Poduct Description

Dialine Diamond Orifice waterjet cutting head parts for water jet cutting machine

Item number: 1-12749-xx

Dialine - 1-12749-004 .004" Diamond WaterJet Orifice

Dialine - 1-12749-005 .005" Diamond WaterJet Orifice

Dialine - 1-12749-007 .007" Diamond WaterJet Orifice

Dialine - 1-12749-008 .008" Diamond WaterJet Orifice

Dialine - 1-12749-009 .009" Diamond WaterJet Orifice

Dialine - 1-12749-010 .010 inch Diamond WaterJet Orifice

Dialine - 1-12749-011 .011" Diamond WaterJet Orifice

Dialine - 1-12749-012 .012" Diamond WaterJet Orifice

Dialine - 1-12749-013 .013" Diamond WaterJet Orifice

Dialine - 1-12749-014 .014" Diamond WaterJet Orifice

Dialine - 1-12749-015 .015" Diamond WaterJet Orifice

Dialine - 1-12749-016 .016" Diamond WaterJet Orifice

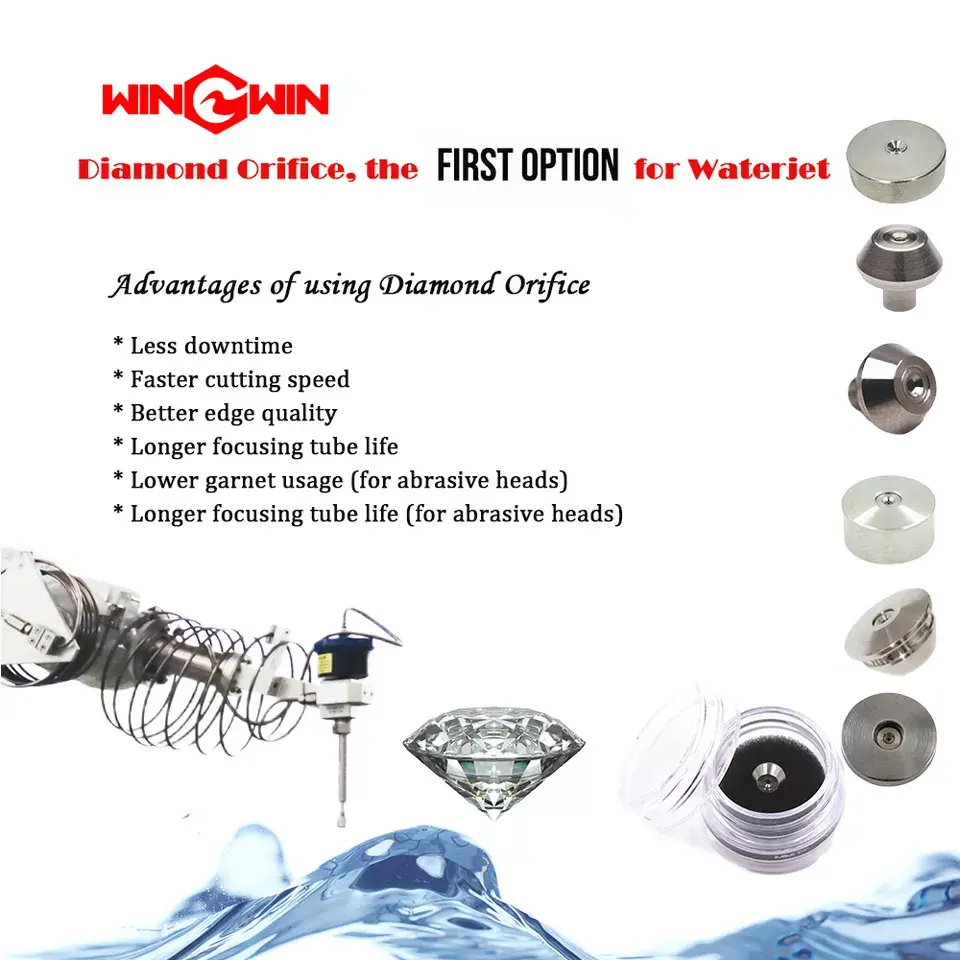

Features for Diamond Orifice:

1. The service life is as long as 1500-2000 hours

2. The strongest material on earth, Mohs hardness scale 10

3. Zero degradation on the edge of the inner diameter of the hole

4. Highest cutting precision and orifice quality

5, Maximum cutting speed, reduce downtime and improve work efficiency

7. Extend the service life of parts around the cutter head

8. High pressure, high cutting efficiency, reduce the amount of garnet

9. Superior borehole alignment accuracy and optimum water jet length

11. Excellent cutting performance, smooth cutting, significantly reduced tolerance, pressure up to 90000psi

14. One-time molding, non-stop, suitable for long-term continuous cutting

15. Reduce the workload of replacing the orifice plate

Waterjet nozzles come in various sizes and configurations, which are chosen based on the specific application and cutting requirements. The size of waterjet nozzles refers to the diameter of the orifice—the opening through which the high-pressure water or abrasive mixture exits the nozzle.

Typically, waterjet nozzles are available in sizes ranging from around 0.004 inches (0.1 mm) to larger diameters, such as 0.040 inches (1.016 mm) or more.

The choice of nozzle size depends on several factors:

Material Type and Thickness: Different materials and varying thicknesses require specific nozzle sizes to optimize cutting performance. Thicker materials might require larger orifices to accommodate higher flow rates.

Precision and Cutting Speed: Smaller nozzles are often used for precision cutting, intricate designs, or fine detailing. Larger nozzles might be used for faster cutting of thicker materials.

Abrasive Use: When abrasive material is added to the waterjet stream for abrasive waterjet cutting, nozzle sizes may differ to accommodate the flow of both water and abrasives effectively.

Pressure and Flow Rate: The nozzle size affects the flow rate of the water or abrasive mixture passing through it. Different nozzle sizes can handle varying pressure levels and flow rates.

Cutting Quality: Nozzle size influences the quality of the cut, including factors like edge finish, taper, and accuracy. Smaller nozzles often provide finer cuts with less taper, especially in thinner materials.

System Compatibility: Nozzle size should match the specifications and capabilities of the waterjet system, considering factors like pump pressure and nozzle compatibility.

Waterjet nozzles are interchangeable components that can be selected and changed based on the specific requirements of each cutting task. Choosing the right nozzle size is crucial to achieve the desired cutting results in terms of precision, speed, and quality for a particular material and thickness.

Contact WINWIN waterjet,we have all the orifices you need in stock,we can ship to you within one day delivery time.

If you have want to know more details of WINWIN waterjet orifices.please feel free to send us the inquiry,we will get back to you within 24 hours.

wwaterjet

wwaterjet