How to check whether a water cutting machine is practical

Waterjet cutting is a method often used in the field of modern cutting, which makes waterjet cutting machine more and more attention. When we inspect a waterjet cutting machine, we need to check many aspects to ensure the quality of the equipment and performance can meet the needs of use.

With the popularization of numerical control technology, there will be performance in water jet cutting machine, so the corresponding numerical control operation platform is also an important aspect. The form of the numerical control operating platform of the china water jet cutting machine is determined according to the shape, size and nature of the cutting material.

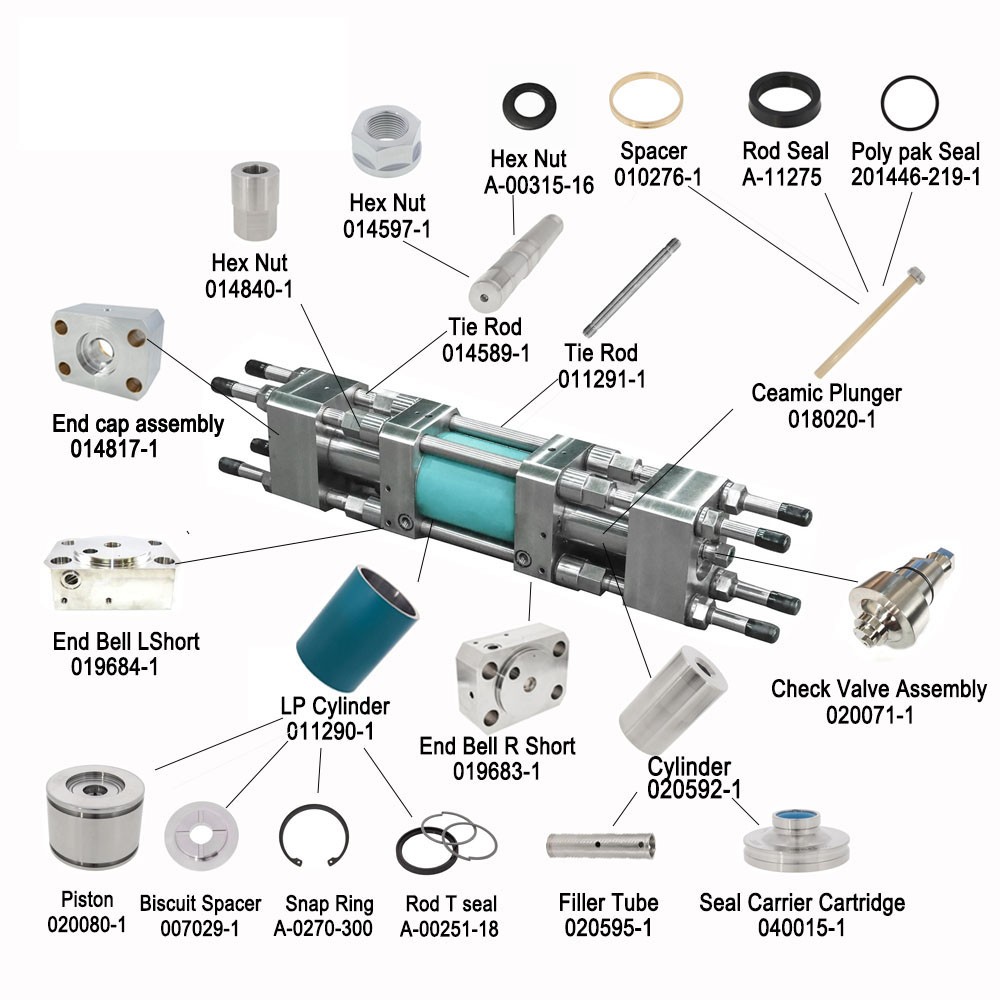

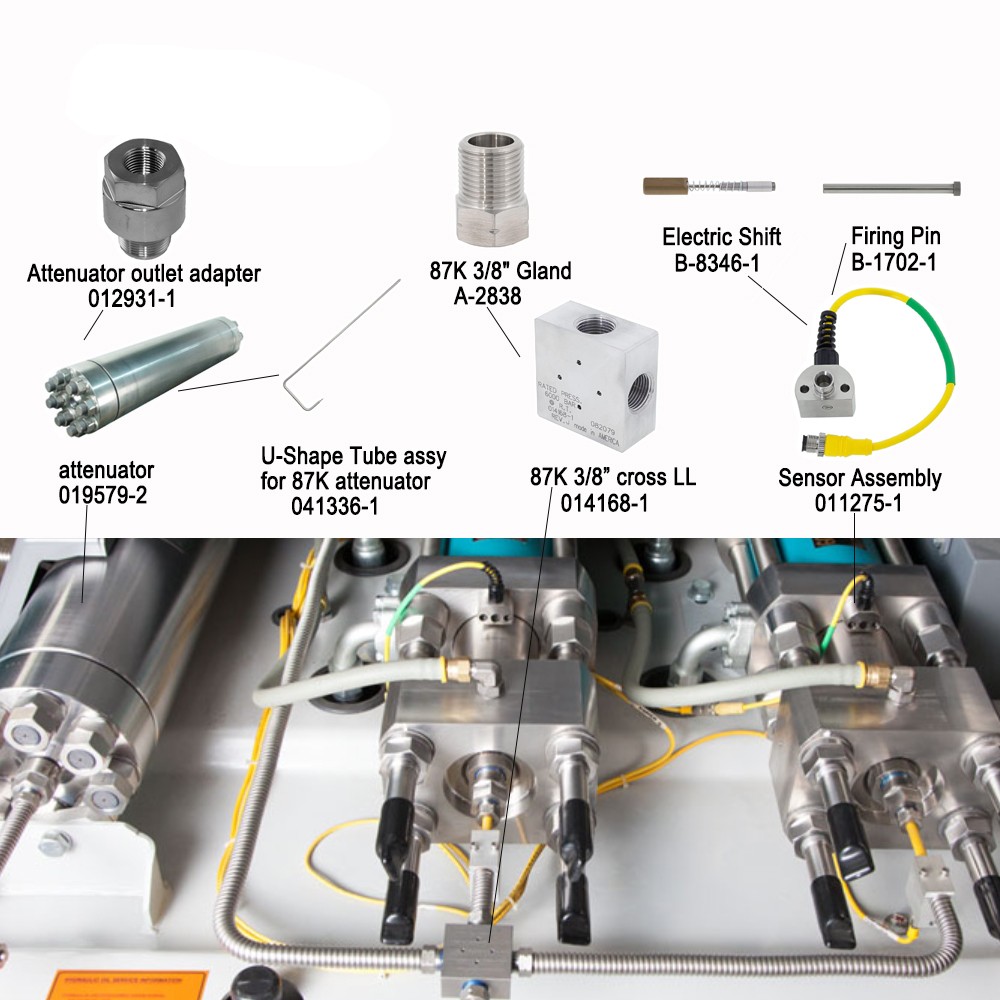

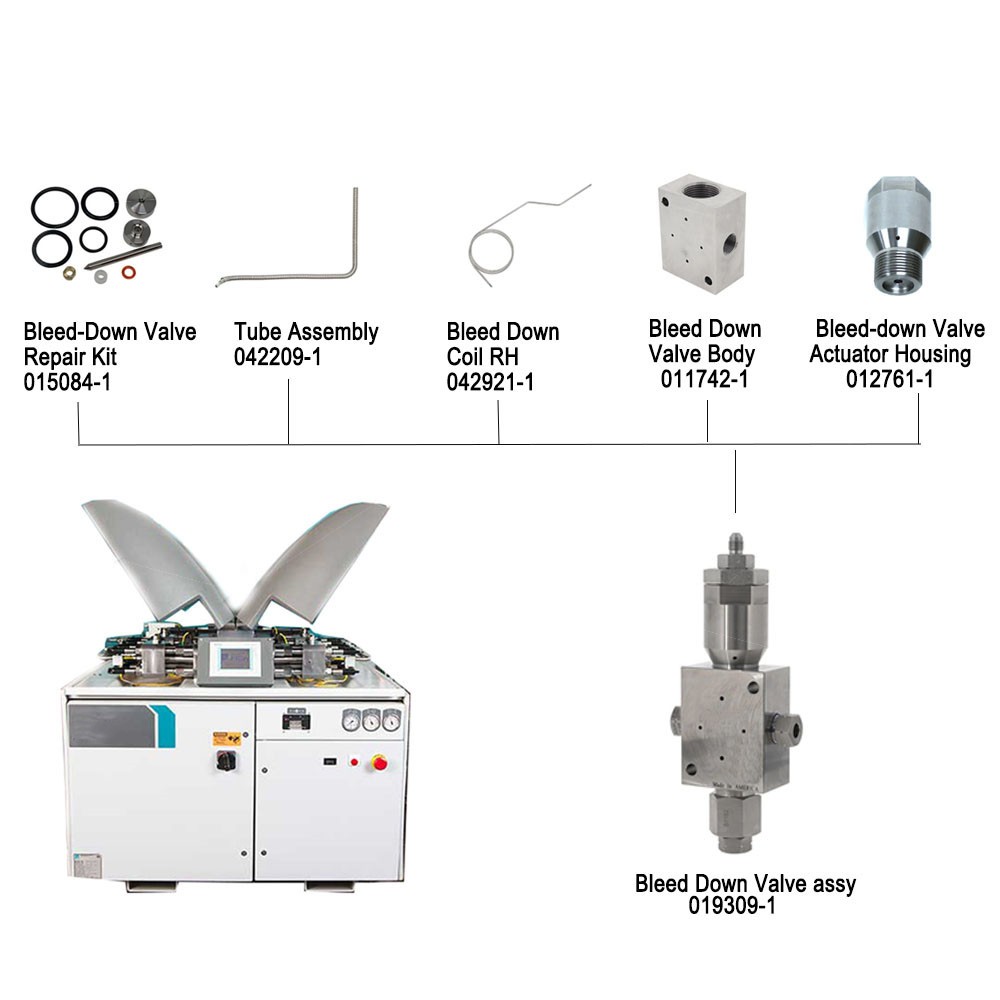

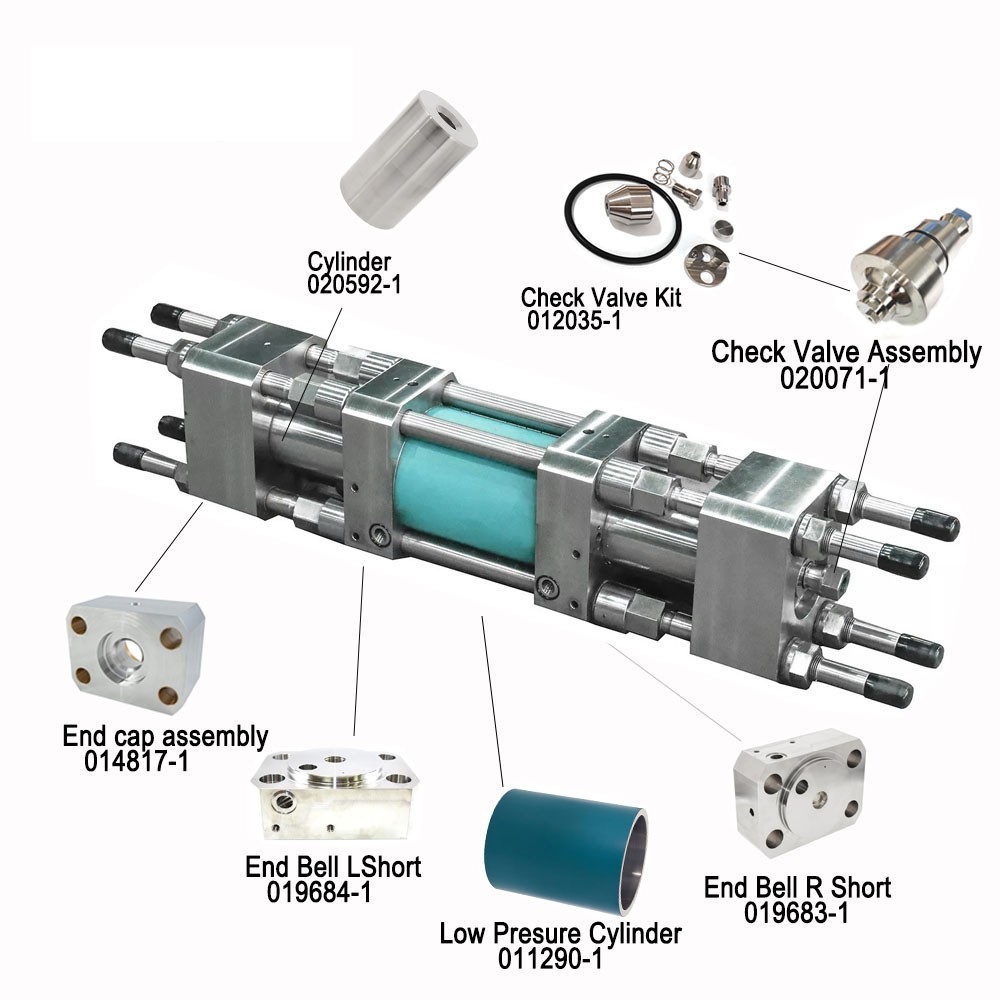

Another thing that is closely related to the cutting effect is the pressure system of the china water jet cutting machine, which is directly related to the cutting ability of the equipment. In order to maximize its utilization, it must also match the relevant performance of the cutting material. In addition to this, other accessories on the device cannot be ignored.

What impact does water jet cutting machine have on the whole environment

China water jet cutting machine has been widely recognized and developed with its unique way of speaking. From the perspective of the entire industry, the products also present structural, compact, and compound types. So what kind of problems exist in this kind of equipment and environmental problems?

Although the traditional cutting method can also get the ideal cutting effect, it is always contradictory to the environment, while the china water jet cutting machine mainly uses the effect of water to achieve the cutting purpose, so the improvement of environmental problems is obvious great.

The stone industry, which is closely related to china water jet cutting machine, also affects the entire industry. The acceleration of the standardization process is not only conducive to product competition, but also beneficial to the energy saving and emission reduction of processing enterprises. Since the material of the china water jet cutting machine cannot be post-processed naturally, it can effectively prevent the homogeneity of products between industries, thereby accelerating the development of the water jet machine industry.

What are the skills of abrasive waterjet cutting

In the process of using water jet, there are abrasive water jet cutting and pure water jet cutting, and each has its own characteristics and scope of application. The following is some experience summed up in the actual operation process to see what are the advantages of abrasive water jet cutting skills can be used?

Since the cutting speed of smaller abrasive particles is relatively slow, but the cutting effect will be relatively smooth, so the selection depends on the actual situation. If it is necessary to perforate some materials regularly, it is necessary to ensure the water pressure during the china water jet cutting machine process, so as to achieve the ideal perforation effect.

Abrasive waterjet uses water as the cutting medium, and the impurities in the water must be removed before use, so as to improve the service life of the equipment. If you make good use of water jet cutting, you can also greatly reduce the noise of the jet and maintain the stability of the work.

WIN-WIN china water jet cutting machine company

Due to its ideal cutting effect, china water jet cutting machine technology has attracted more and more users' attention. Many manufacturers will look for water jet cutting technology and water jet cutting equipment when processing. Do you know where there is a better china water jet cutting machine company in China?

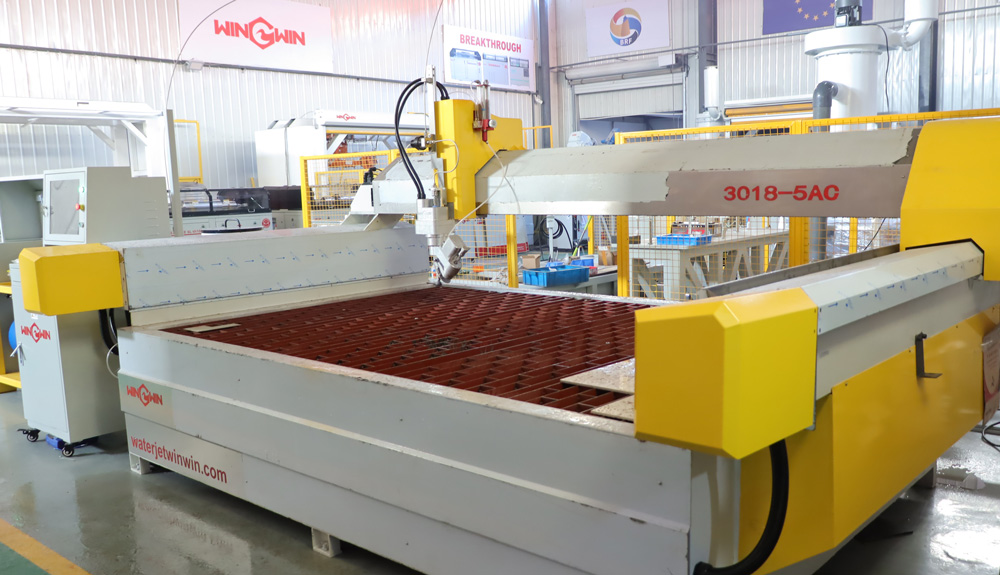

Generally speaking, WIN-WIN waterjet is a good choice. Wuxi Yongchang is a professional manufacturer engaged in the research, development, manufacture and sales of china water jet cutting machine. Not only the equipment is of excellent quality, but also very mature in time. It can provide cutting processing for customers, and can cut any plane on various materials. Used by many industries.

WIN-WINwaterjet cutting system is a fully numerically controlled machine manufactured by citing domestic technology, and the cutting is automatically controlled by computer, so the cutting accuracy is very high. Moreover, WIN-WIN waterjet cutting has more than ten years of experience, and is currently an expert in the field of china water jet cutting machine. It has a good reputation in various industries and is worthy of our trust.

Is waterjet cutting cheaper than laser cutting?

Generally, laser cutting costs about $13-$20 per hour, while waterjet cutting has a general range of $15-$30 per hour.

Why are water jet cutters so expensive?

Consumable materials such as water, fuel, and abrasive material also add to the overall expense. That's the raw expense alone. The pressure level also increases the cost significantly. Thicker materials require more power to cut, and it also needs more time.

wwaterjet

wwaterjet