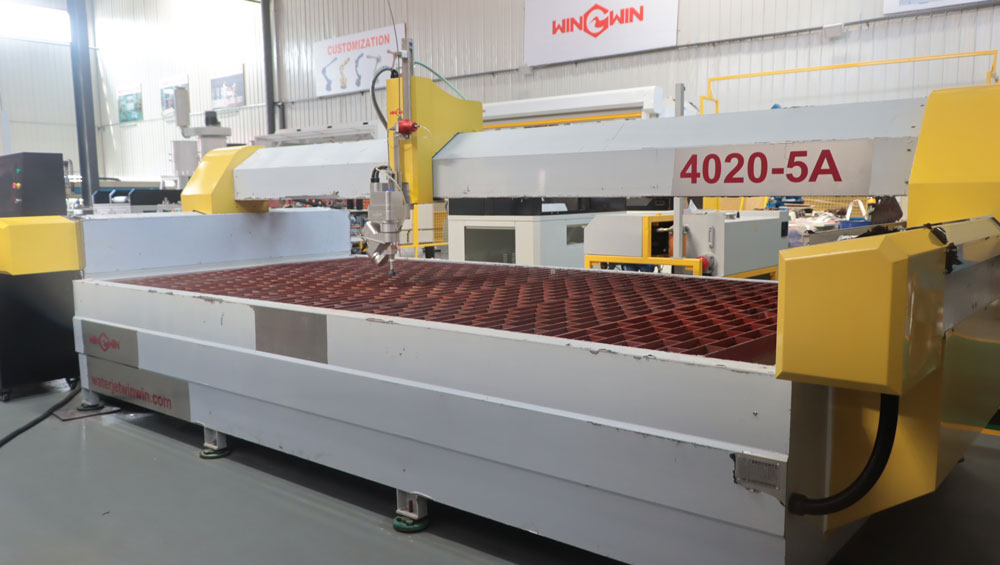

It is already very difficult to decide to choose a waterjet among many cutting equipment, but now it is even more troublesome to determine the specific model of the water jet cutting machine. There are many types of water jet, and their performances are also different. Which one to use depends on the actual situation. Regardless of these for the time being, let’s first distinguish between the two types of gantry water jet and cantilever water jet.

The gantry water jet cutting machine is a one-piece structure. Because its cutting arm is supported at both ends, it has certain stability and is not easy to tilt. In this way, even if it is used for a long time, cutting errors are not easy to occur. But some irregular workpieces are not easy to place, and the price is relatively high.

The cantilever water jet cutting machine is a split device, and its cutting arm track and cutting platform are separated, so the placement of the workpiece to be cut is very simple. If any part is damaged and needs to be replaced, it only needs to be replaced locally, and the cost is greatly saved. In terms of stability, it is not as ideal as the gantry waterjet, and it is difficult to keep the cut workpieces consistent.

The water jet cutting machine has been fully used in the cutting industry, and the user's response to the processing effect of the equipment is also very good, which is entirely due to the excellence of the equipment in all aspects. In order to meet different cutting requirements, the basic configuration of the water jet machine will also be different. How can we get a suitable water jet machine under the premise of fully considering various factors?

The configuration of the water jet cutting machine includes many parts, the main body of which is the operating platform, which is generally determined by the size of the actual cutting material. Cantilever type and gantry type are more commonly used. Platforms with different structures have their own advantages, so it is necessary to choose the one that matches the actual situation.

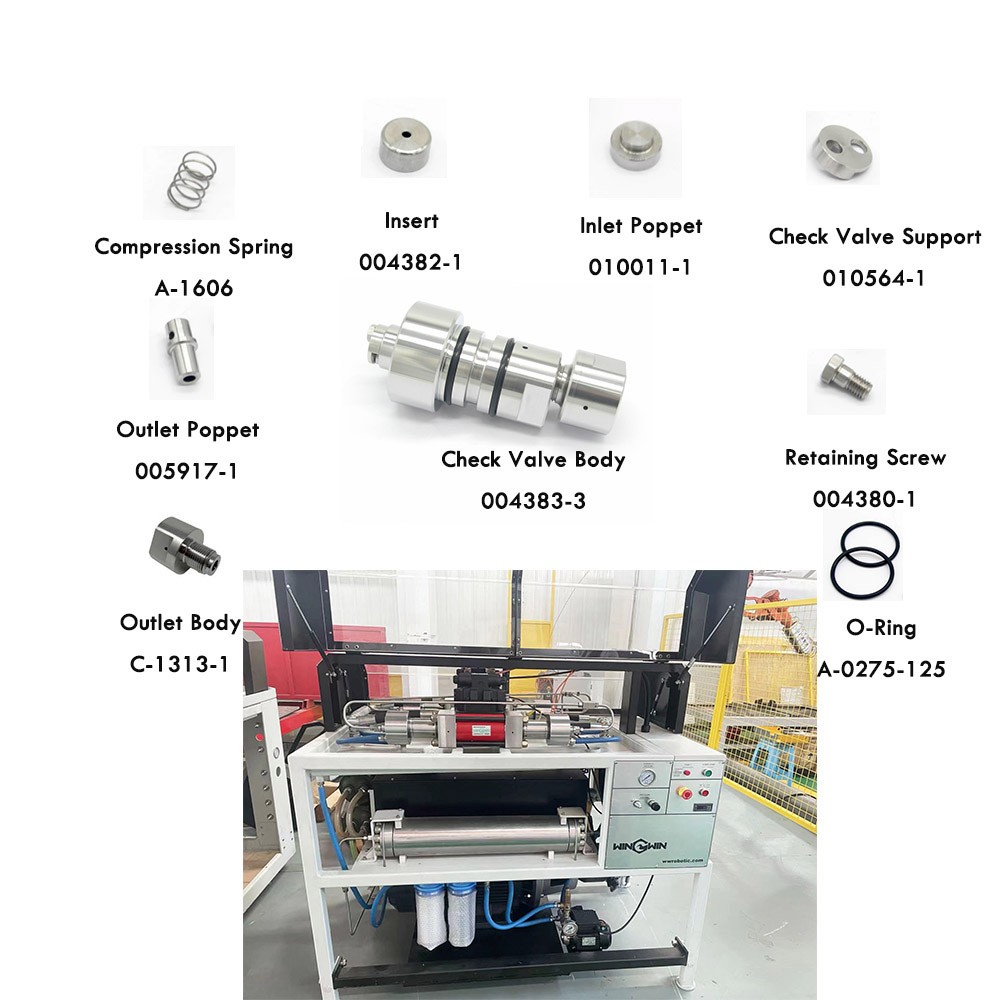

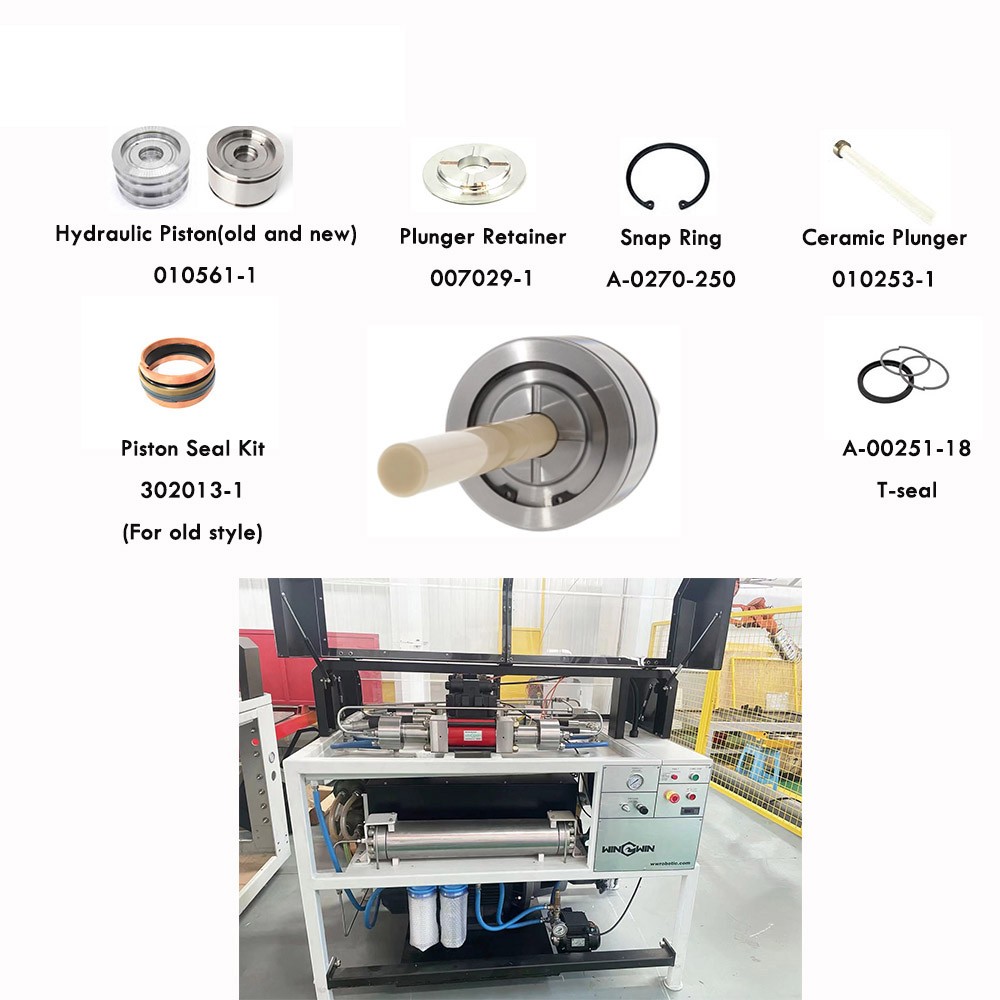

In addition to the working platform, the core component of the entire water jet cutting machine should be a high-pressure system, and the cutting ability exhibited under different pressures is different, so the selection should be based on the basic characteristics of the cutting material. Don't think that after these two aspects are determined, it is enough. There are other configurations that are equally important.

Water jet cutting machine is to use the effect of water jet to cut and break objects. In this new cutting process, water jet is the one that attracts attention.When the equipment reaches a certain pressure, the water will flow out from the nozzle of the water jet cutting machine and shoot at the object at a super high speed, thus causing an impact on it. However, when the impact occurs, it will also cause a sudden change in the jet velocity, which will cause a sudden change in the internal pressure of the water droplet and the internal stress field of the contact point material, and cause damage to the object.

That is to say, in fact, the interaction between the water jet droplet and the object is mutual. When the droplet acts on the surface of the object, the jet can only remain flat in the stage, and once it touches the solid material, it will move freely radially. From this, it can be proved that the speed of the water jet basic object in the water cutting machine changes in an instant.

Questions about water jet cutting machine

How much noise does the waterjet cutting machine make when cutting?

In fact, no matter what kind of equipment it is, there will always be a certain amount of vibration and noise during operation. As long as it is within the normal range, there is no major problem, generally at 80-85dB. However, we found that if the sand tube on the equipment is farther away from the workpiece to be cut, the noise will be greater, so it is still necessary to take corresponding protective measures.

Are there any requirements for water in the water jet cutting machine?

There must be requirements. Although ordinary tap water can meet the operating requirements of the water jet cutting machine, in order to protect the service life of high-voltage components, calcium and magnesium ions in the water can still be removed.

Compared with other cutting methods, is waterjet cutting regarded as a green and environmental protection public welfare?

In fact, it can be considered so to a certain extent, because the consumables used by the water jet cutting machine are all natural materials, as long as the workpiece to be cut has no harmful performance, the waste water produced by cutting also meets the standard for direct discharge.

wwaterjet

wwaterjet