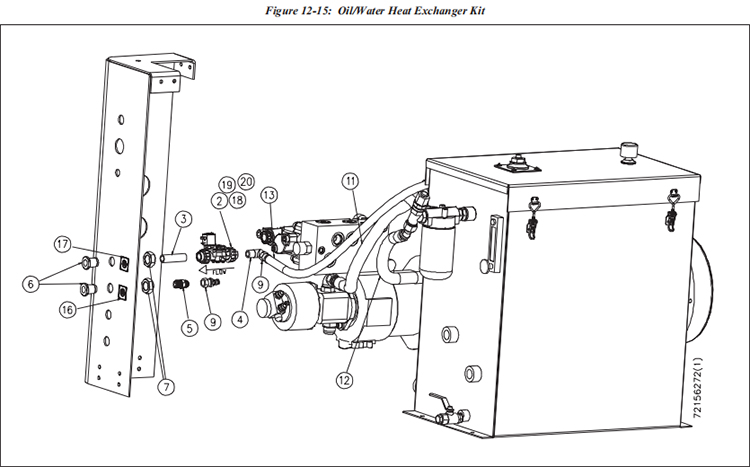

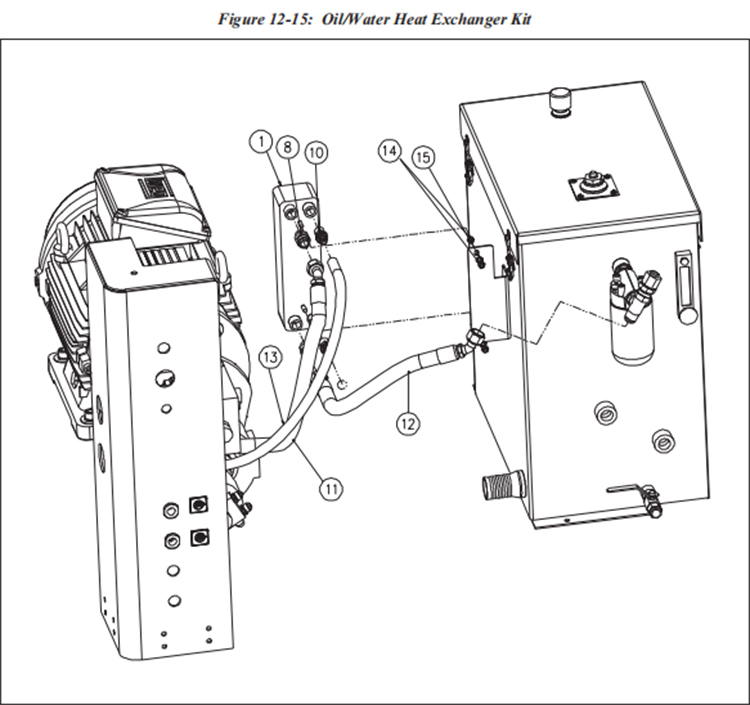

Table 12-15 Oil/Water Heat Exchanger Kit 72156272 | |||

Item | Part Number | Description | Quantity |

1 | 05145958 | Heat Exchanger | 1 |

2 | 72153174 | Solenoid Valve | 1 |

3 | 10084770 | Pipe Nipple, .50 x 2.0 | 1 |

4 | 95680922 | Adapter, JIC/Pipe, .50 x .50 | 1 |

5 | 95157418 | Adapter, JIC/Pipe, .50 x .50 | 1 |

6 | 49886922 | Bushing, Bulkhead, .50 x .50 | 2 |

7 | 10070092 | Jam Nut, 1-14 | 2 |

8 | 05073150 | Adapter, JIC/ORB, .75 x .63 | 2 |

9 | 10173805 | Adapter, Hose/JIC, .50 x .50 | 2 |

10 | 10079713 | Hose Barb, .50 x .50 | 2 |

11 | 20456208 | Hydraulic Hose Assembly, .75 x 28.0 | 1 |

12 | 20468826 | Hydraulic Hose Assembly, .75 x 23.0 | 1 |

13 | 20421272 | Hose, Push-on, .50 | 65.0" |

14 | 10070191 | Hex Nut, M8 | 4 |

15 | 10069672 | Lock Washer, M8 | 2 |

16 | 10150472 | Decal, Cool In | 1 |

17 | 10150480 | Decal, Cool Out | 1 |

18 | 72153182 | Connector, DIN | 1 |

19 | 72135884 | Cable Assembly | 1 |

20 | 7215853 | Adapter, Pipe/Solenoid Valve | 2 |

A waterjet oil/water heat exchanger kit is a component within a waterjet cutting system designed to regulate the temperature of hydraulic oil or water used in the system. It helps maintain optimal temperatures to ensure the efficient operation and longevity of various hydraulic components, such as pumps, motors, and other parts sensitive to temperature fluctuations.

Key features and functions of an oil/water heat exchanger kit in a waterjet cutting system include:

1.Heat Exchange Mechanism: The kit consists of a heat exchanger device designed to transfer heat between the hydraulic oil and water, regulating their temperatures. It facilitates the transfer of heat from one fluid medium to another, allowing for efficient cooling or heating as needed.

2.Cooling or Heating Elements: Depending on the system's requirements, the heat exchanger kit might incorporate elements for either cooling or heating the hydraulic oil or water. Cooling elements, such as fans or coolant passages, dissipate excess heat, while heating elements may be utilized to maintain optimal operating temperatures in colder environments.

3.Control System: Some kits feature control systems, including temperature sensors and controllers, that monitor and regulate the temperature of the hydraulic oil or water within the system. These systems help maintain the desired temperature range for optimal performance.

4.Filtration and Contaminant Removal: In some setups, the heat exchanger kit may include filtration mechanisms to remove contaminants or impurities from the hydraulic fluid or water, ensuring clean and debris-free operation.

5.Piping and Connections: The kit incorporates piping, connectors, and hoses to facilitate the flow of hydraulic oil or water through the heat exchanger and the system, enabling effective heat exchange.

The primary function of the oil/water heat exchanger kit in a waterjet cutting system is to regulate and control the temperature of the hydraulic fluid or water, preventing overheating or excessive cooling, which could affect the system's efficiency or cause damage to components. By maintaining optimal temperatures, the kit helps ensure consistent performance and prolongs the lifespan of the system's hydraulic components.

wwaterjet

wwaterjet