Suggestions of waterjet abrasive garnet

Water jet manufacturers said that water jet abrasive garnet is one of the main water jet spare parts for water jet operation, and only under its action can water jet complete the cutting of various workpieces. It is understood that the processing technology of water jet abrasive is not complicated, and the products are divided into different grades. Users must not only choose correctly, but also pay attention to cost control.

1. Waterjet manufacturers introduce the processing technology of waterjet abrasive garnet

The raw material of water jet spare part abrasive is 85.4% garnet rock ore, which is artificially dried to make the moisture content lower than the corresponding standard. After drying, the raw materials are mechanically crushed, and undergo a series of processes such as pickling, water washing, and drying. Finally, the secondary screening process is used to select the water jet spare part abrasive garnet that meets the requirements.

2. Waterjet manufacturers classify waterjet abrasive products

At present, 80-mesh water jet spare part abrasive garnet are mostly used in water jet, which can perform perfectly in terms of cutting speed and cutting accuracy. In addition, there is also 120-mesh waterjet abrasive garnet, which is generally used in precision cutting, such as glass cutting. Waterjet abrasive garnet, can be divided into five grades according to the quality of the cutting surface. Different grades of water jet spare part abrasive garnet are required for different requirements and conditions.

3.Tips for reducing water jet abrasive components recommended by water jet manufacturers

Although this material is widely distributed, the grades of raw materials are different, the procurement requirements are different, and the cost is also different. In order to reduce the cost of water jet sand, on the one hand, you can choose a processing company with high quality quartz sand products and a suitable quotation for processing, and appropriately reduce the processing cost of water jet spare part abrasive garnet.

On the other hand, we can start by reducing the cost of transportation, but no matter what, high-quality products are the key. In the process of purchasing water jet spare part abrasive garnet, this is the focus of attention.

What I recommend to everyone is RZG garnet waterjet abrasive, which has high hardness and scientific particle size distribution. It not only has a high cutting speed, but also has high cutting precision and excellent cutting quality.

Water jet have great pressure and a wide range of cutting materials

Water jet cutting is mature cutting equipment and cutting technology, which can play a very good role in cutting various products in various fields. This is inseparable from the characteristics of water jet cutting. There are almost no items around us that cannot be cut by water jet cutting.

1. The water jet is characterized by strong pressure

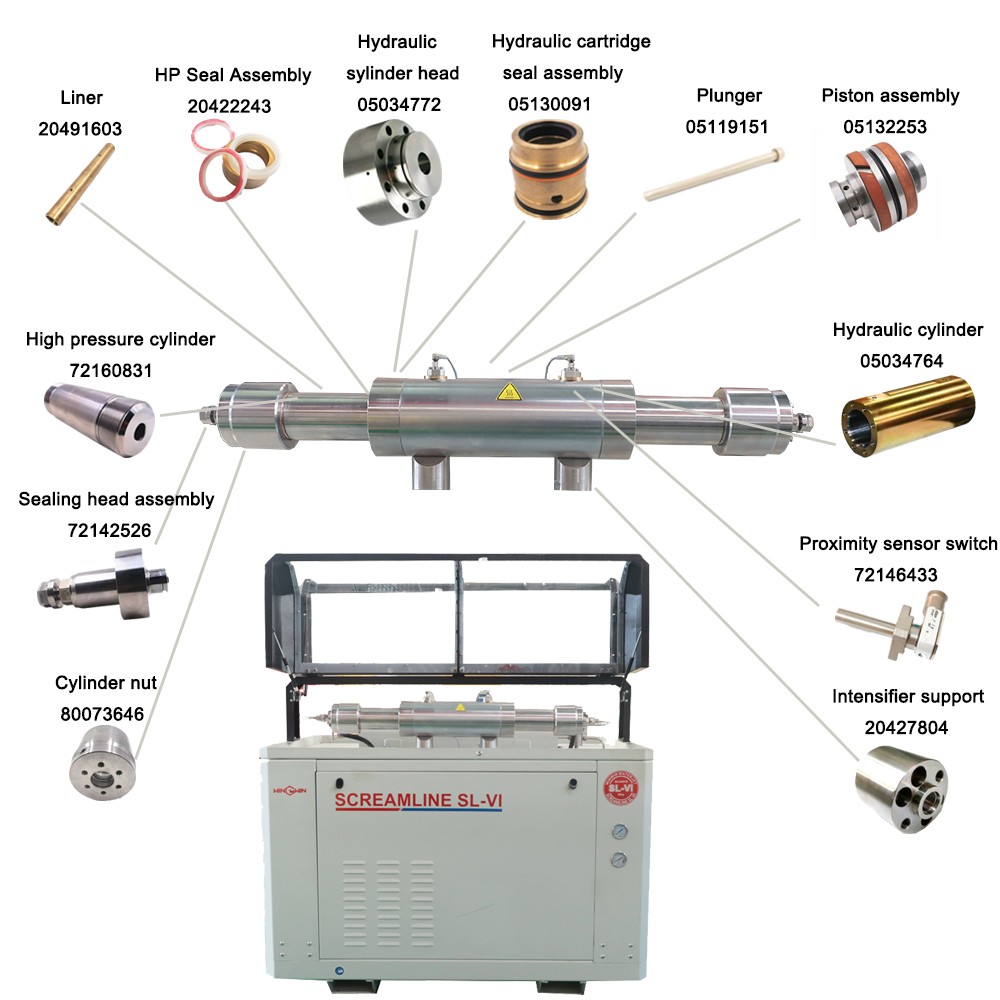

The water jet operation is inseparable from the effect of pressure. In order to generate strong pressure, the diameter of the water jet spare part diamond orifice is generally designed to be very small. Only in this way can it pressurize the water to a higher level through the ultra-high pressure intensifier.

After the water jet has a very high pressure, it must be sprayed through the very fine nozzle of the nozzle. This water jet spare part nozzle is usually made of carbide, sapphire, water jet spare part nozzle diamond and other materials in order to obtain a very fast speed. So the water jet can form a high-pressure water flow with extremely strong cutting ability.

2. Waterjet requirements for water, HP tubes

The purity of the water used in water jet is very high. Although it is not completely free of impurities, the content of impurities should be reduced as much as possible. The water jet spare part HP tube configured on the water jet needs to be able to withstand extremely high pressure, because the water jet must have high pressure to cut the material, and at the same time, the piping must also have such a bearing capacity.

3. Materials that can be cut quickly by using waterjet

Most materials are not a problem for water jet, even for all special materials, the cutting ability can be enhanced by adding abrasives such as sand to the water jet. Specifically, glass, rubber, fiber, fabric, steel, stone, plastic, various non-ferrous metals, composite materials, etc. can be applied. In other words, apart from diamond and tempered glass, there is almost nothing that a water jet cannot cut. So you should choose high quality water jet spare part. We are a professional water jet spare parts manufacturer that can provide you with many water jet spare part brands

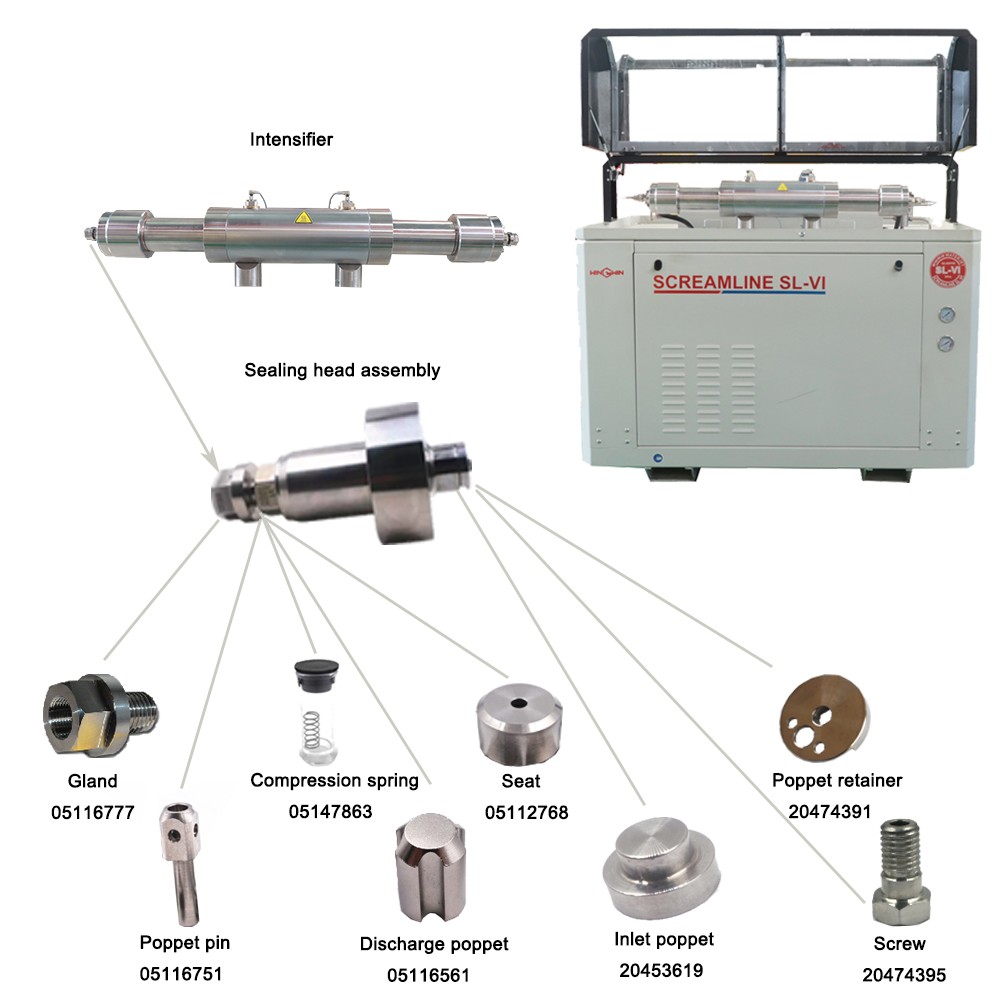

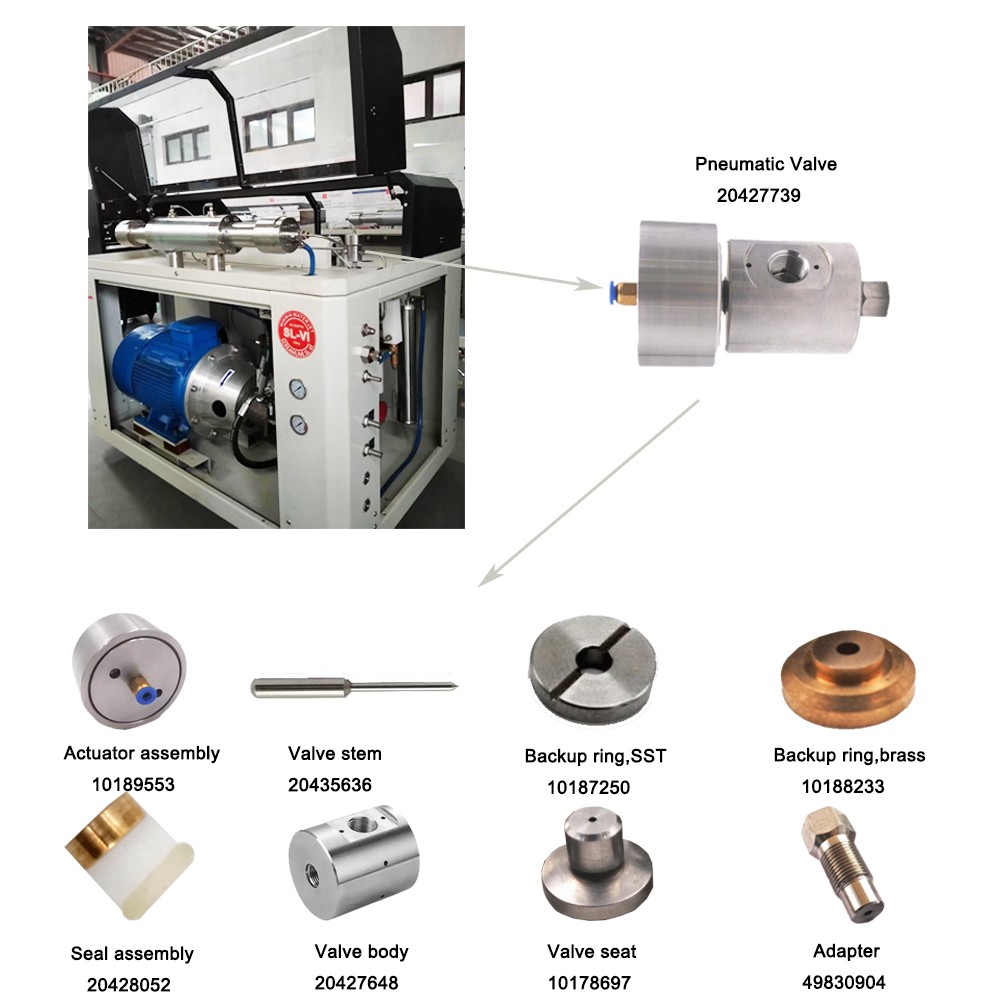

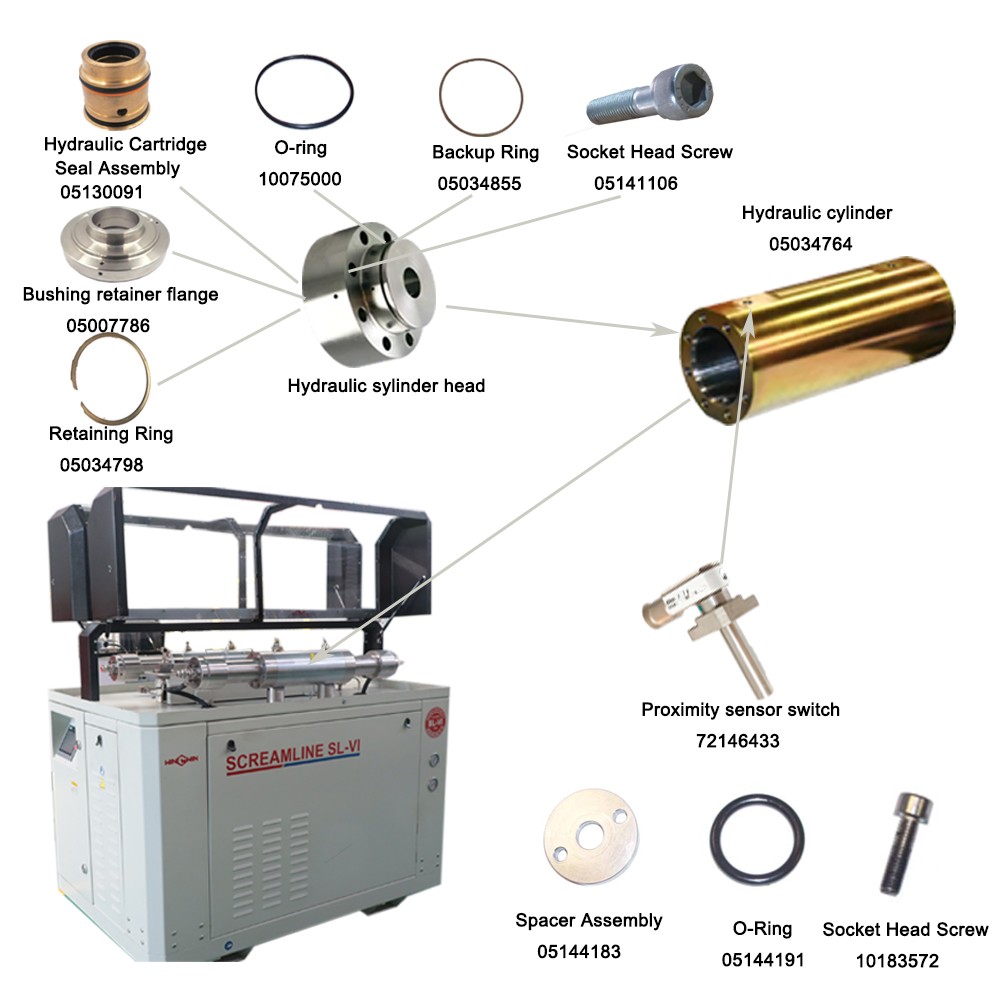

Water jet spare parts are the core part of intensifier pump. Without proper maintenance,it would cause downtime of your water jet cutting machine. So choosing reliable water jet spare parts is necessary.

wwaterjet

wwaterjet