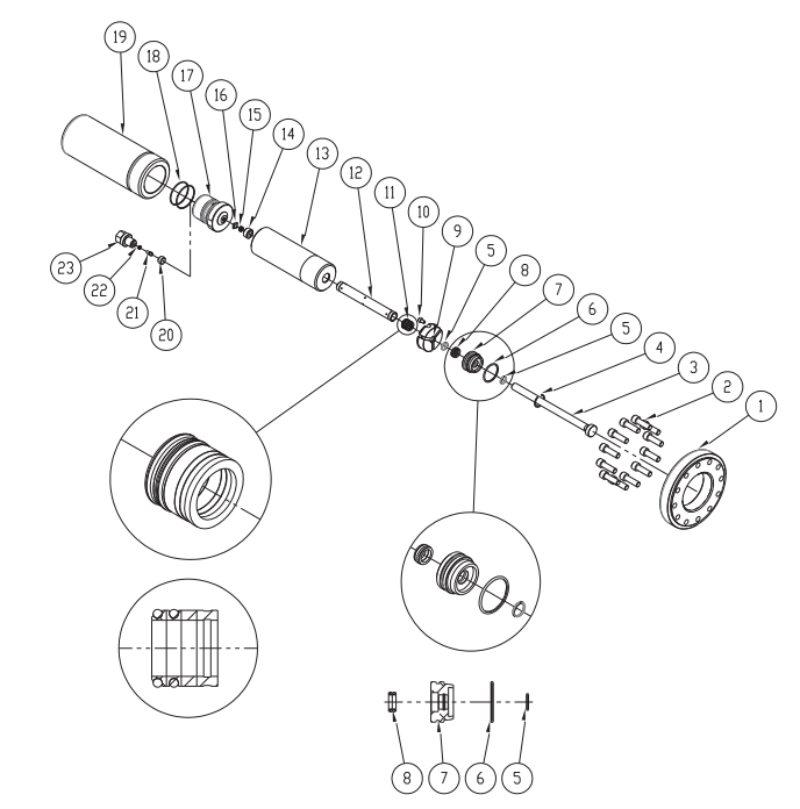

Techni Waterjet SP4-45-195 Seal Housing

The TECHNI Waterjet SP4-45-195 Seal Housing is an essential component in TECHNI waterjet cutting systems, designed to securely house and protect seals that maintain the integrity of high-pressure water systems. Proper functioning of the seal housing ensures efficient operation and longevity of the waterjet cutting system by preventing leaks and maintaining pressure.

Key Aspects of the TECHNI Waterjet SP4-45-195 Seal Housing

Material:

High-Grade Alloy or Stainless Steel: Typically made from high-strength materials such as stainless steel or specialized alloys to withstand high pressures and resist corrosion and wear.

Design:

Precision Engineering: Precisely machined to fit the specific dimensions and requirements of the waterjet system. The design ensures a secure fit for the seals, preventing leaks and maintaining system pressure.

Compatibility: Designed to be compatible with other components in the waterjet system, ensuring seamless integration and reliable performance.

Function:

Seal Protection: Houses the seals that prevent water from escaping the high-pressure system. The housing protects these seals from damage and ensures they remain in place.

Pressure Maintenance: Helps maintain the high pressure necessary for effective waterjet cutting by ensuring a tight seal within the system.

Maintenance Tips for Seal Housing

Regular Inspection:

Periodically inspect the seal housing for signs of wear, corrosion, or damage. Regular inspections help identify potential issues early and prevent system failures.

Proper Installation:

Follow the manufacturer’s guidelines for installing the seal housing to ensure it is properly seated and secured. Incorrect installation can lead to leaks and reduced performance.

Cleaning:

Keep the seal housing and surrounding components clean to prevent contamination that could affect the seals and overall system operation. Use appropriate cleaning agents as recommended by the manufacturer.

Seal Replacement:

Regularly check the seals housed within the seal housing and replace them as needed. Ensure that replacement seals are compatible with the seal housing and the waterjet system.

Troubleshooting Common Issues

Leaks:

If leaks are detected around the seal housing, inspect the seals and housing for wear or damage. Ensure the housing is properly installed and the seals are in good condition.

Pressure Drops:

Unexpected drops in system pressure could indicate issues with the seal housing or the seals it contains. Inspect for proper installation, wear, or damage and replace components as necessary.

Corrosion or Wear:

Regularly inspect the housing for signs of corrosion or wear, especially in harsh operating environments. Replace the housing if significant damage is detected to maintain system integrity.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet