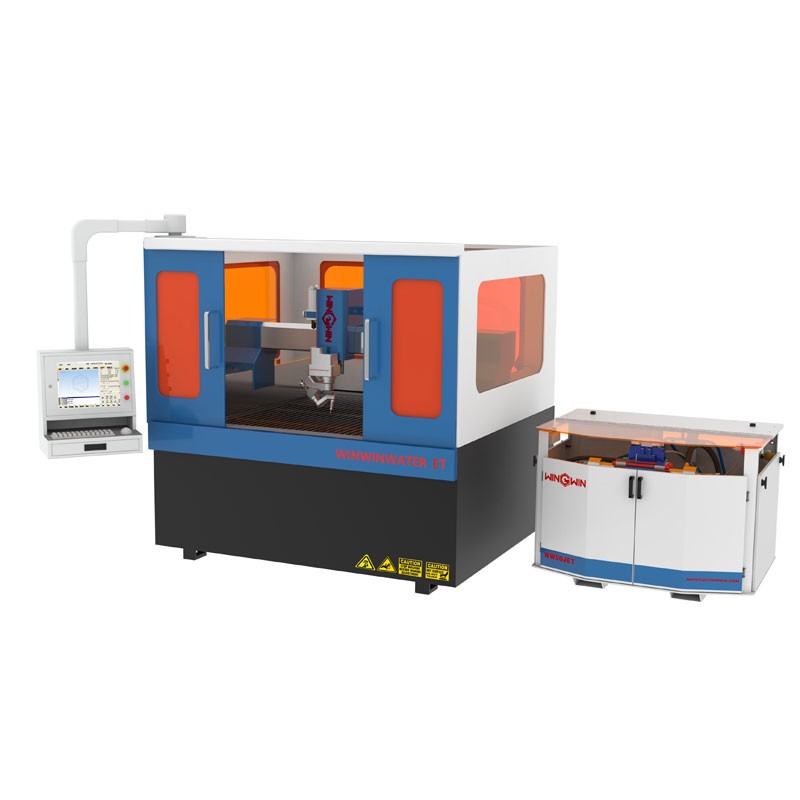

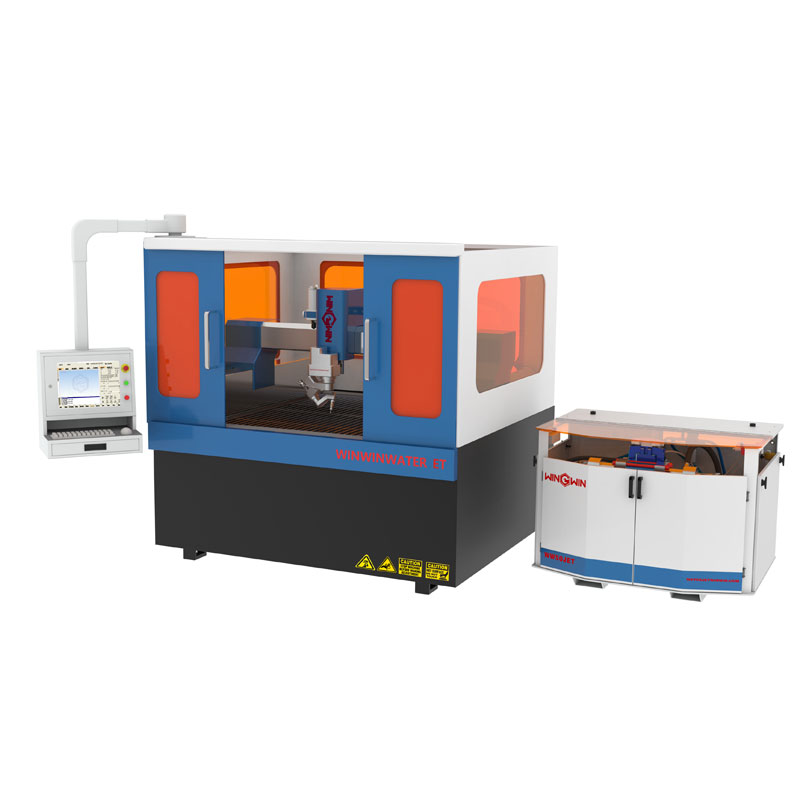

1M Full Colsed Small Abrasive Water jet Machine

A full closed small water jet machine offers several advantages:

Safety: One of the primary advantages is enhanced safety. The full enclosure prevents water from splashing outside the machine during operation. This reduces the risk of operators coming into contact with the high-pressure water jet, which can be dangerous.

