TECHNI waterjet LP Check Valve Spring 500-12-0040

Specifications and Considerations for Part 500-12-0040

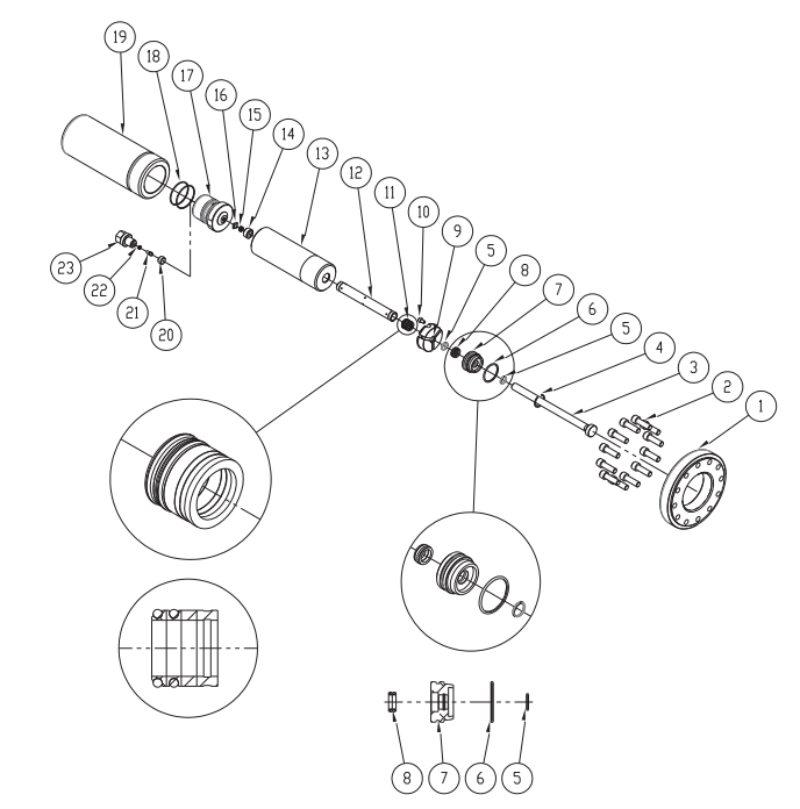

Compatibility: Ensure that the spring is compatible with the specific check valve model you are using. Part number 500-12-0040 should be verified against the valve manufacturer’s documentation.

Material: The material of the spring should be suitable for the operating conditions, including temperature, pressure, and the type of fluid used in the waterjet system. Common materials include stainless steel for corrosion resistance.

Dimensions: Verify the dimensions of the spring, including length, diameter, and wire thickness, to ensure it fits properly within the check valve assembly.

Cracking Pressure: Understand the required cracking pressure for your application and ensure the spring is rated accordingly. The cracking pressure affects the performance of the valve in your system.

Maintenance Tips

Regular Inspection: Periodically check the check valve and spring for signs of wear, corrosion, or damage. Replace the spring if it shows any signs of weakening or if the valve is not functioning correctly.

Cleanliness: Ensure that the valve and spring are kept clean to prevent debris from affecting the performance. Contaminants can cause the valve to stick or fail.

Lubrication: If applicable, use appropriate lubrication for the spring to reduce friction and wear. However, ensure that the lubricant is compatible with the system’s fluid.

Replacement: Always use OEM (Original Equipment Manufacturer) parts or equivalent quality replacements to maintain the integrity and performance of the system.

Troubleshooting Common Issues

Backflow or Leakage: If you experience backflow or leakage, inspect the spring for damage or weakening. Ensure the valve seat is clean and undamaged.

Valve Not Opening: If the valve does not open as expected, check for blockages, ensure the spring is not too stiff, and verify that the system pressure is sufficient to overcome the cracking pressure.

Noisy Operation: Unusual noises can indicate a problem with the spring or the valve seat. Inspect and replace any worn components as needed.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet