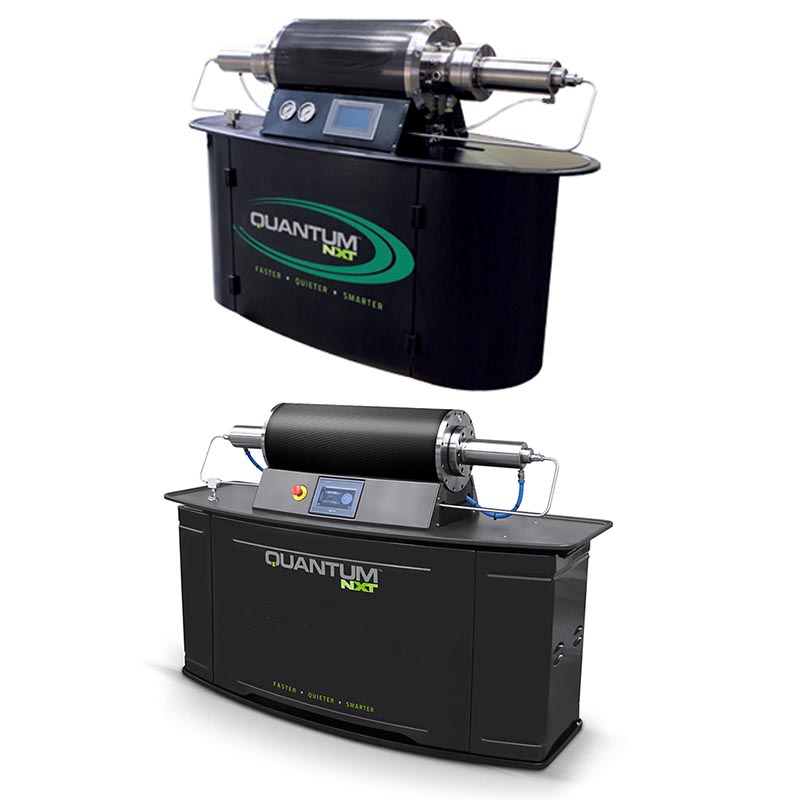

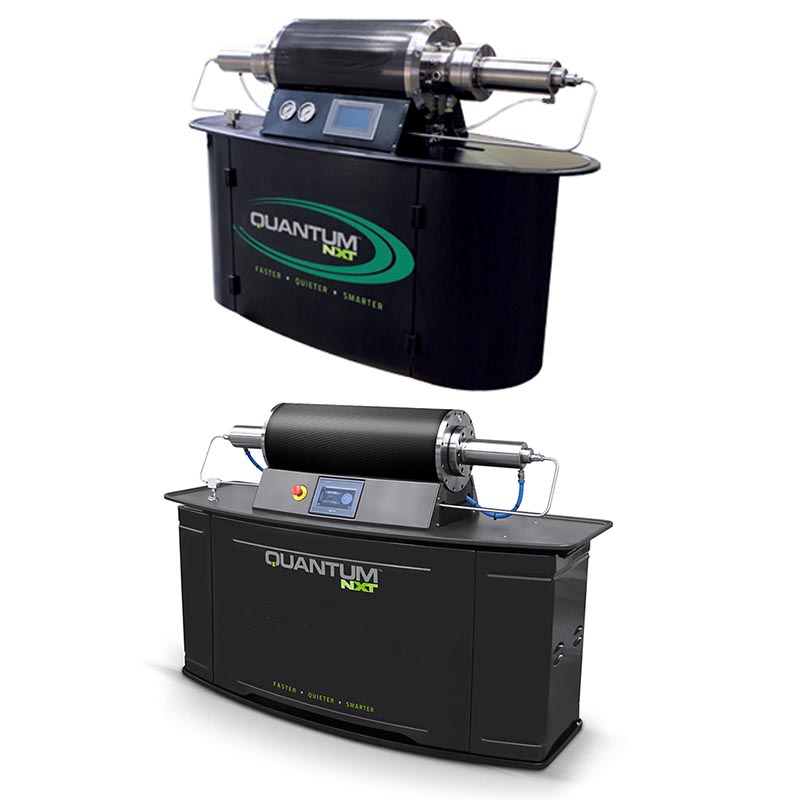

Techni Waterjet SP-72-7 LP Check valve housing

The TECHNI Waterjet SP-72-7 LP (Low Pressure) Check Valve Housing is a critical component in waterjet cutting systems, designed to house the check valve that regulates the flow of low-pressure water or fluid within the system. This housing ensures the check valve functions correctly, preventing backflow and maintaining system integrity.

