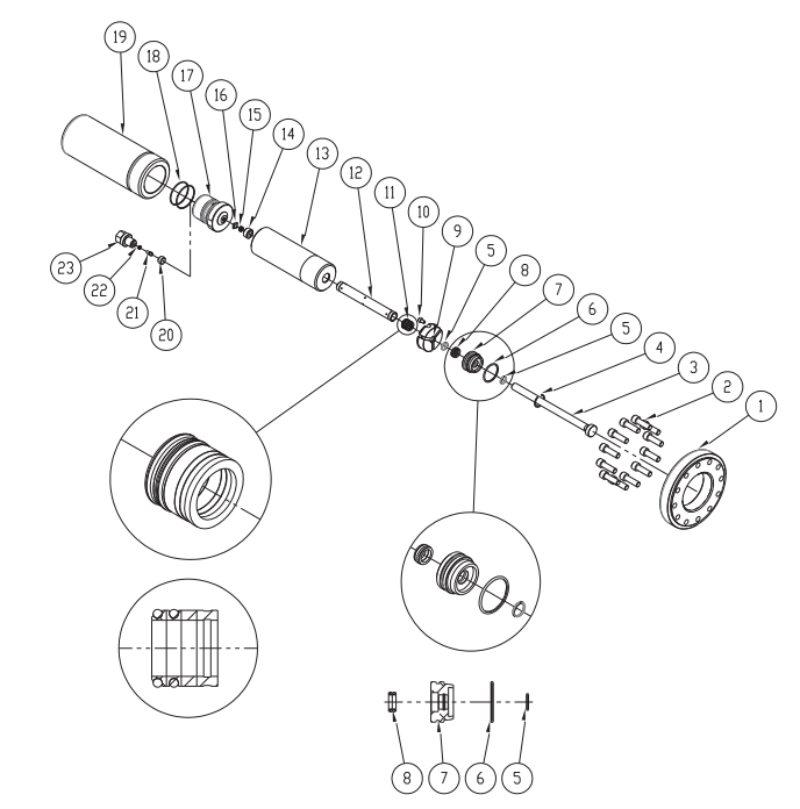

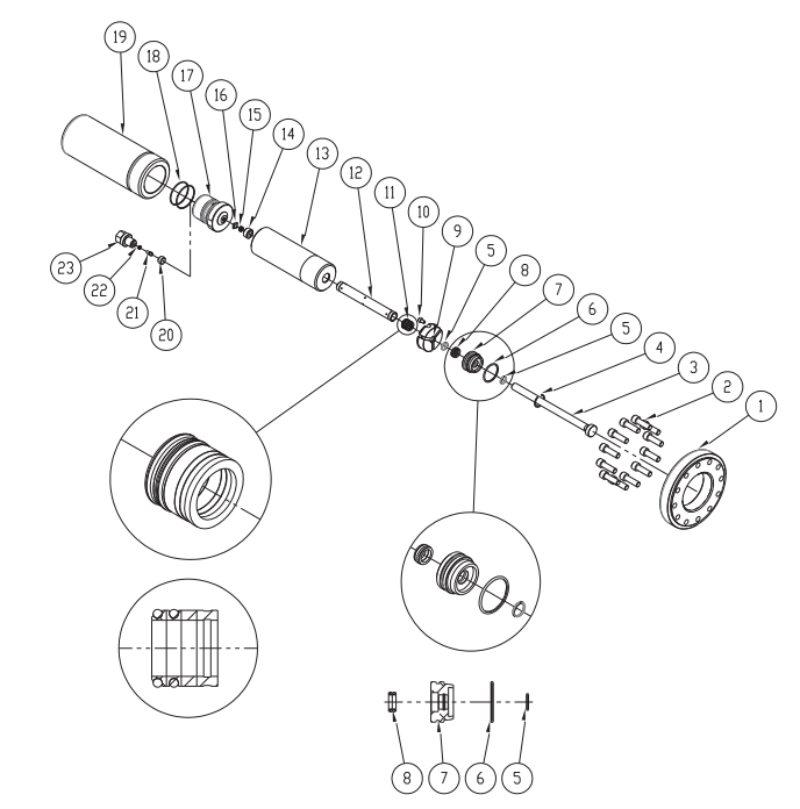

Techni Waterjet 501-1-0010 Internal Circlip

The TECHNI Waterjet 501-1-0010 Internal Circlip is a crucial component used in waterjet cutting systems to securely hold components in place within a housing or assembly. Internal circlips, also known as snap rings, are essential for maintaining the integrity and functionality of mechanical assemblies by preventing components from shifting or becoming dislodged during operation.

Key Aspects of the TECHNI Waterjet 501-1-0010 Internal Circlip

Material:

Dimensions:

Diameter: The circlip is designed to fit into a specific groove inside a bore or housing. The 501-1-0010 part number will correspond to precise dimensions that match the internal groove it is intended to fit.

Thickness: The thickness of the circlip must be appropriate for the groove to ensure a secure fit.

Design:

C-Shape with Open Ends: The circlip has a C-shape with open ends that allow it to be compressed and inserted into a groove. Once in place, the circlip expands to its original shape, securely holding components in position.

Functions of the Internal Circlip

Component Retention:

Vibration Resistance:

Maintenance Tips for Internal Circlips

Regular Inspection:

Proper Installation:

Clean Environment:

Corrosion Protection:

Troubleshooting Common Issues

Dislodged Circlips:

Wear and Deformation:

Corrosion:

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet