WaterJet Part 20422243 High Pressure Seal Assembly

Transmission part of water jet cutting platform

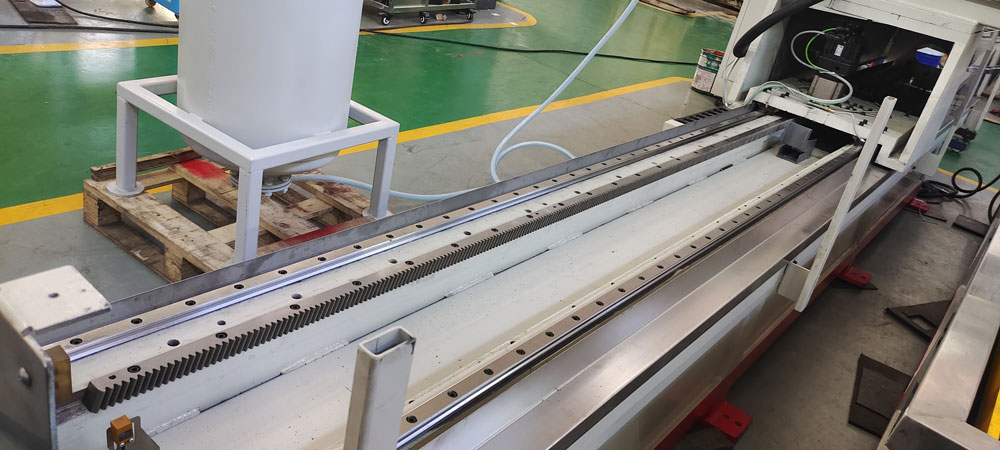

The transmission part of the water jet cutting platform includes x-axis, Y-axis and z-axis transmission parts. The following takes the gantry cutting platform as an example to illustrate its structure and working principle.

Working process of x-axis transmission part

When the water jet spare part servo driver drives the motor to rotate, the synchronous wheel installed on the motor will rotate to drive the synchronous belt and idler gear to rotate the nut nut on the screw rod Since both the water jet spare part screw nut and the slider are fixed on the connecting frame, the connecting frame moves steadily along the x-axis linear guide rail The friction coefficient of the bearing installed in the nut and nut support is very small, so the travel resistance after loading on the connecting frame is also very small.

The x-axis transmission part is installed in the aluminum beam. A side support is respectively installed at both ends of the aluminum beam, the side support is fixed on the side support transition frame, and the y-axis drive motor is installed on the side support transition frame. The y-axis water jet spare part drive motor is installed and connected with the idler gear on the y-axis ball screw through the synchronous wheel and synchronous belt; The inner side of the side support transition frame is installed and fixed with the two sliding blocks on the y-axis linear guide rail, so that the side supports at both ends of the aluminum beam are firmly fixed on the plane perpendicular to the y-axis linear guide rail. When the water jet spare part servo motors on both sides of the y-axis (one on each side) rotate synchronously, the side support is driven to make the aluminum beam move steadily along the y-axis direction.

Working process of y-axis transmission part

When the water jet spare part servo driver drives the motor to rotate, the synchronous wheel installed on the motor will rotate to drive the synchronous belt and idler gear to rotate the nut nut on the screw rod Since both the screw nut and the sliding block are fixed on the side support transition frame, and the side support is fixed with the side support transition frame, the side support moves steadily along the y-axis water jet spare part linear guide rail A bearing is installed between the nut and the nut support, and the friction coefficient is very small, so the travel resistance after loading on the side support is also very small.

Working process of z-axis transmission part

When the driver drives the stepping motor to rotate, make the driving wheel installed on the motor rotate the z-axis screw rod through the synchronous belt. Since the z-axis screw nut and guide column are assembled into one and connected to the sliding block through the connecting bending plate, the cutter head frame moves up and down along the direction of linear guide rail A bearing is installed between the z-axis screw rod and the z-axis outer frame, and the friction coefficient is very small, so the travel resistance is also very small after loading on the water jet spare part cutter head frame.

An XZ connecting frame is installed on the x-axis aluminum beam. The four sliding blocks on the x-axis linear guide rail (two linear guide rails in total, and two sliding blocks are installed on each linear guide rail) and the nut support are fixed at the bottom of the XZ connecting frame, and an X-axis servo motor is installed on the connecting frame. When the x-axis servo motor rotates, the connecting frame moves steadily on the x-axis linear guide rail through the rotation of the synchronous belt and synchronous wheel. Since the z-axis is installed and fixed at the front of the connecting frame, it also drives the z-axis transmission part to move steadily along the x-axis direction.

Other parts of the overall mechanical structure of the water jet cutting platform

The water tank of the overall mechanical structure of the NC cutting platform is mainly composed of welded water tank, along grid strip adjustment frame, along grid strip, etc.

The adjusting frame along the grid bar is used to adjust the plane levelness of the grid bar, and top screws are installed on its side and top surfaces. A drain valve is installed on the rear side of the water tank.

After the water in the water tank reaches the specified water level, the main function is to place the materials to be processed, and to receive the high-pressure water and water jet spare part abrasive discharged by the cutting machine, recover the leftover materials from the cut corners, reduce the pollution to the environment and achieve the effect of environmental protection.

The cutting water jet spare part is mainly composed of water jet spare part cutting head, water switch,water jet spare part high-pressure tube, sand storage container, manual regulating valve and vacuum pressure gauge.

If you are interesting in other SL-VI 50HP waterjet part,Contact us any time!

wwaterjet

wwaterjet