Techni Waterjet O-ring Nitrile 500-5-0048

The TECHNI Waterjet O-ring Nitrile 500-5-0048 is a critical sealing component designed for use in TECHNI waterjet cutting systems. Nitrile, also known as Buna-N, is a synthetic rubber copolymer known for its excellent resistance to oils, fuels, and other chemicals, making it an ideal material for sealing applications in industrial environments.

Key Aspects of the TECHNI Waterjet O-ring Nitrile 500-5-0048

Material:

Nitrile (Buna-N): Nitrile O-rings are chosen for their durability and resistance to a wide range of chemicals, particularly petroleum-based oils and fuels. They also offer good mechanical properties, including high tensile strength and resistance to abrasion.

Dimensions:

The specific dimensions of the O-ring, including its inner diameter (ID), outer diameter (OD), and cross-sectional thickness (CS), are crucial for ensuring a proper fit and seal within the waterjet system. These dimensions should be verified based on the specific application requirements and the technical documentation provided by TECHNI.

Compatibility:

Nitrile O-rings are suitable for applications involving contact with oils, water, and hydraulic fluids. They have a good temperature range, typically from -30°C to +100°C (-22°F to +212°F), which makes them suitable for many industrial environments.

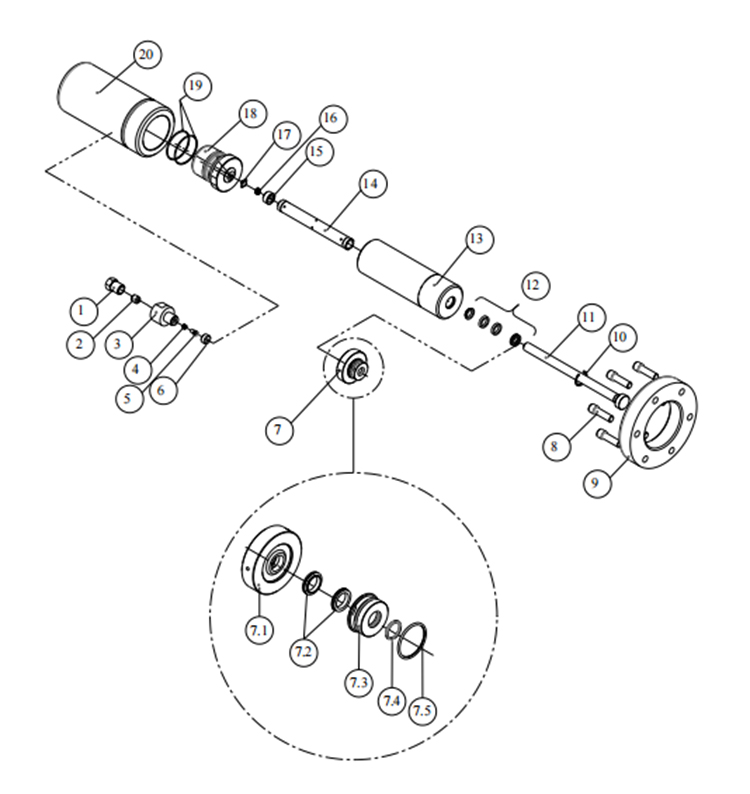

Functions of the O-ring

Sealing: Provides a reliable seal between connected components to prevent leaks and ensure system integrity.

Pressure Maintenance: Maintains high-pressure conditions within the system, which is essential for the effective operation of waterjet cutting.

Protection: Prevents contaminants from entering the system, thereby protecting internal components and maintaining performance.

Maintenance Tips for O-rings

Regular Inspection: Frequently inspect O-rings for signs of wear, cracking, or other forms of degradation. Replace any O-rings that show signs of damage.

Proper Installation: Ensure correct installation by avoiding twisting or stretching the O-ring. Use appropriate tools and lubrication during installation to prevent damage.

Lubrication: Use compatible lubricants to ease installation and ensure a proper seal. This also helps to prolong the lifespan of the O-ring.

Storage: Store spare O-rings in a cool, dry place away from direct sunlight and chemicals that could cause degradation.

Troubleshooting Common Issues

Leaks: If leaks occur, inspect the O-ring for damage or improper installation. Ensure the O-ring is the correct size and material for the application.

Pressure Drops: A damaged or improperly seated O-ring can lead to pressure drops. Inspect and replace the O-ring as necessary to maintain system pressure.

Degradation: Exposure to incompatible fluids or extreme temperatures can degrade the O-ring material. Verify that the material is suitable for the specific operating conditions.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet