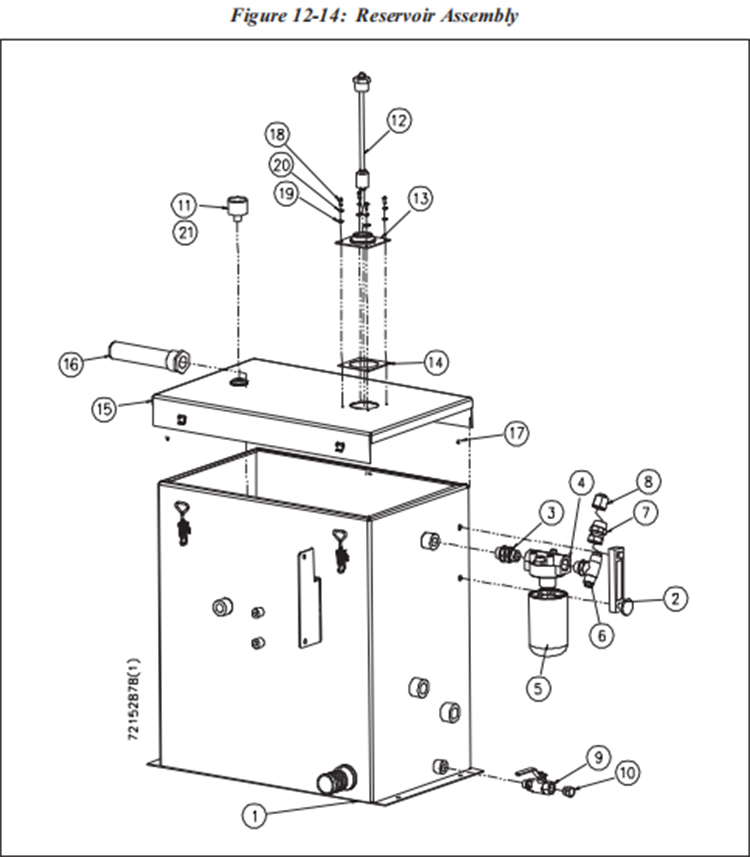

Table 12-14 Reservoir Assembly 72152878 | |||

Item | Part Number | Description | Quantity |

1 | 72152885 | Reservoir Weldment | 1 |

2 | 20451474 | Level/Temperature Gauge | 1 |

3 | 05057542 | Coupling, ORB, .75 x .75 | 1 |

4 | 05049697 | Hydraulic Filter Head | 1 |

5 | 05049689 | Filter Element | 1 |

6 | 05071063 | Tee, JIC/ORB, .75 x .75 | 1 |

7 | 05079371 | Adapter, BSPP/JIC, .75 x .75 | 1 |

8 | 05069976 | Cap, JIC Swivel, .75 | 1 |

9 | 20423326 | Ball Valve Assembly | 1 |

10 | 05025176 | Plug, ORB, .50 | 1 |

11 | 05092739 | Air Breather | 1 |

12 | 72145376 | Temperature/Level Sensor | 1 |

13 | 72138699 | Reservoir Cover | 1 |

14 | 05079967 | Gasket | 1 |

15 | 72153711 | Reservoir Weldment, Cover | 1 |

16 | 80087687 | Diffuser | 1 |

17 | 72118430 | Gasket | 78.0" |

18 | 95897948 | Button Head Screw, 10-24 x 1/2 | 4 |

19 | 95367207 | Flat Washer, #10 | 4 |

20 | 95367728 | Lock Washer, #10 | 4 |

21 | 10082071 | Pipe Plug, .38 | 1 |

The waterjet reservoir assembly is an essential component within a waterjet cutting system responsible for storing, managing, and supplying water or hydraulic fluid to the high-pressure pump, as well as providing a controlled return path for the used fluid.

Key components and features of a waterjet reservoir assembly include:

1. Reservoir Tank: This is the main container or tank that holds the water or hydraulic fluid. It's designed to contain a specific volume of fluid required for the system's operation. The tank's size can vary depending on the system's needs and the volume of fluid required for consistent operation.

2. Inlet and Outlet Ports: These ports allow the flow of water or hydraulic fluid into and out of the reservoir. The inlet port receives the supply of fluid, while the outlet port directs the fluid to the pump or other parts of the system.

3. Baffles or Internal Components: The reservoir may have internal components like baffles or separators designed to help manage fluid flow, reduce turbulence, and prevent air entrapment in the fluid.

4. Filtration System: Some reservoir assemblies incorporate filtration systems to remove contaminants or debris from the fluid, ensuring the fluid remains clean and suitable for the cutting process.

5. Fluid Level Sensors: Sensors are often included to monitor the fluid level within the reservoir, providing feedback to the system's control mechanism and alerting operators when the fluid needs replenishing or maintenance

6. Cooling Elements: To regulate the temperature of the fluid, especially in high-intensity operations, the reservoir assembly might include cooling elements or systems to maintain optimal fluid temperatures.

The waterjet reservoir assembly ensures a consistent and reliable supply of water or hydraulic fluid to the high-pressure pump, maintaining the system's efficiency and performance during the cutting process. It also provides a controlled return path for used fluid, facilitating the recycling or disposal of the fluid after it has been utilized in the cutting operation.

The design and functionality of the reservoir assembly are critical to the overall effectiveness of the waterjet cutting system, ensuring the proper management and circulation of fluid within the system while maintaining cleanliness and operational efficiency.

wwaterjet

wwaterjet