Industrial application of high pressure water jet cutting technology

The usage of water jet cutting machine can achieve a variety of operations, such as cutting, degumming, cleaning, drilling, trimming, slotting and the removal of surface materials of workpieces. The development of waterjet cutting withj high quality water jet spare parts and the continuous emergence of new materials put forward new requirements for the processing process. For example, some special materials are used in aviation manufacturing industry, such as titanium alloy, carbon fiber composite, reinforced plastic glass, etc. For high-strength and high hardness materials (such as titanium alloy), if laser cutting is used, because the laser cutting is carried out at high temperature, there will be a heat affected zone at the material notch, which is seriously harmful to the performance of the material. Therefore, the heat affected zone must be completely eliminated through grinding, which increases the processing process and reduces the production efficiency. For carbon fiber composites, when cutting at high speed with ordinary methods, it is easy to produce winding on the tool. At present, the water jet technology by using good water jet spare parts used in industry mainly has two implementation methods: pure water jet and abrasive water jet.

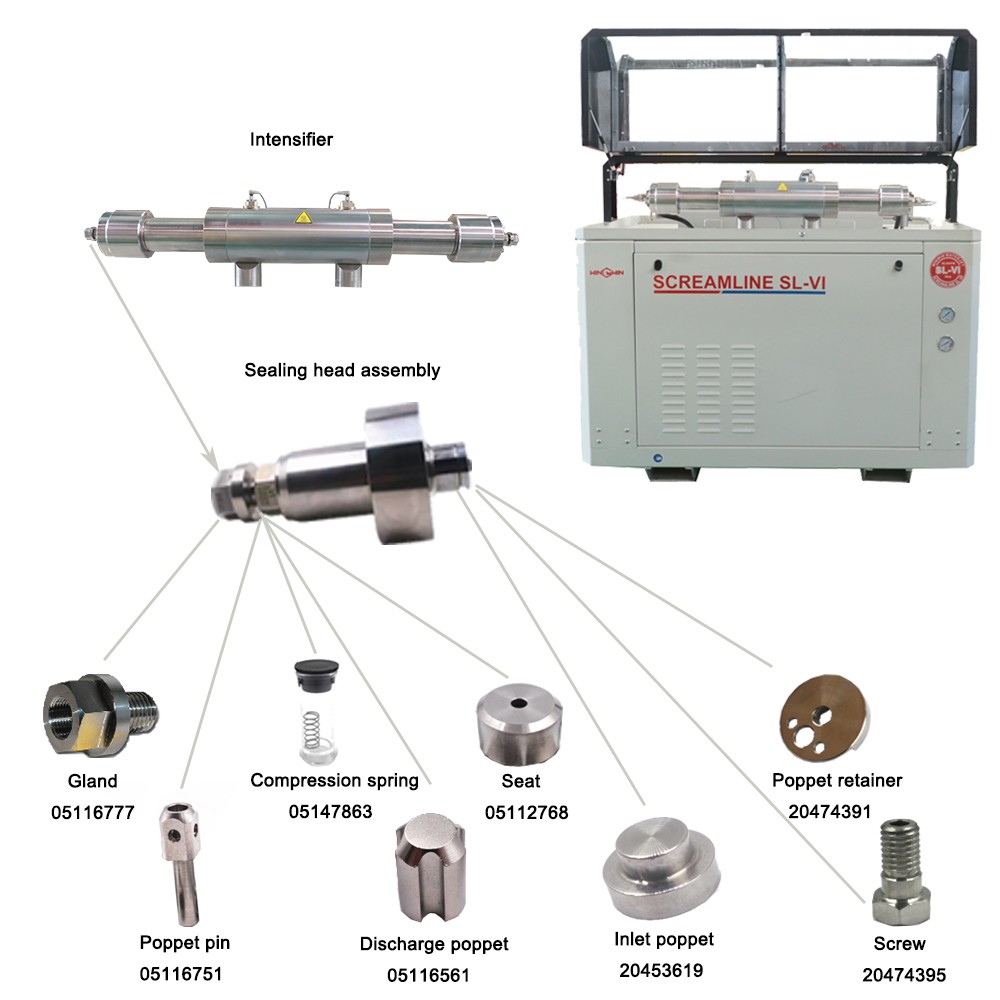

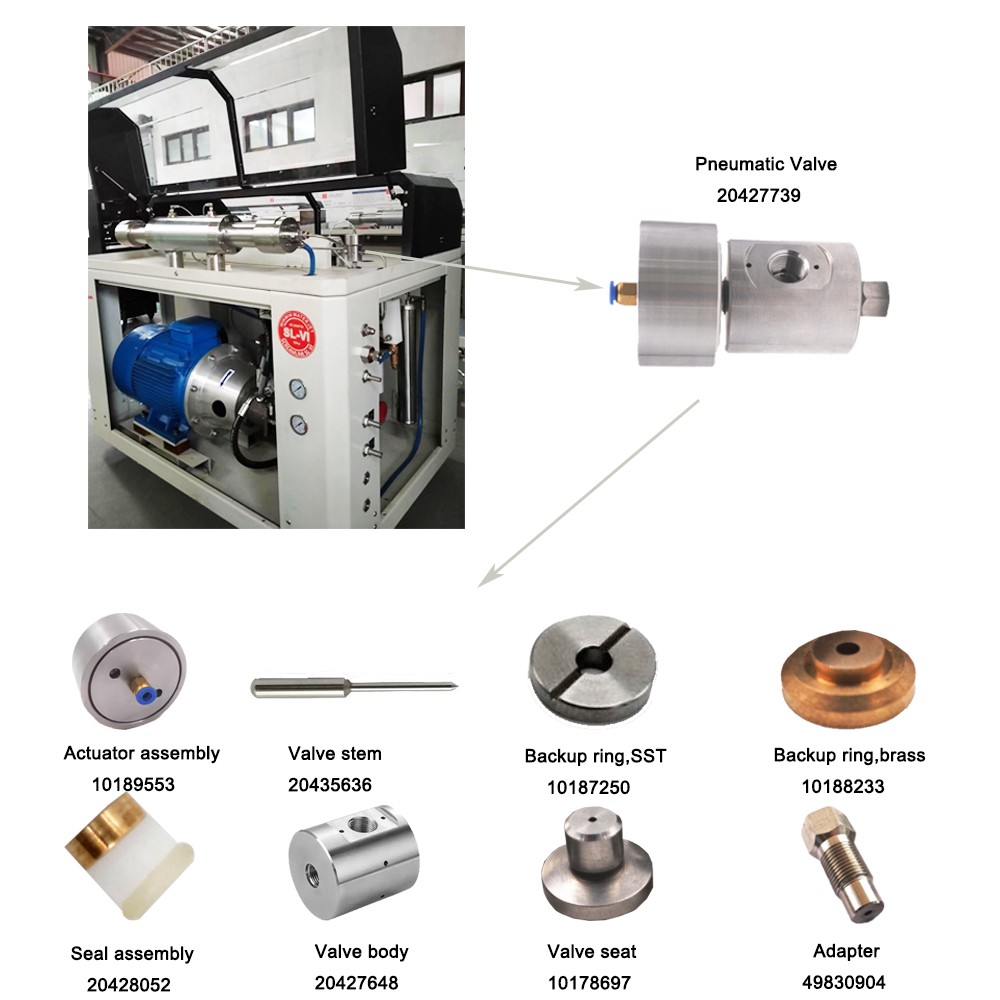

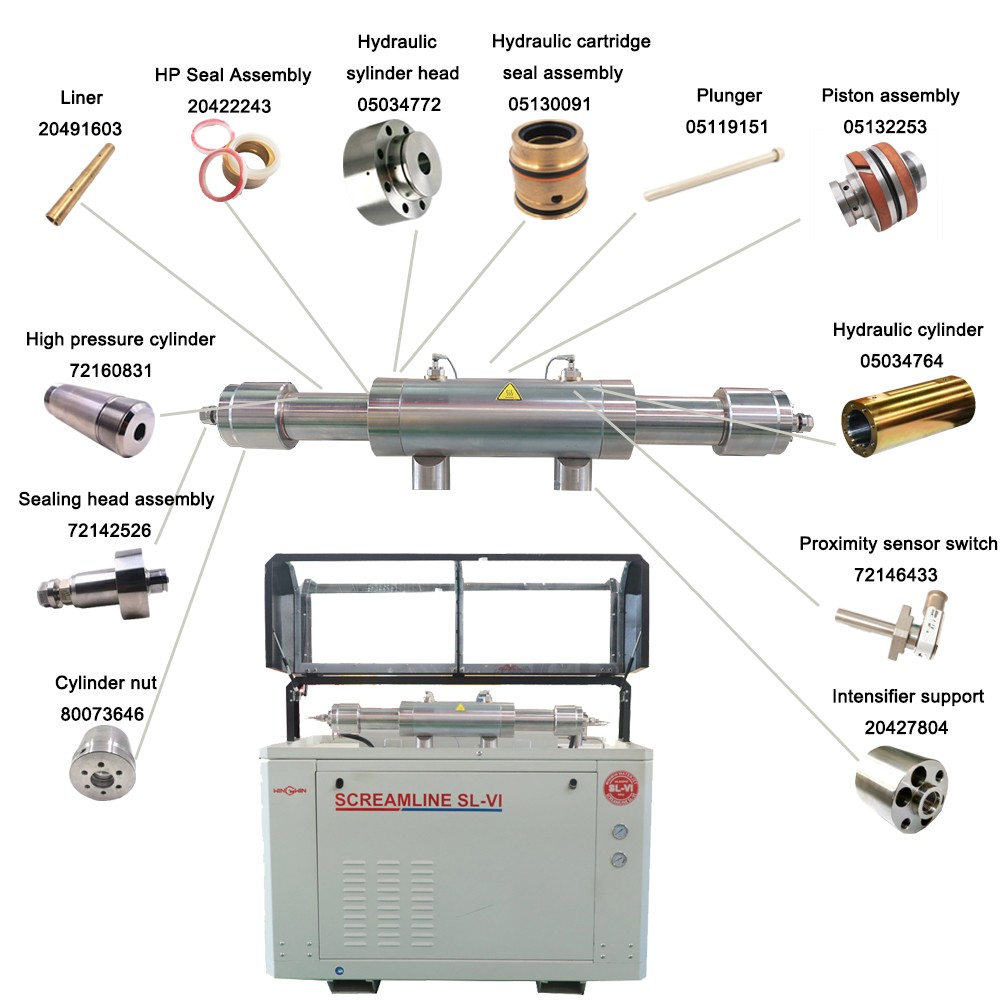

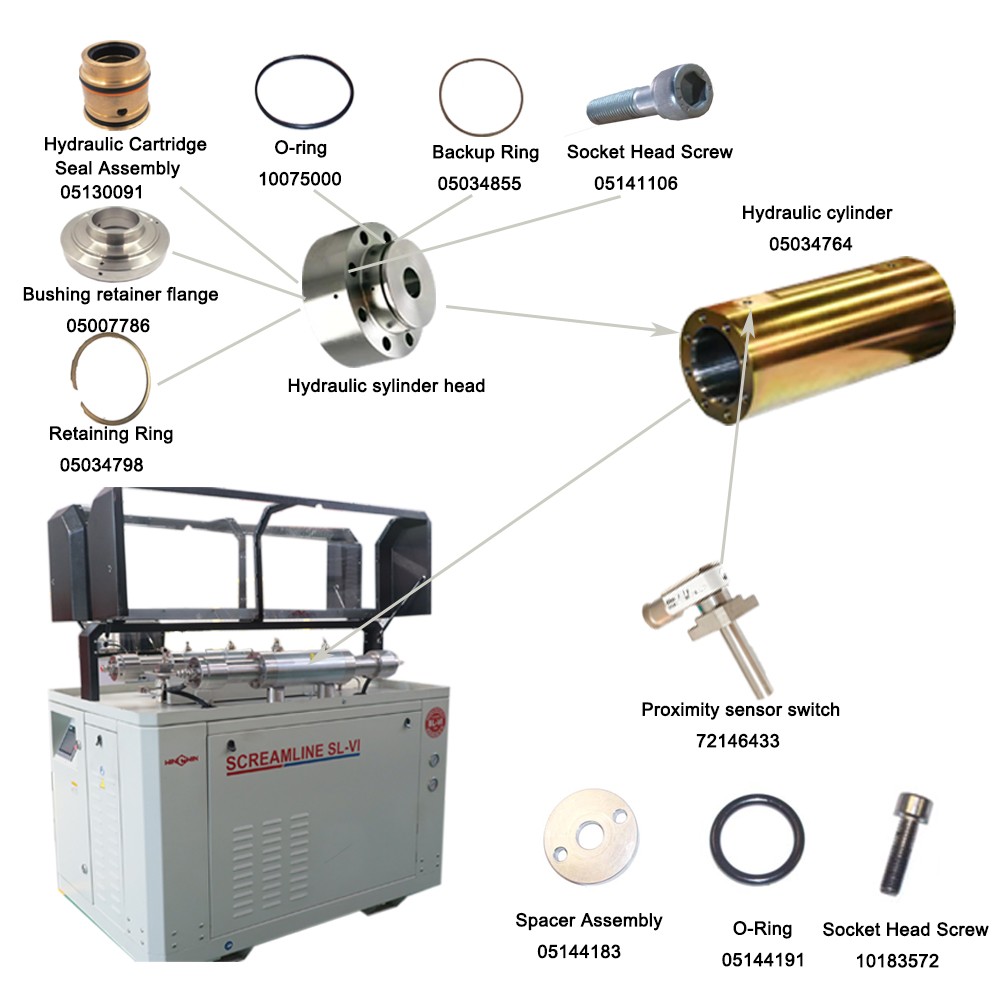

In the past 20 years, pure water jet has been widely used and laid the foundation for abrasive water jet technology. Pure water jet can be used for cleaning and deburring. When the water pressure is above 100MPa, soft materials such as plastics, paper and textiles can be cut. However, for the cutting of hard materials, the force of high-pressure water emitted by the nozzle is not enough. The abrasive is injected into the water flow between the high-pressure intensifier pump and the water jet spare part nozzle. With the addition of abrasive, the water jet has the characteristics of saw blade, and the force of water jet is greatly strengthened.

Water jet can cut almost any material, such as glass, metal, alloy, ceramic material and carbonized metal. In recent years, the application of high-pressure water jet cutting machine with water jet spare parts has achieved great development. In foreign countries, water jet cutting is also used as a revolutionary tool in surgery. Abrasive water jet cutting machine commonly used in industry includes abrasive injection cutting and abrasive suspension cutting, that is, what we usually call pre mixed abrasive cutting and post mixed abrasive cutting. The essential difference between the two methods is that the abrasive is added to the water in different ways, and the abrasive suspension cutting technology can provide better cutting