11328 On/Off Valve Repair Kit Tech-Head Option Parts List

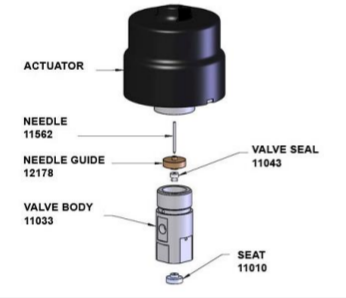

Valve Body Components The needle, needle bearing, valve seal, and seat are the working parts of the high-pressure valve.

These parts can be replaced either as a kit or individually as leaks occur.

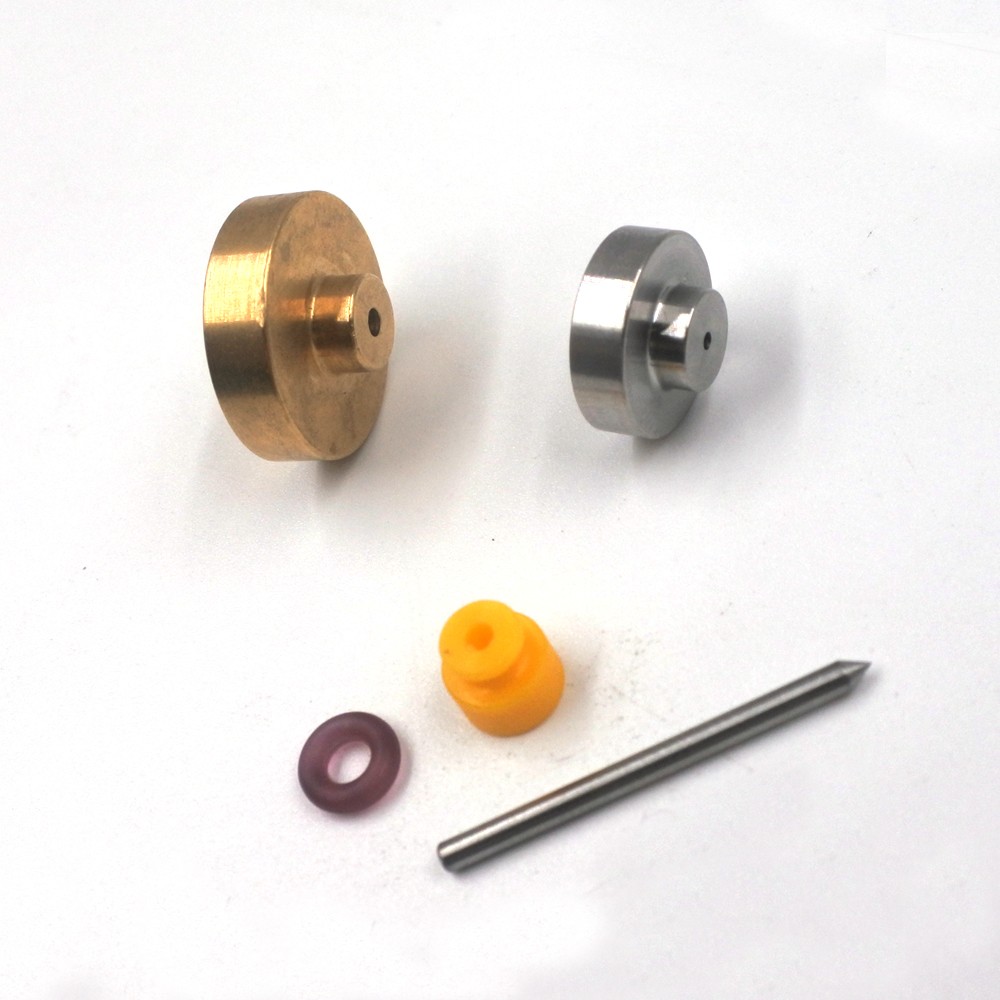

The ON/OFF valve repair kit #11328 should contain the following parts.

• 11562-NEEDLE

• 12178-NEEDLE GUIDE

• 11043-VALVE SEAL

• 11010-SEAT

When to Install New Valve Components

• Replace the needle and seat when the nozzle tip is dripping.

• Install a new seal when the top weep hole in the valve body is dripping.

• Replace the Needle Guide when the fit between the guide and needle is loose.

A worn guide ID may cause seals to fail due to ID extrusion.

*Dripping from the inlet water connection usually indicates that the connection is not tight enough

Removing the Valve Body components.

1. Isolate the water pressure from the ON/OFF valve by stopping the pump and verifying the pressure has dumped from the system.

2. Turn the actuator ON and verify that there is NO water pressure.

3. With the actuator pressurized with air, unthread the adapter/nozzle tube from the bottom of the valve body and remove the seat

from the bottom.

4. Turn the air to the actuator OFF and REMOVE the airline from the side of the actuator.

5. Unthread the actuator from the top of the valve body.

6. With the valve body still in the mounting collar, remove the seal components by using the seal removal tool 11205 and push

up through the bottom of the valve body.

7. Thoroughly wash out the interior of the Valve Body before replacing components. NOTE: The needle guide ID may have build-up

of seal material at the bottom of the .093 dia section. After extensive use, this build-up may stop the needle from closing. If the Guide

ID is going to be re-used, it must be cleaned. A .093 drill bit can be used, to manually remove this material.

Installing new Valve Body components.

1. Place the needle bearing over the needle with the needle going through the vent hole side.

2. Place the valve seal with the o-ring side out over the end of the needle.

3. Lubricate the o-ring on the valve seal with seal grease (not Goop) and insert into the top of the valve body until the needle guide is

flush to the top of the bore.

4. Apply goop to the actuator tread and hand tighten the actuator onto the top of the valve body. Reattach air to the actuator and turn

actuator air pressure on to pull the needle valve up, then fully tighten the actuator.

5. Apply Pure Goop to the surfaces at the top of seat and to the surface of the seat where the needle seats.

6. Place the seat into the pilot diameter at the top of the adapter/nozzle tube and thread the adapter/nozzle tube into the bottom of the

valve. Torque the adapter/nozzle tube to the valve using the two-wrench technique.

7. Turn off the air to the actuator.

8. Reapply high-pressure water to the valve and check for leaks.

9. Apply water pressure to the valve assembly to verify there are no leaks. Before installing the Cutting Head quickly cycle the Valve

on and off a few times to purge all contaminants. Reinstall the Cutting Head and commence cutting.

If you are searching 11328 On/Off Valve Repair Kit Tech-Head Option Parts List,contact wwaterjet.

wwaterjet

wwaterjet