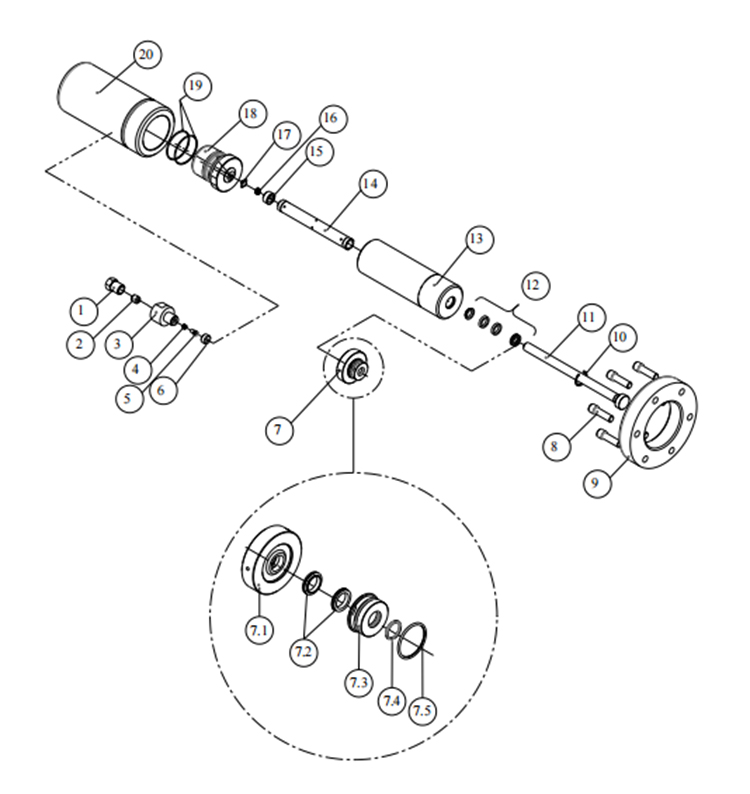

Techni Waterjet SP2-70-5 Cylinder retaining sleeve

The TECHNI Waterjet SP2-70-5 Cylinder Retaining Sleeve is a critical component used in TECHNI waterjet cutting systems. This retaining sleeve is essential for maintaining the integrity and performance of the cylinder assembly, which is a crucial part of the waterjet system's high-pressure mechanism.

Key Aspects of the TECHNI Waterjet SP2-70-5 Cylinder Retaining Sleeve

Material:

The retaining sleeve is typically made from high-strength materials, such as stainless steel or other durable alloys, to withstand the high pressures and stresses experienced in a waterjet cutting system.

Function:

The primary function of the cylinder retaining sleeve is to secure and maintain the position of the cylinder within the assembly. It ensures that the cylinder operates correctly under high-pressure conditions without any displacement or misalignment.

Compatibility:

The SP2-70-5 retaining sleeve must be compatible with the specific cylinder and overall assembly it is designed for. This ensures proper fit and function, maintaining the integrity of the high-pressure system.

Maintenance Tips for Cylinder Retaining Sleeves

Regular Inspection:

Periodically inspect the retaining sleeve for signs of wear, corrosion, or damage. Regular checks help ensure that the sleeve remains in good condition and continues to perform its function effectively.

Proper Installation:

Ensure the retaining sleeve is installed correctly, following the manufacturer’s guidelines. Improper installation can lead to misalignment or failure under pressure.

Torque Specifications:

When installing the retaining sleeve, use the correct torque specifications to avoid over-tightening or under-tightening, which can compromise the sleeve's integrity and the overall assembly.

Lubrication:

Apply appropriate lubricants during installation to reduce friction and prevent galling or seizing of the components. Ensure that the lubricants used are compatible with the materials and operational conditions of the waterjet system.

Troubleshooting Common Issues

Misalignment:

If there is misalignment in the cylinder assembly, check the retaining sleeve for proper installation and any signs of wear or damage. Correct any issues to ensure proper alignment and function.

Leaks:

Inspect the retaining sleeve and associated seals if leaks occur in the cylinder assembly. Ensure the sleeve is correctly positioned and that all seals are intact and in good condition.

Wear and Tear:

Regular wear and tear can degrade the retaining sleeve over time. Replace the sleeve as needed to maintain the integrity and performance of the waterjet system.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet