Common questions of water jet cutting machine

As a kind of cutting equipment, waterjet has been well known by many users, but there are still many users who have some misunderstandings when purchasing waterjet, probably because they do not know enough about this product. In order to eliminate these misconceptions, the editor summarizes some key points of the water jet, hoping to be helpful.

For waterjet, although only from a certain angle, its cutting speed can be calculated. However, in the cutting process, in addition to the material and thickness of the material, other factors will also affect the cutting speed, and under the influence of time, the changes in the cutting speed are also different. It can be concluded that the cutting speed of the water jet cannot be accurately measured.

Some waterjet manufacturers will provide customers with reasonable gantry and cantilever cnc water jet cutting machine price, and most people think that the gantry cnc water jet cutting machine price is higher than the cantilever. In fact, there is not much difference between these two water jets, especially in terms of cutting accuracy. If you have to say the difference, the gantry waterjet is also prone to deformation.

How to implement a series of automatic functions in the water jet cutting machine

The waterjet cutting machine has realized the automation process, and the whole cutting process is divided into many steps, so how is the automatic nesting realized?

A series of automatic operations of the water jet machine are controlled by computer. There is an external file analysis interface provided inside the equipment system, which can read various external information. The nesting is also automatically realized through this system. Firstly, corresponding functional modules are established according to the actual production requirements for the operation of the cutting machine, including file management functions, parts management functions, system management functions, and so on.

To achieve the ideal cutting effect, the automatic nesting function and cutting simulation function are indispensable, which can provide automatic discharge on the sheet for the cutting process, and solve the need for NC code correctness verification, greatly improving the product quality. Cutting accuracy.

Selection principle of intensifier for water jet cutting machine

The normal operation of the waterjet machine is inseparable from some key accessories, including the added part. The waterjet machine can successfully complete the cutting operation under the condition of sufficient pressure. How is the additional device matched with the image of the waterjet machine formed?

In fact, it is very simple. There are intensifier pumps specially used for supercharging on the market, and the water jet machine is also equipped with this device. The difference between the two is obvious. Since we started relatively late in water jet technology, the corresponding technical level is definitely not as good as that of foreign countries. But the reason why the domestic intensifier pump can also be welcomed by the majority of users is mainly because cnc water jet cutting machine price is low, as long as the domestic cnc water jet cutting machine price is reasonably arranged, it can also meet the pressure demand. Generally speaking, domestic cnc water jet cutting machine price are mostly used for pressure requirements below 2500bar, such as cutting ceramic tiles, stone, glass and other materials.

Which components can be the heart of a waterjet

When you need to measure the quality of a piece of equipment, you generally turn your attention to the various core components on the equipment, and the same is true for water jet.

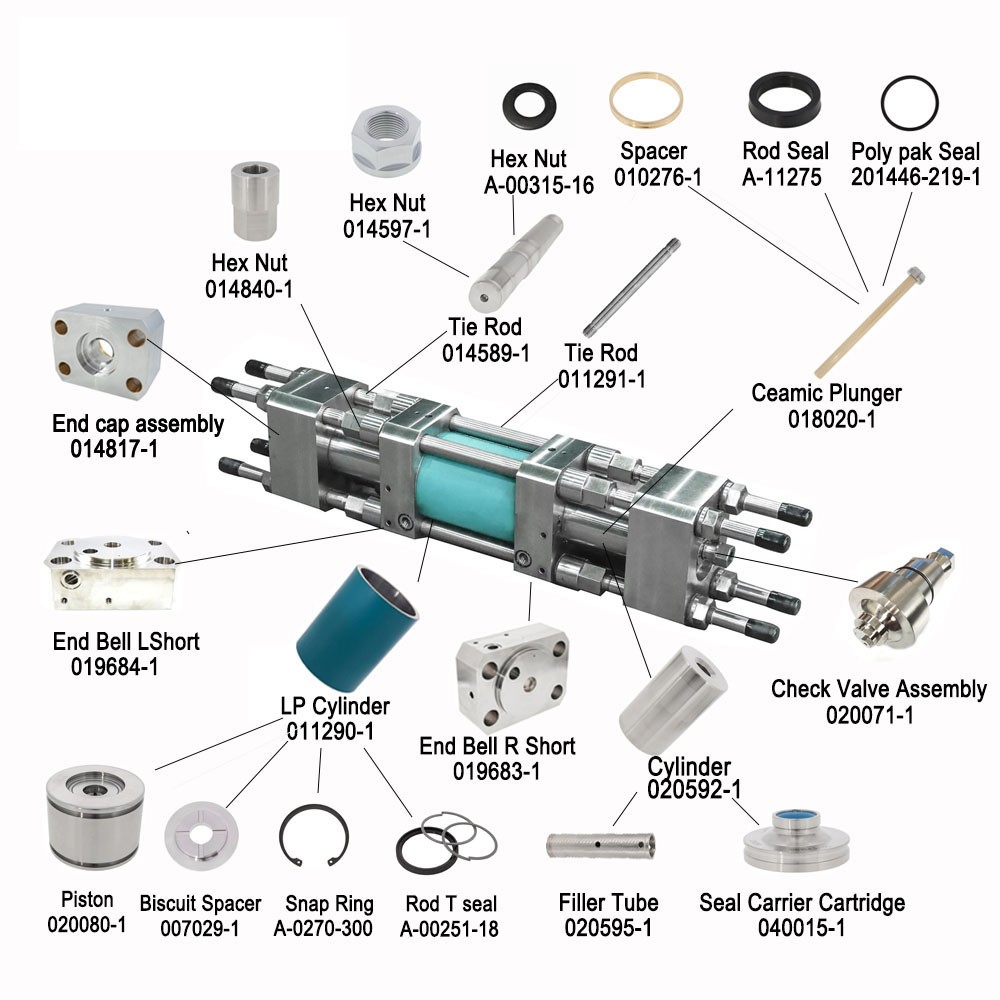

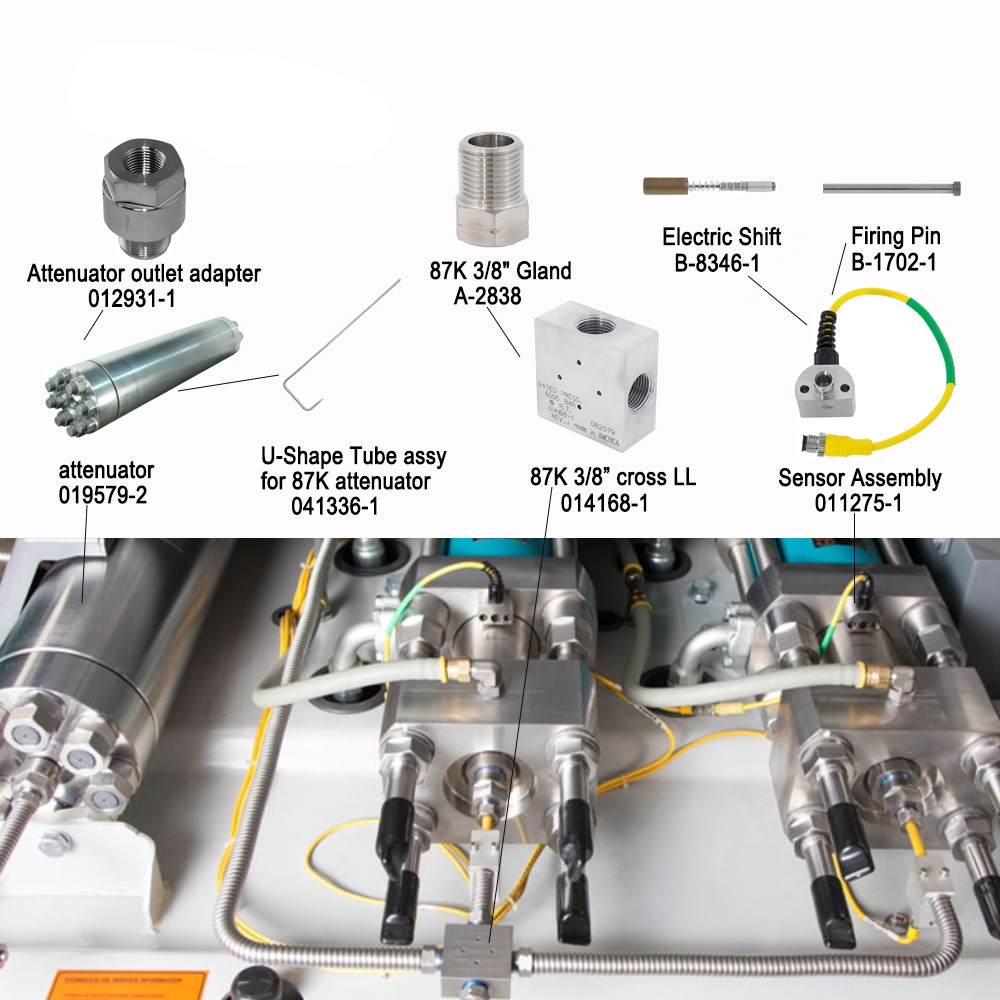

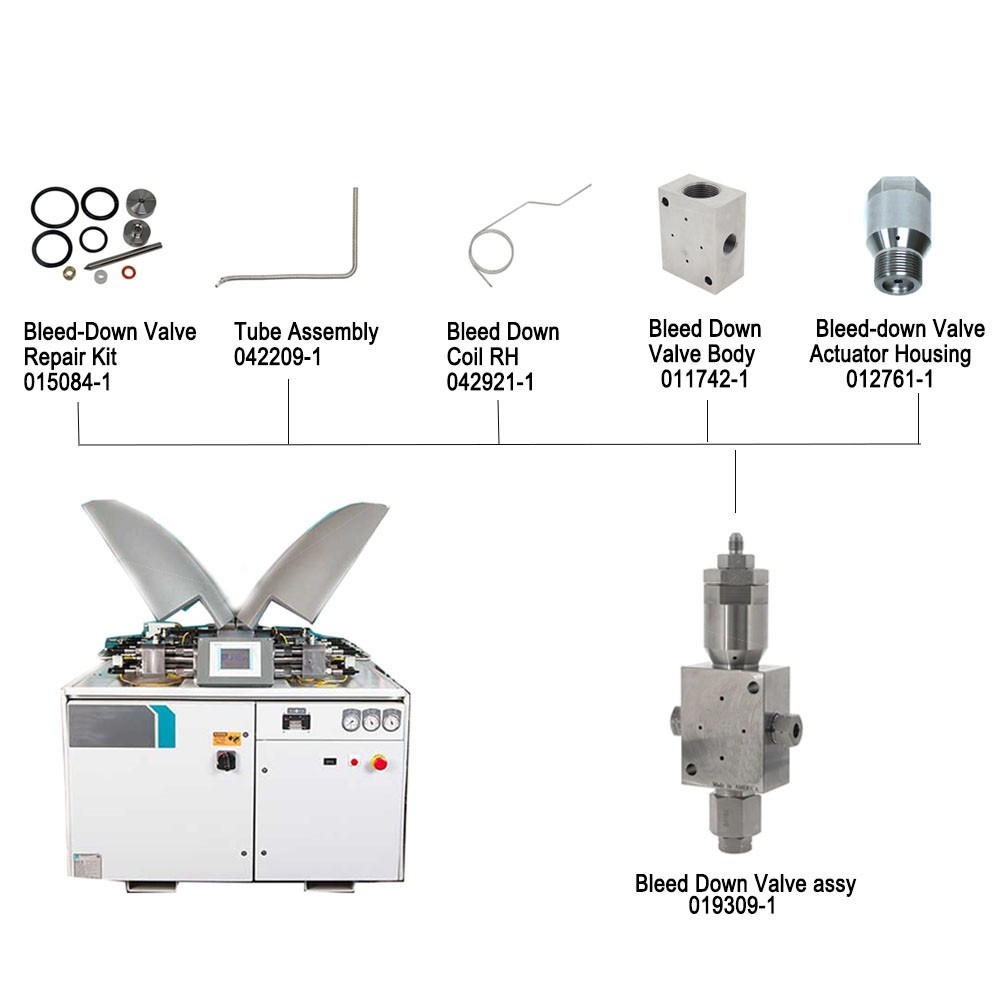

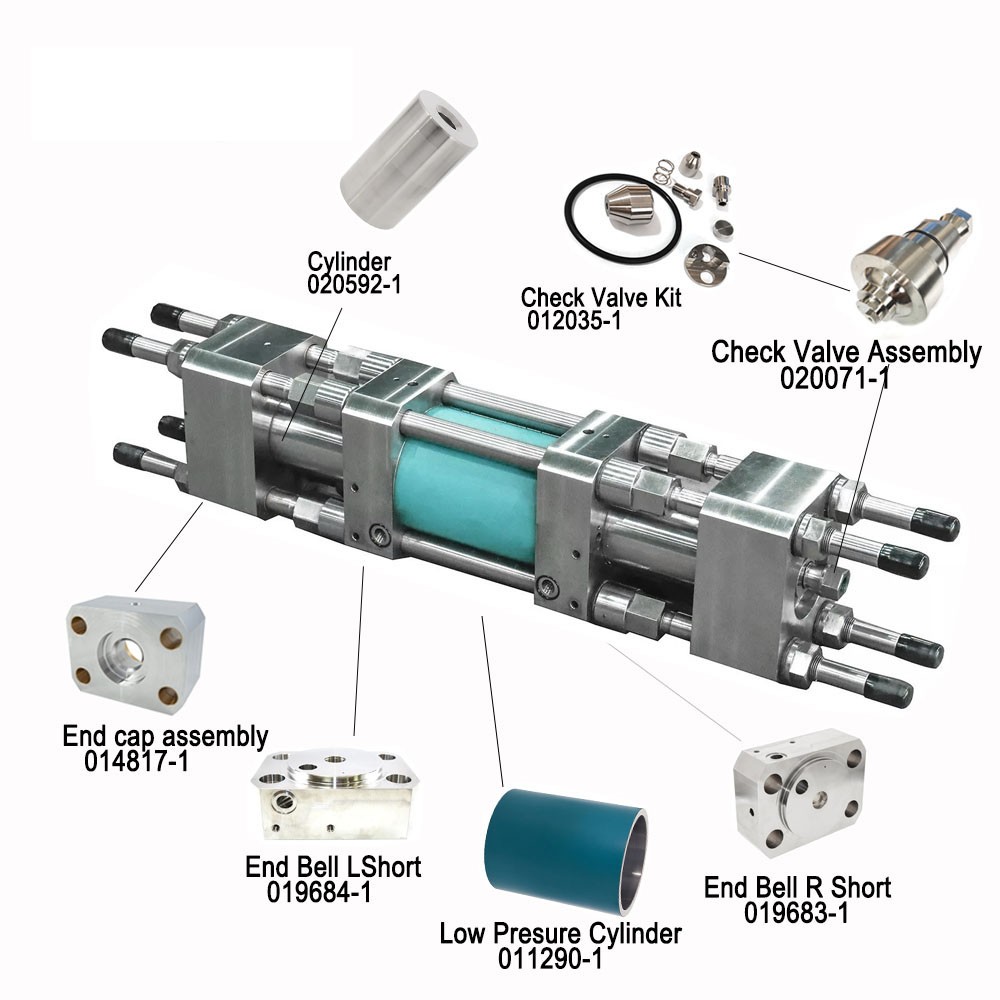

There are many core components that can affect the overall performance of the waterjet, such as high-pressure cylinders, accumulators, high-pressure plungers, high-pressure seals, check valves and other components. If one component fails, the waterjet may malfunction. So when identifying parts, we must be careful.

At present, there is no common standard in the waterjet industry, and the versatility of parts is not strong. Therefore, while paying attention to the quality, we should also pay attention to the price, not only the cnc water jet cutting machine price, but also the price of parts.

What is the cnc water jet cutting machine price?

While there are several factors that can affect the hourly cost of running a waterjet, on average, cnc water jet cutting machine price can be anywhere between $20/hr - $40/hr to run a waterjet with a single abrasive cutting head at 60,000 psi (does not include labor or capital repayment).

Why is cnc water jet cutting machine price so expensive?

Consumable materials such as water, fuel, and abrasive material also add to the overall expense. That's the raw expense alone. The pressure level also increases the cost significantly. Thicker materials require more power to cut, and it also needs more time.

Is cnc water jet cutting machine price more expensive than laser cutting?

For example, laser cutting is the cheapest option when cutting thin parts. However, cnc water jet cutting machine price is more cost-effective if thicker parts are being processed.

So if you want to buy cost-effective cnc water jet cutting machine price,please choose WIN-WIN waterjet. We can design the right waterjet cutting solution which can meet your demand.

wwaterjet

wwaterjet