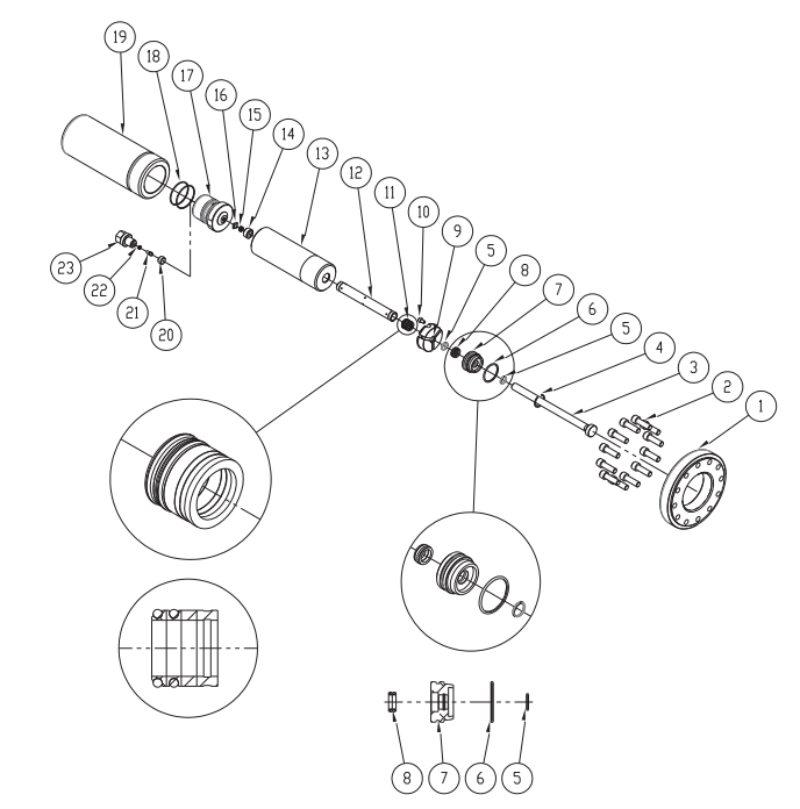

Techni Waterjet 500-20-0113 Outlet Poppet

The TECHNI Waterjet 500-20-0113 Outlet Poppet is a crucial component in TECHNI waterjet cutting systems. The outlet poppet plays a significant role in the high-pressure water delivery mechanism, ensuring that water flow is properly controlled and maintained during the cutting process.

Key Aspects of the TECHNI Waterjet 500-20-0113 Outlet Poppet

Material:

High-Grade Alloys: The outlet poppet is typically made from high-strength alloys or stainless steel to withstand the extreme pressures and wear conditions of waterjet cutting.

Durability: These materials ensure longevity and reliable performance under continuous operation.

Design:

Precision Engineering: The outlet poppet is precisely machined to fit seamlessly within the waterjet system, ensuring a tight seal and efficient operation.

Sealing Surfaces: Designed with high-quality sealing surfaces to prevent leaks and maintain consistent pressure.

Function:

Flow Control: The outlet poppet regulates the high-pressure water flow from the pump to the cutting head, ensuring precise and consistent delivery of water.

Backflow Prevention: It helps in preventing backflow, maintaining system pressure, and protecting the integrity of the waterjet system.

Maintenance Tips for Outlet Poppets

Regular Inspection:

Periodically inspect the outlet poppet for signs of wear, erosion, or damage. Regular inspections help in early detection of issues, preventing system failures.

Proper Installation:

Ensure the outlet poppet is installed correctly according to the manufacturer’s guidelines. Incorrect installation can lead to improper sealing and reduced performance.

Cleaning:

Keep the outlet poppet and its surrounding components clean to prevent contamination that could affect its operation. Use appropriate cleaning agents recommended by the manufacturer.

Replacement:

Replace the outlet poppet at regular intervals or when significant wear is detected to ensure optimal performance of the waterjet system.

Troubleshooting Common Issues

Leaks:

If leaks are detected, inspect the sealing surfaces of the outlet poppet and its housing. Ensure proper installation and check for any wear or damage that may be causing the leak.

Pressure Drops:

If there are unexpected drops in system pressure, the outlet poppet may be worn or damaged. Inspect and replace as necessary to maintain consistent pressure.

Inconsistent Flow:

Inconsistent water flow could indicate a problem with the outlet poppet. Inspect for blockages, wear, or incorrect installation.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet