The difference between water jet marble cutting machine cutting and ordinary cutting

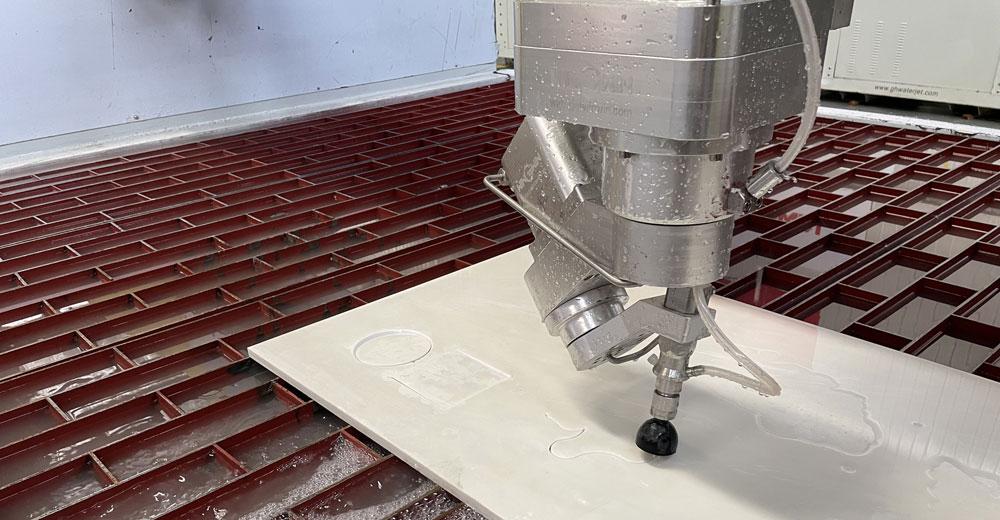

The difference between these two cutting methods is very large. Although the cost of water jet marble cutting machine cutting is relatively high, the edges cut by water jet are basically as neat as the edges of purchased tiles, while the edges of ordinary cut areas They are all stubble-like. If you say that you can see the jagged edges when pasting.

Waterjet-cut edges of ceramic tiles for cleanliness and cleanliness. The edges of the purchased tiles are basically approximate, very smooth and flat, while ordinary cutting has stubble and burrs, so most of the ordinary cutting is used on the edge, and then covered with skirting. Otherwise, the gap will look like a burr.Water jet marble cutting machine can perform one-time cutting of any material with any curve, and ordinary cutting methods are limited by the variety of materials.

Water jet marble cutting machine does not generate heat and harmful substances, and the material has no thermal effect (cold cutting). Ordinary cutting produces dust and other substances. After Water jet marble cutting machine cutting, no secondary processing is required or easy, safe, environmentally friendly, low cost, fast, high efficiency, can realize the cutting process of any curve, convenient and flexible, and widely used.

Water jet marble cutting machine of cutting glass, ceramics, stone and other materials

Waterjet is widely used in the industry, especially in various cutting operations in the fields of glass and ceramic stone. For these different cutting objects, waterjet also has its own unique operation schemes. Let’s get familiar with them together.

In today's society, with the development of glass, ceramic and stone industries, people also put forward more demands for oxidation of such products, so it can only be realized through superb cutting technology. For flat materials, the water jet marble cutting machine can process various geometric figures under the control of the program, while the ordinary cutting method can only achieve straight line cutting.

Moreover, heat is also generated during the cutting process, so there is no need to worry about arc marks. Using water jet cutting will only be safer and more environmentally friendly. In addition to some graphics, water jet marble cutting machine can also complete modeling and drilling operations, which does not require the use of molds, which is more convenient, simple and flexible. It is this advantage that makes glass products, ceramic products, and stone paper pieces better reflected.

How to realize the slit compensation in the cutting of the water jet marble cutting machine

Waterjet is one of the most important equipment in the cutting field, in addition, CNC cutting machine is also a very critical cutting equipment. The introduction is the slit compensation process of water jet marble cutting machine to effectively solve various difficulties in the cutting process.

Kerf compensation is mainly a kind of correction processing for the machining accuracy of water jet marble cutting machine on the process drawing, which can effectively solve the problem of difficult cutting. When the CNC laser cutting machine cuts materials, the trajectory and route of cutting according to the CNC instructions are generally theoretical values. In addition, there are slits during cutting, so there will be errors in the actual cutting size. Therefore, compensation is required to overcome the dimensional error of the workpiece and ensure that the actual cut part size meets the requirements.

Commonly used kerf compensation is divided into software compensation and numerical control system compensation. When software compensation is used, only the programming parameters need to be input, and the geometric dimensions can be automatically offset when the numerical control code is generated. In this case, there is no need to perform compensation on the CNC system to avoid duplication. In the process of compensation through the numerical control system, the compensation amount in the software needs to be set to zero, otherwise there will be deviations.

How much does water jet marble cutting machine cost?

Typically, water jet marble cutting machine cost per hourly rate lies somewhere between $12 to $30 per hour. Of course, in specific requirements, this number can go higher or lower.

Can you cut marble with water jet marble cutting machine?

water jet marble cutting machines can cut 12 inches of the hardest stones like granite, marble, and quartz at high speed.

Why are water jet cutters so expensive?

Consumable materials such as water, fuel, and abrasive material also add to the overall expense. That's the raw expense alone. The pressure level also increases the cost significantly. Thicker materials require more power to cut, and it also needs more time.

So if you want to choose the right water jet marble cutting machine to benefit your business,Please choose WIN-WIN water jet marble cutting machine. It can meet your demand and improve accuracy of your processing production in the same time.

wwaterjet

wwaterjet