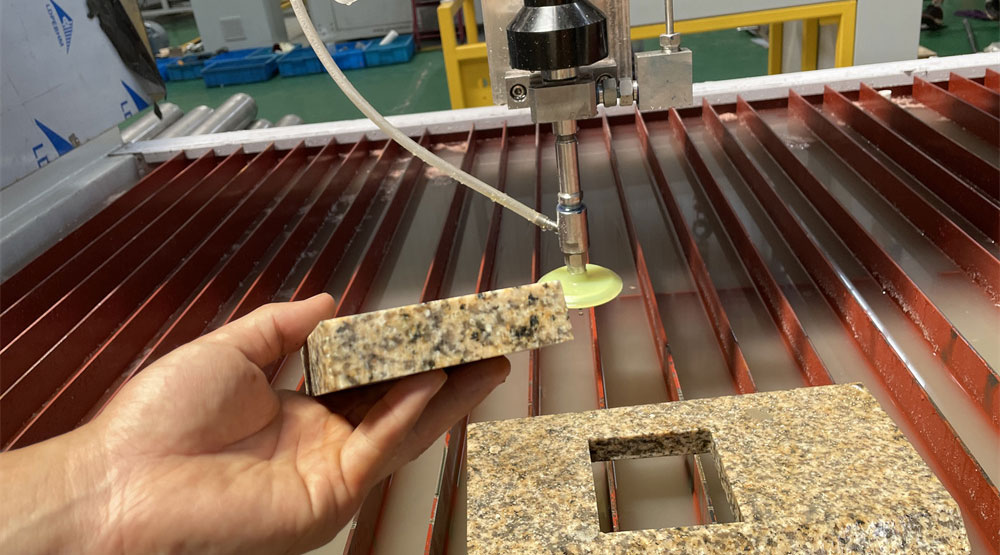

Water jet stone cutting machine for stone processing

First of all, what are the existing cutting processes? Including water jet stone cutting machine, wire cutting, laser cutting, etc., in terms of characteristic analysis, do these methods correspond to stone line processing? Let’s start with the material processing procedure. The conventional way is to use a circular saw blade to cut the stone into strips, and then use a milling wheel to mill and shape it. This is for wide and narrow floral wires; while using a diamond bead saw cutting is suitable for relatively wide floral wire.

With water jet cutting and laser cutting, there is no need to be so complicated. As long as these equipment and processes are used, the stone can be easily cut into the required size and shape. The whole process is efficient, stable, safe and trustworthy.

With the advancement of technological means, the scope of application of water jet stone cutting machine has been further expanded. In addition to the cutting of conventional machine parts, it is now also used in the shape processing of measuring tools. Vernier calipers are one of the beneficiaries. Compared with the traditional processing technology, what changes has the application of water jet stone cutting machine brought?

Due to the particularity of production, the vernier caliper as a measuring tool has high requirements on the production process, even its ruler frame cannot be sloppy. In the past, the milling machine was used to process this part of the workpiece, but it was found that the processing effect was easily affected by various factors, including molds, material properties, equipment performance, tool angle, etc., making it difficult to process the frame after processing. Meet the process requirements. And even if you want to improve it, there is a certain degree of difficulty.

But now after using water jet stone cutting machine, both the process and the result are completely different, and it cannot overcome the limitations in many aspects, and at the same time, it can maintain the consistency of the part size. In addition, the efficiency of the entire processing process is also very high, and there are also significant advantages in saving materials.

When the equipment reaches a certain pressure, the water will flow out from the nozzle of the water cutting machine and shoot at the object at a super high speed, thus causing an impact on it. However, when the impact occurs, it will also cause a sudden change in the jet velocity, which will cause a sudden change in the internal pressure of the water droplet and the internal stress field of the contact point material, and cause damage to the object.

That is to say, in fact, the interaction between the water jet droplet and the object is mutual. When the droplet acts on the surface of the object, the jet can only remain flat in the stage, and once it touches the solid material, it will move freely radially. From this, it can be proved that the speed of the water jet basic object in the water jet stone cutting machine changes in an instant.

After scientific progress has developed more and more equipment, the cutting operations of various products can be completed more easily. As far as stone is concerned, this is a material that is difficult to process, but with the water jet stone cutting machine with the emergence of equipment such as stone, it is also possible to process stones arbitrarily and use them.

In the entire field of stone processing, the water jet stone cutting machine is responsible for the sawing and processing of materials, and it has been significantly improved in terms of cutting quality, cutting efficiency and cutting cost. Water jet stone cutting machine have also shown important talents in this regard, providing cutting convenience for the manufacturing industry.

In addition to cutting, stone may also undergo grinding and polishing, special-shaped processing, etc., all of which rely on advanced machine tools to achieve. If only manual operation is used, not only the efficiency is low, but also the machining accuracy is not ideal. It can be seen that for hard materials such as stone, the use of mechanical equipment is even more essential.

Can you cut stone with a water jet?

Yes. It is possible to cut any type of stone using waterjet technology. Water jet cutting is one the most common industrial cutting methods for engineered stone, thick granite, marble, and even other materials that aren't stone, such as glass, metals, and plastics.

How thick can a water jet cutting machine cut?

Waterjet cutters can make cuts of between 25-30 cm (10-12 inches) in hard materials. It is possible to cut thicker material, but it reduces cutting speed. If you have a lot of time on your hands, there is no limit to the material you can cut with a water jet cutter.

What Cannot be cut by waterjet?

A water jet would not cut through diamond or tempered glass – with tempered glass the material would break as designed to when force is applied.

wwaterjet

wwaterjet