effect. Another method called polymer water jet is to add a small amount of polymer long-chain polymer additives to the water to improve the jet density and range. It is mainly used to cut soft or slightly hard materials by using WIN-WIN water jet spare parts.

Automobile industry: processing all kinds of non-metallic materials, such as instrument panel, carpet, asbestos brake pad, door frame, roof glass, automobile interior trim panel, rubber, plastic, gas box, etc., as well as the forming and cutting of other internal and external components.

Aviation Industry: it can cut special materials, such as titanium alloy, honeycomb structure, carbon fiber composite, laminated metal or reinforced plastic glass, etc. For example, if the aircraft blade is cut with water jet, the cutting edge of the blade has no heat affected zone and work hardening phenomenon, and the subsequent processing is omitted.

Foundry industry: the foundry can use water jet cutting with gauranteed water jet spare parts to remove the alumina outside the workpiece, molding sand and ceramic coating on the casting. At the same time, gray iron castings that are difficult to cut by conventional methods can be cut. In the electronics and computer industry, the shape of printed circuit board and film can be formed and cut. Other industrial water jet and abrasive waterjet cutting with high quality water jet spare parts can also be applied in other industrial processing, such as cutting marble, granite and ceramics in the construction industry, processing finished paper rolls, corrugated paper and toilet paper in the paper industry, and processing plywood and wood boards in the wood industry.

Water jet cutting with pure water

This method is mainly used for soft materials, such as plastics, textiles, paper, sealing materials, metal foil, plywood, food, etc. Ordinary tap water is pressurized and forced through a water jet spare part orifice to produce a powerful cutting jet. The water comes out of the orifice at a speed of up to three times the sound and can be used to cut materials at a high cutting speed (determined by the characteristics of the material).

Abrasive waterjet cutting

Abrasive cutting methods are used for hard materials such as metals, glass, minerals, concrete, glass composites, ceramics, aluminum or silicon oxide. In other words, abrasives are added where pure water cannot cut the material correctly. The abrasive is added to the water jet during the cutting process. In the water jet spare part cutting head, water, air and abrasive are mixed together and forced to pass through the water jet spare part focusing tube at high speed. The generated high-energy water can be slightly corroded, that is, drilling and cutting, forming materials with large thickness and the highest density, such as metals, ceramics, rocks and even bulletproof glass.

wwaterjet

wwaterjet