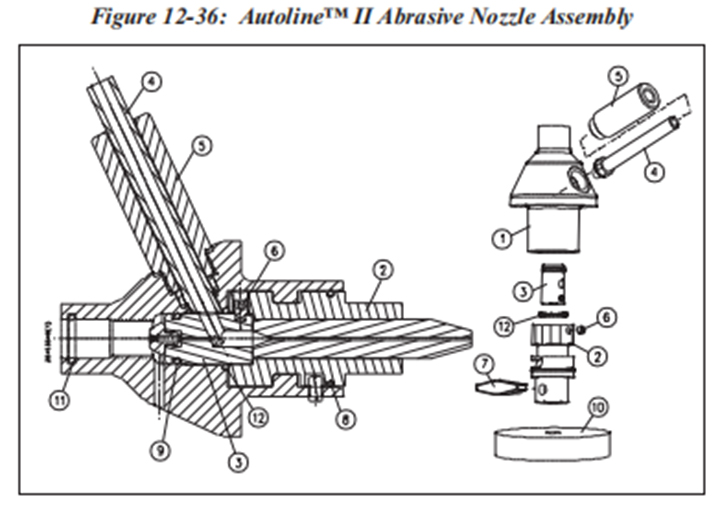

Table 12-46 Autoline™ II Abrasive Nozzle Assembly | |||

Item | Part Number | Description | Quantity |

20453949 | AutolineTM II Nozzle Assembly, .030 Wear Insert | ||

20454108 | AutolineTM II Nozzle Assembly, .043 Wear Insert | ||

1 | 20453952 | Nozzle Cap | 1 |

2 | 20453958 | Nozzle Body | 1 |

3 | 20453064 | Wear Insert, .030 x .156 | 1 |

20453082 | Wear Insert, .043 x .156 | ||

4 | 20453964 | Feed Tube Assembly | 1 |

20453967 | Feed Tube | ||

10142610 | O-Ring, .19 x .31 x .06 | ||

20453970 | Washer | ||

5 | 20453973 | Handle | 1 |

6 | 20433398 | Setscrew, 8-32 | 1 |

7 | 20453976 | T-Knob | 1 |

8 | 05138821 | O-Ring, .69 x .81 x .06 1 | |

9 | 20445476 | O-Ring, .31 x .44 x .06 | 1 |

10 | 05087168 | Guard | 1 |

11 | 05081518 | O-Ring, .38 x .50 x .06 | 1 |

12 | 05077078 | O-Ring, .38 x .50 x .06 | 1 |

49885361 | Poly Tube, .38 | ||

The Waterjet Autoline™ II Abrasive Nozzle Assembly is a component used in waterjet cutting systems specifically designed to handle abrasive materials during the cutting process. It's a critical part that injects abrasive particles into the high-pressure water stream before it exits the cutting head.

Key features and functions of the Waterjet Autoline™ II Abrasive Nozzle Assembly include:

1. Abrasive Mixing: This assembly mixes the abrasive material (such as garnet) with the pressurized water just before it exits the nozzle. The precise mixing ensures an effective abrasive-water mixture for cutting various materials.

2. Nozzle Design: The nozzle assembly is engineered to withstand the abrasive nature of the materials being cut, maintaining durability and ensuring a consistent abrasive flow into the water stream.

3. Precision Cutting: By delivering a controlled and accurately mixed abrasive-water stream, this nozzle assembly contributes to precise and clean cutting of materials such as metals, stone, glass, and composites.

4. Compatibility: The Autoline™ II Abrasive Nozzle Assembly is designed to be compatible with specific waterjet cutting systems and may offer customization options to suit different cutting needs.

5. Durability and Maintenance: These assemblies are constructed with materials that offer longevity and resistance to wear from abrasive materials. Regular maintenance ensures optimal performance.

Overall, the Waterjet Autoline™ II Abrasive Nozzle Assembly plays a crucial role in enhancing the cutting performance of waterjet systems by efficiently injecting and controlling the flow of abrasive materials, resulting in precise and efficient cutting of various materials.

wwaterjet

wwaterjet