Key Aspects of the TECHNI Waterjet SP-72-7 LP Check Valve Housing

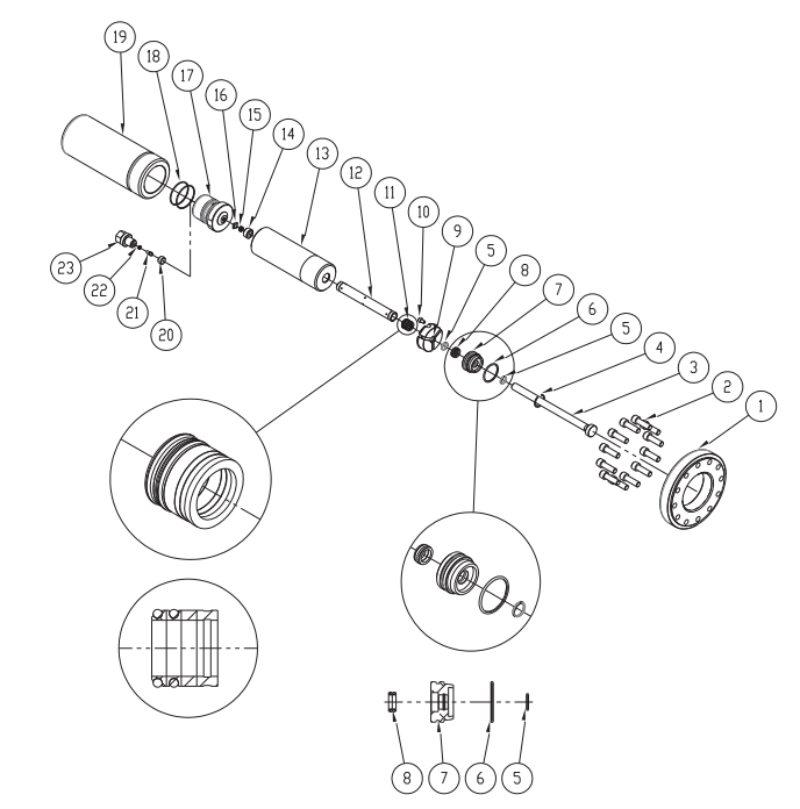

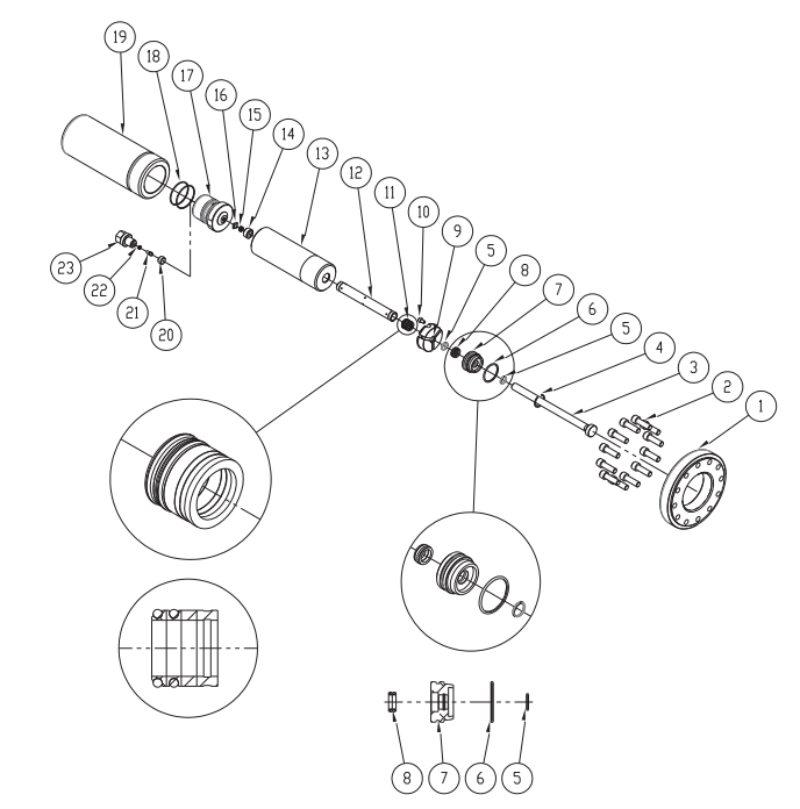

Material:

Stainless Steel or High-Grade Alloy: The housing is typically made from durable materials such as stainless steel or high-grade alloys to withstand the operating conditions of a waterjet system, including pressure, corrosion, and wear.

Design:

Dimensions:

The housing must match the specific dimensions required for the check valve it is designed to contain. This includes the internal diameter, length, and any specific features that align with the check valve and the overall system.

Functions of the LP Check Valve Housing

Check Valve Support:

Fluid Flow Regulation:

By housing the check valve, it helps regulate fluid flow, allowing fluid to pass in one direction while preventing backflow, which is essential for maintaining consistent system pressure and performance.

System Integrity:

Maintenance Tips for Check Valve Housing

Regular Inspection:

Periodically inspect the housing for signs of wear, corrosion, or damage. Ensure there are no cracks, deformities, or other issues that could compromise its integrity.

Proper Installation:

Cleaning:

Seal Inspection:

Troubleshooting Common Issues

Leaks:

Backflow Issues:

Corrosion or Wear:

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet