Questions about water jet tile cutter you should know

The development of the intelligent era has also played a role in promoting the development of water jet tile cutter. A series of emerging products have emerged in the industry, and intelligent 5 axis water jet tile cutters are one of them. Let's take a look at the advantages of this smart device?

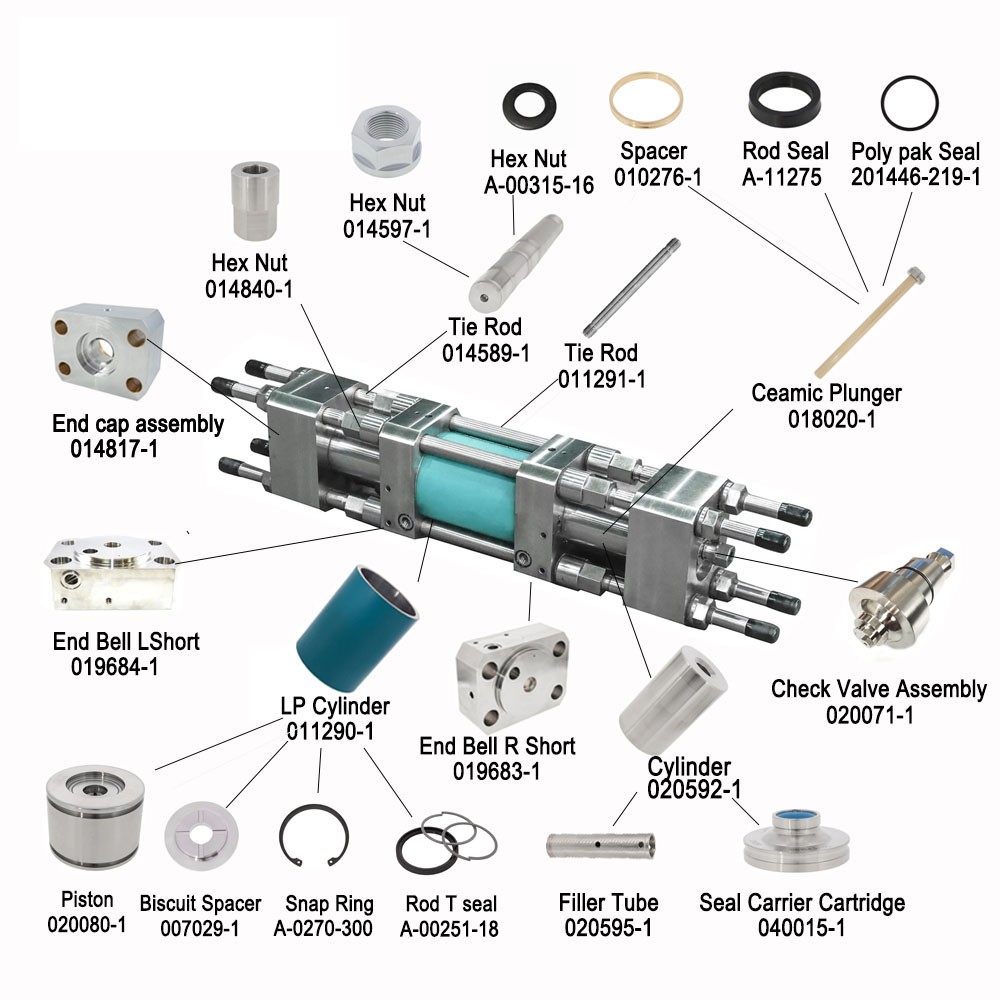

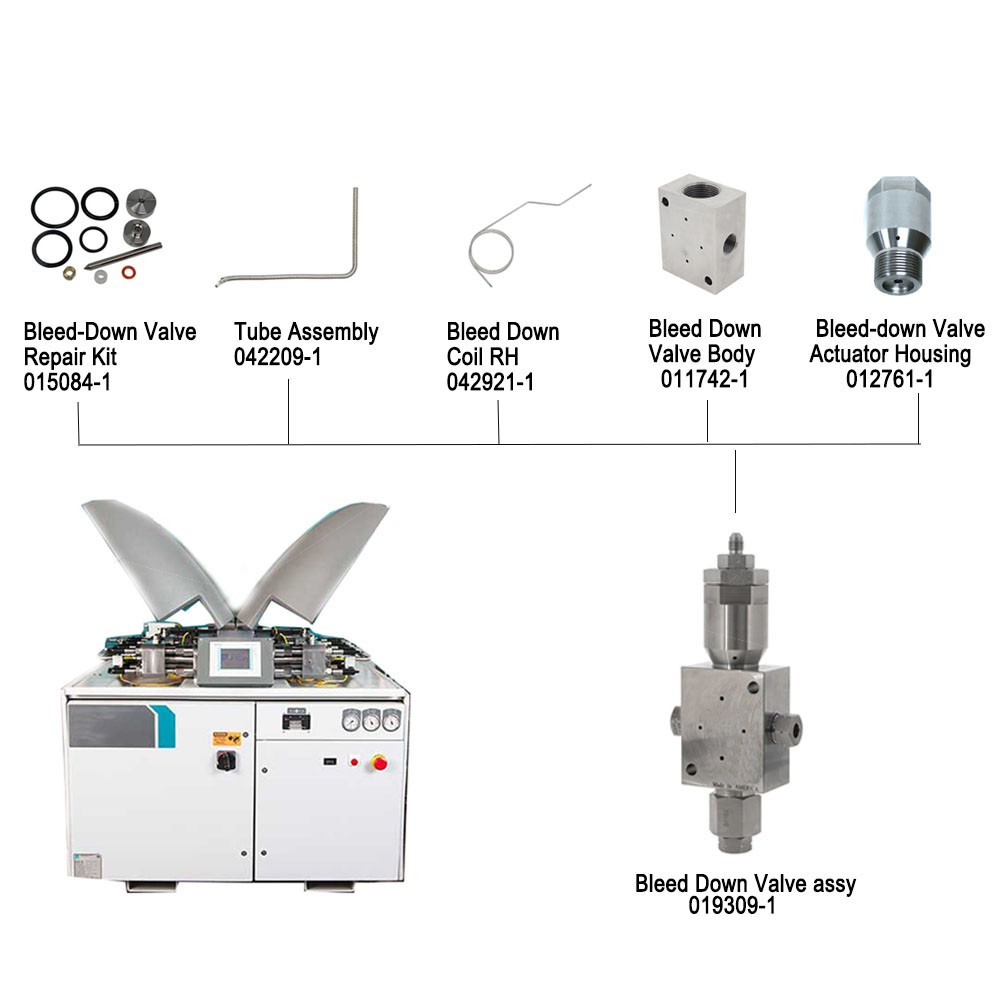

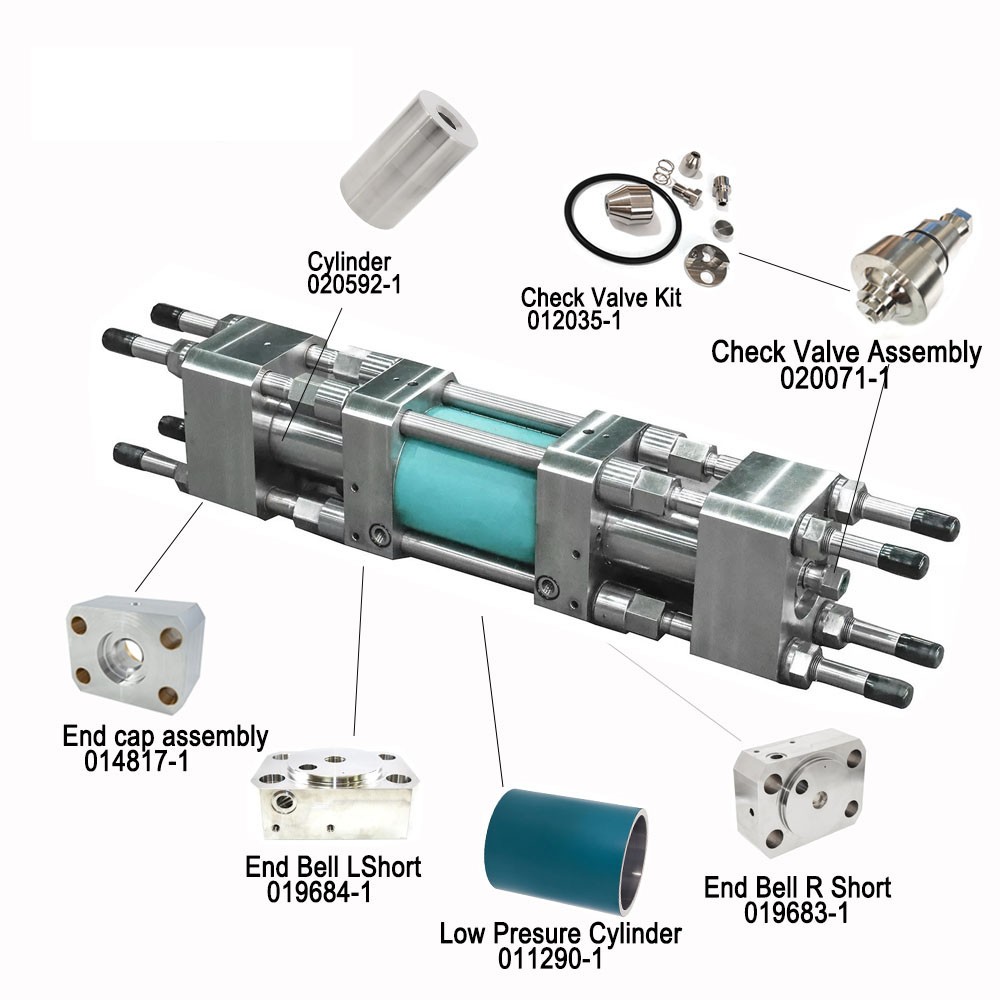

The ultra-high pressure intensifier pump is used in the 5 axis water jet tile cutter, which can better provide pressure for the water jet cutting equipment and help the equipment to achieve energy saving and environmental protection. In addition, the sealing system used in the cutting machine is also very good. It can not only play a good sealing role, but also protect each component to a certain extent, thereby prolonging its service life.

In addition, we have also equipped the 5 axis water jet tile cutter with an intelligent control system and a high-precision universal cutting head. The use of this system not only greatly improves the cutting efficiency of the waterjet, but also improves the cutting accuracy. The language has also been greatly improved to avoid errors.

The application of waterjet in the field of cutting is very extensive and has been recognized by the majority of users, but many people are not like this at the beginning, because they already have a thorough understanding of waterjet. You can also take a look at some questions about water jet tile cutter and how the profession answers them.

Is the cost of using the water jet high?

This is a problem that most users are concerned about, just do some calculations to know. If waterjet is used for cutting, the main costs include equipment costs, water and electricity costs, consumables costs and normal maintenance costs in the later period. In general, compared with some other cutting methods, the running cost of waterjet is still acceptable.

Is the water jet safe to use?

When producing products, manufacturers will put the safety of the equipment first. For example, safety devices such as safety holes and reinforcement components will be added to the water jet to avoid safety threats caused by excessive pressure of the water jet tile cutter.

Does the water jet make a lot of noise?

Any equipment will make some noise more or less when it is running, and the water jet tile cutter is no exception. But now some emerging water jets have paid more attention to this problem, and the noise problem has been alleviated through the adoption of technology.

Common sense of safe electricity use in water jet cutting operation

Water is definitely used in water jet tile cutter operations, but the operation of the equipment is inseparable from electricity, but if the enemy is together for two days, it will definitely be a bad thing, that is, it is easy to get an electric shock. Therefore, in order to prevent similar safety accidents, safety protection measures for water jet cutting operations must be in place.

For example, it is necessary to connect the ground wire during water jet tile cutter cutting, and at the same time, the ground wire and the cutting torch must be in the same direction, otherwise, not to mention easy to get an electric shock, it will also cause corrosion of the equipment and affect its service life. It should be noted that if the cutting strip or cutting wire is to be replaced during the cutting process, it must be ensured that the operation is in the state of power cut off.

We need to have basic safety awareness and master some knowledge about safe use of electricity. Moreover, the insulation and water tightness of the equipment used for cutting must also undergo strict inspections and be in a qualified state.

Can you cut tile with water jet tile cutter?

Definitely. Water jet tile cutter can not only cut tiles; it gives you the best results. In fact, a water jet tile cutter can handle any type of tile you use.

Is water jet cutting good?

A major advantage of waterjet cutting is that no heat affected zone (HAZ) occurs due to its cold cutting method. Not only does cold cutting enable clean cuts, but also increases the operators' safety significantly by eliminating the risks of burns.

How much does waterjet cutting cost?

Typically, water jet tile cutter cost per hourly rate lies somewhere between $12 to $30 per hour. Of course, in specific requirements, this number can go higher or lower.

So if you want choose a water jet tile cutter which is suitable for your business. Please choose WIN-WIN water jet. We have a broad experience in water jet cutting industry. We believe that we can help with your water jet problem and design the right water jet tile cutter for you.

wwaterjet

wwaterjet