Cleanliness: The closed design helps contain abrasive materials and water residues within the machine, minimizing the mess and making cleanup easier. This is particularly beneficial in environments where cleanliness is crucial, such as medical device manufacturing or food processing.

Noise Reduction: The enclosure helps dampen the noise generated by the water jet cutting process. This can improve the working environment by reducing overall noise levels, making it more comfortable for operators and nearby workers.

Environmental Control: Closed systems can incorporate features for managing water filtration and recycling systems more effectively. This can lead to more efficient use of resources and potentially lower operating costs.

Precision and Consistency: Enclosing the cutting area can help maintain consistent environmental conditions, such as temperature and humidity, which can influence cutting accuracy and material behavior. This is particularly important for precision cutting applications.

Compliance: In some industries, such as aerospace or automotive, full enclosure may be required to comply with safety and environmental regulations. Using a closed system ensures that the machine meets these standards.

Versatility: Despite being enclosed, modern small water jet machines can still offer versatility in terms of cutting a wide range of materials, from metals to composites to ceramics, with high precision and minimal heat-affected zones.

Rated Powe | 30KW/40HP | Max. operating pressure | Max. operating pressure |

Continuous working pressur | 320MPa-380MPa | Max. discharging rate | 3.8L/min |

Orifice diamete | 0.33mm or others | Nozzle diameter | 1.02mm or other |

Tank volume | 150L | Size | 1800mm*1100mm*1300mm |

Weight | 800kg |

JET50 Waterjet pump ————— Features

A. Beautiful appearance and reasonable design

The appearance is more exquisite and beautiful, small and exquisite, the main parts of the intensifier and accumulator are grouped together and installed above the center of the pump, with a transparent acrylic cover, which is convenient to observe the working status at any time.

B. High performance and standard design

Universal structure design, international standard spare parts. High versatility of accessories, customers can purchase the corresponding parts in any waterjet machine market.

C. Newly designed accumulator

Accumulator of new design, integrally forged, without rubber seals, maintenance-free.

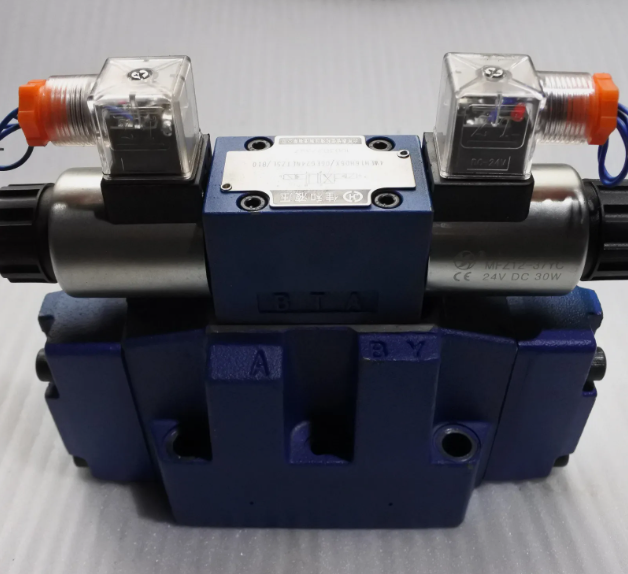

D. Double oil filtration system

Double filtration devices are placed at the oil inlet and oil return port to ensure that the oil path is clean, smooth and not blocked, and extend the service life of the waterjet pump.

| WEIHONG WATERJET CNC CONTROL SYSTEM | |

| Brand | WEIHONG® (ENGLISH) |

| Display | Industrial grade display |

| Language | English/Chinese//Others |

| System version | Win10 |

| Format | CAD/G/DXF/ENG/PLT, etc. |

| System Function | AC-5Axis/AB-3Axis |

CNC Control System————— Features

A.Industrial grade screen, special waterjet software, easy to operate.

B.Absolute encoder system, memory function after power failure.

C.Simulation operation, pause and start at any time, continue cutting from any position and point.

D. A more user-friendly and intelligent function has been added, namely the setting and recall function.

Specification for Abrasive Tank | |

| Wall Thickness | 4.5mm (Explosion proof) |

| Air Pressure | 0.2MPa-1MPa |

| Volume | 200kg |

Abrasive Feed Tank ————— Features

A. The automatic abrasive dispensing system continuously supplies abrasive to the abrasive regulator tank on the cutting head next to the large abrasive tank.

B. Without any electrical components, it is maintenance-free, zero defect.

C. Reasonable design enables this large capacity abrasive tank to cut 8-10 hours without interruption.

D. Large diameter flange at the bottom, easy to remove debris.

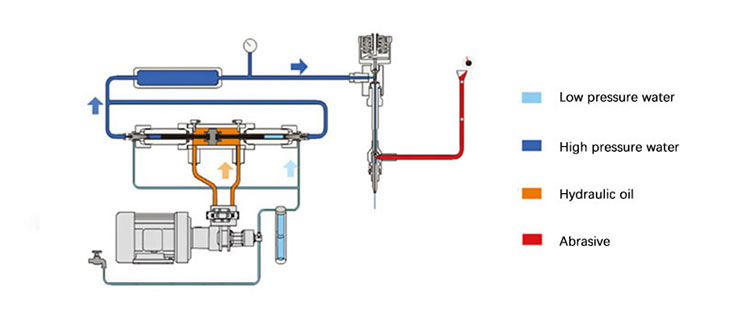

Specification for cooling:

As you know, the pump is driven by hydraulic oil for intensifier work.

Excessive temperature of hydraulic oil will seriously affect the service life of metal parts and sealing parts of the hydraulic part of the intensifier pump.

Refrigerator cooling with super cooling effect, closed internal circulation system, more environmental health, beautiful appearance, reliable performance.

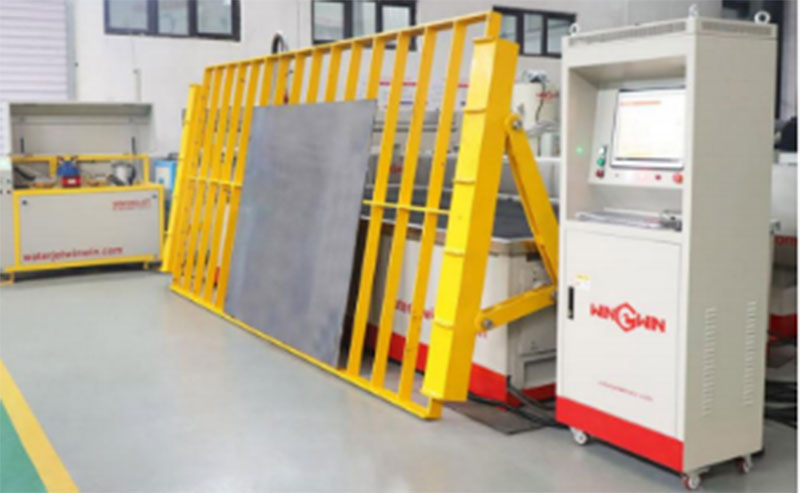

Loading and unloading device:

The functions of the waterjet cutting table loading and unloading tilting device include loading and unloading, which is very necessary for users who cut large and heavy materials.

This function can realize automated loading and unloading, reducing the operator's labor and time,and is very safe, improving cutting efficiency and accuracy.

If you are interesting other type of waterjet cutting machine,please contact me when you free.

wwaterjet

wwaterjet