Why we use abrasive water jet cutting machine

Everyone should know how hard the ore is. It is difficult to process it with general equipment, but water can solve this difficulty. The water we are talking about here is actually a water jet, which is a cutting process, which is done with ordinary water. In the field of cutting, there are really many process options, such as chainsaw, laser, arc, etc., but why do people particularly favor abrasive water jet cutting machine?

In contrast, the hardness of ore is higher than that of many metal materials, but this will not affect the use of abrasive water jet cutting machine. Under high pressure, ordinary water can have magical power, enough to cut all hard materials. Moreover, there will not be various dangerous factors like other methods, and it will not be damaged by high temperature, and there will be no dust. All aspects can prove its environmental protection.

It can be seen that water is not only the source of life, but also combined with high technology to shine in the medical, metal cutting, food and mining industries to complete the operations required by users.

From the perspective of the gap, the incision of the general abrasive water jet cutting machine is about 1.0mm to 1.2mm, and it will change with the diameter of the sand cutter tube. Viewed from the beveled side, the quality of abrasive water jet cutting machine in this aspect is also quite good. Most of the beveled edges on one side of the cutting parts we have seen can reach about 0.1mm, which meets the standard requirements.

To inspect the quality of water jet cutting machine, we should start from the observation of oil leakage

Abrasive water jet cutting machine is one of the important equipment in the cutting field, but nowadays there are more and more abrasive water jet cutting machine manufacturers, and we can't tell which one is which. Someone said it's not easy? The quality of the product cannot be fully reflected from the technical indicators of the abrasive water jet cutting machine, but in fact these factors are not very meaningful for judging the quality of the equipment.

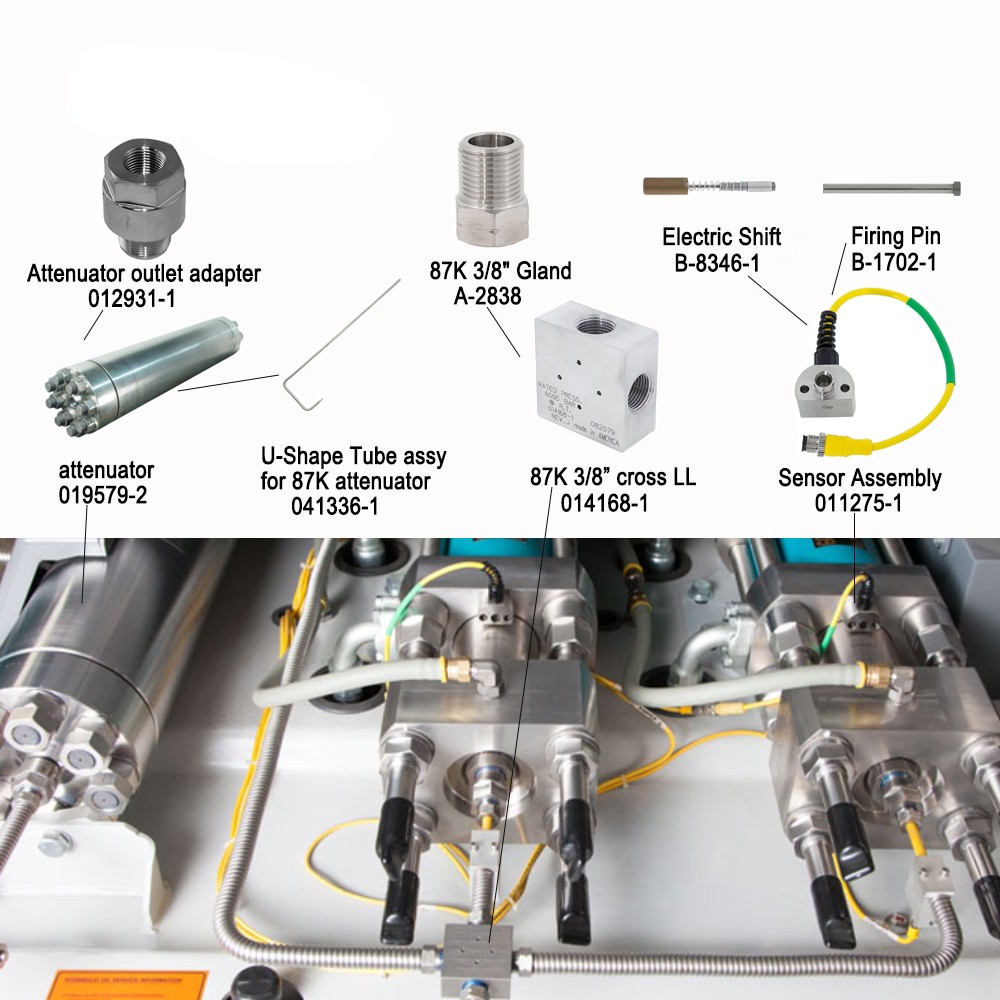

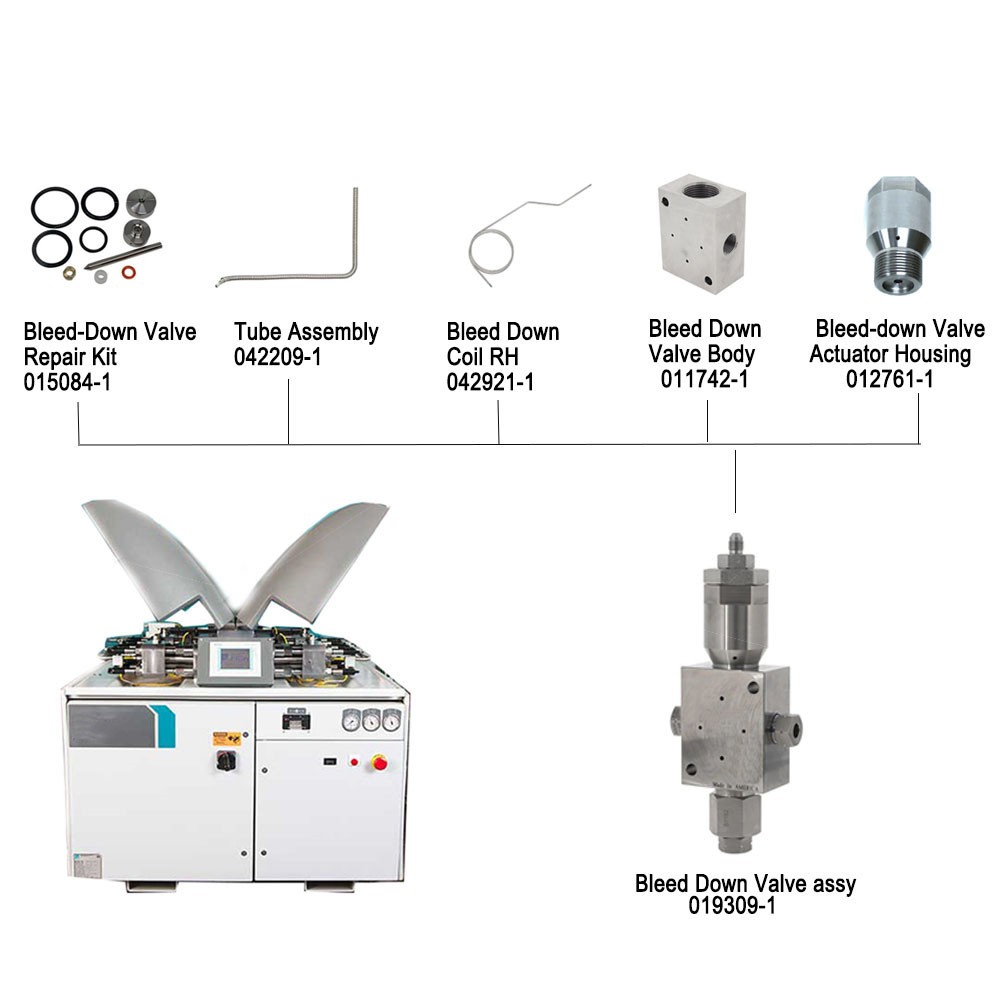

If you want to inspect the abrasive water jet cutting machine, you have to start with looking at the oil. For the equipment, the realization of the function mainly depends on the high pressure, so the quality of the intensifier must be checked first, and the quality of the intensifier is judged from its leakage. Started with the oil situation. Nowadays, many abrasive water jet cutting machines adopt the dual intensifier type. This structure is good, but the requirements are also very demanding. We should be careful, or it may cause oil leakage.

The actual inspection is very simple, just start the abrasive water jet cutting machine and run it for a period of time, pay attention to observe its oil leakage. If there is no oil leakage after more than 200 hours of use, it shows the working performance of the intensifier, and such equipment can be used with confidence.

What are the frequently damaged parts during the use of waterjet?

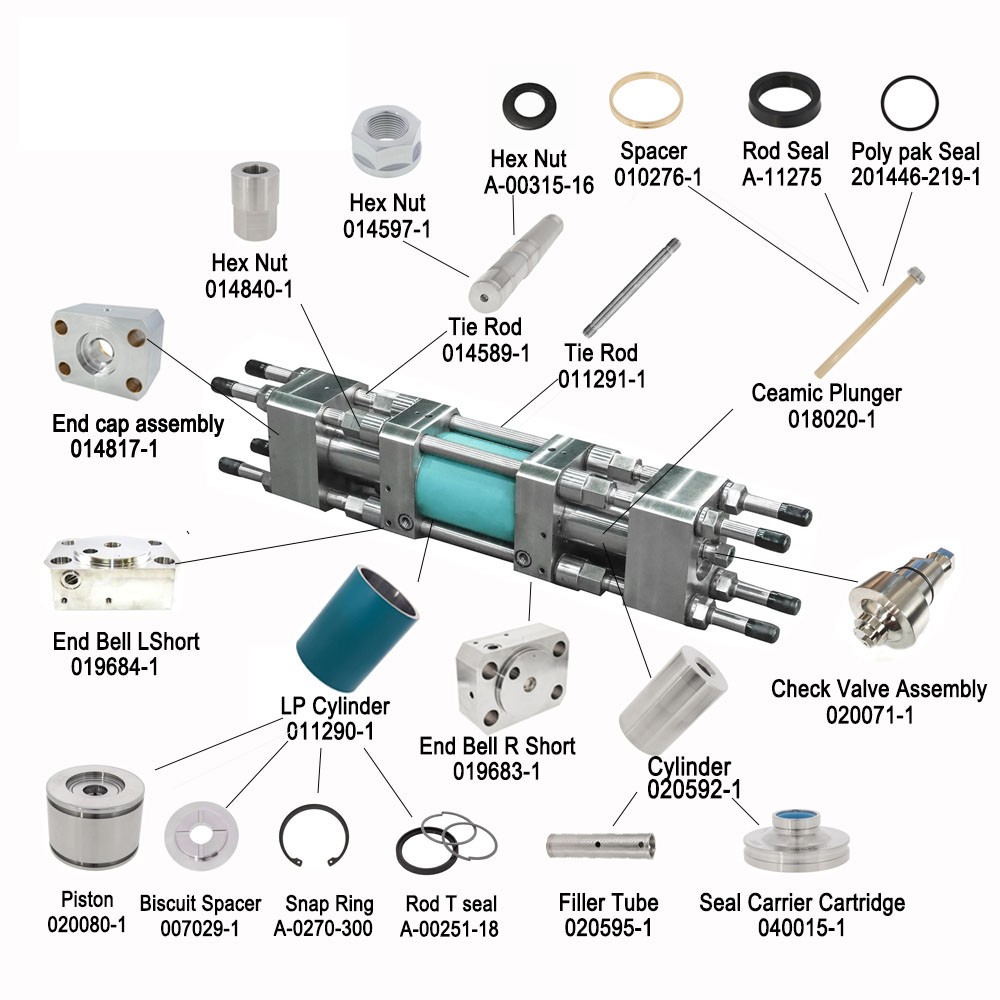

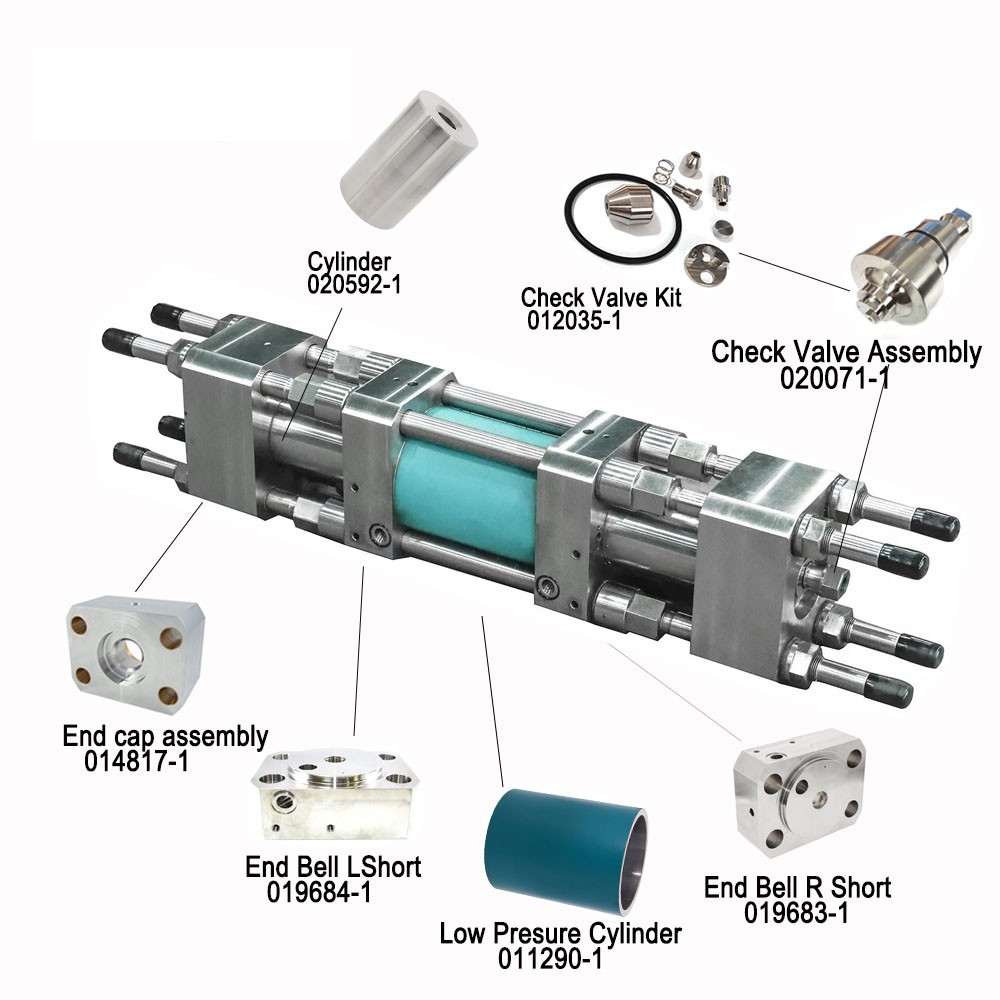

Abrasive water jet cutting machine is a kind of cutting equipment, which has no restrictions on various materials, which makes it widely used in various industries. In the whole equipment, nozzle tubes and diamond orifices are the most critical and easily damaged parts, and most of them are caused by the erosion of water flow on them. Especially in the case of long-term use, both the nozzle tubes and diamond orifices will be deformed, which will eventually affect the cutting effect.

In addition, the seals in the water jet will often break down. For the above-mentioned common vulnerable parts of the water jet, you must pay attention to observation at ordinary times, and replace them in time if there is any abnormality. In terms of understanding of water jet components, we should also remind everyone of its cooling problem. No matter what method is used, it must dissipate heat in time to avoid adverse effects on the water jet. So it is important to maintain your abrasive water jet cutting machine properly. In this way you can reduce the downtime of your machine.

What is abrasive water jet cutting?

Abrasive water jet cutting uses a high-pressure jet of water (typically 200–300 MPa) with an abrasive powder in suspension. The method is principally aimed at the cutting of holes or shapes in sheet material.

Which abrasive is used in abrasive water jet cutting machine?

The abrasive particle used for AWJM is usually silicon carbide and aluminum oxide. The abrasive particle is embedded to the water jet purposely to increase the MMR of the process.

How thick can an abrasive water jet cutting machine cut?

Abrasive water jet cutting machine can cut material from 1/16 inch to over 10 inches thick, in high or low volume.

wwaterjet

wwaterjet