Waterjet Cutting Cell | Technology by Shape Process Automation

| 1 | Brand of robot arm: | ABB | |

| 2 | Model: | 1600 | |

| 3 | Style: | Ceiling | |

| 4 | Quantity of robot arm: | Tripple | |

| 5 | Application: | Automotive interior cutting | |

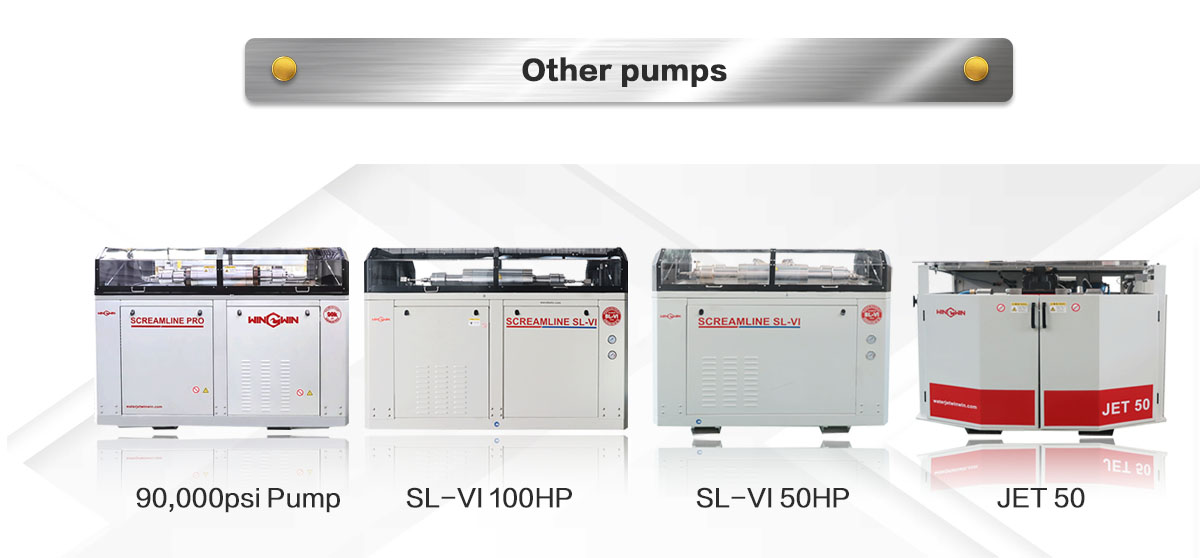

| 6 | Pump type: | Customized STREAMLINE SL-VI 100HP | |

| 7 | Oprator required: | 2 sets | |

| 8 | Customize avialable: | Yes | |

| 9 | Including devices: | Robot arm, cutting table, high-pressure pump, chiller, control system, etc.. | |

This Robot waterjet cutting solution is a ceiling type.Double robot arms structure.Equipped with a rotating table.Which is also the most commonly used structure in combination. It performs well in terms of efficiency, failure rate, safety, operation, etc.

This solution is basically suitable for cutting interior parts of all small cars to design a new robot waterjet cutting workstation solution and provide corresponding equipment to replace the existing old waterjet cutting cell in the customer’s factory to improve the processing efficiency of automotive interior carpets. , reduce maintenance costs.

The following are core configuration the advantages of this robotic water cutting structure:

Configuration of Robot Waterjet Cutting

Pressure: 360MPa-420MPa

Features: Each robot integration is equipped with a rotating table, and a new robot integration system can be added at any time. The floor space is relatively small, and the hanging manipulator cuts efficiently.

1: Rotary Working Station

2: ABB 1600 robot arm

3: Equipped with SL-VI 50 HP intensifier pump

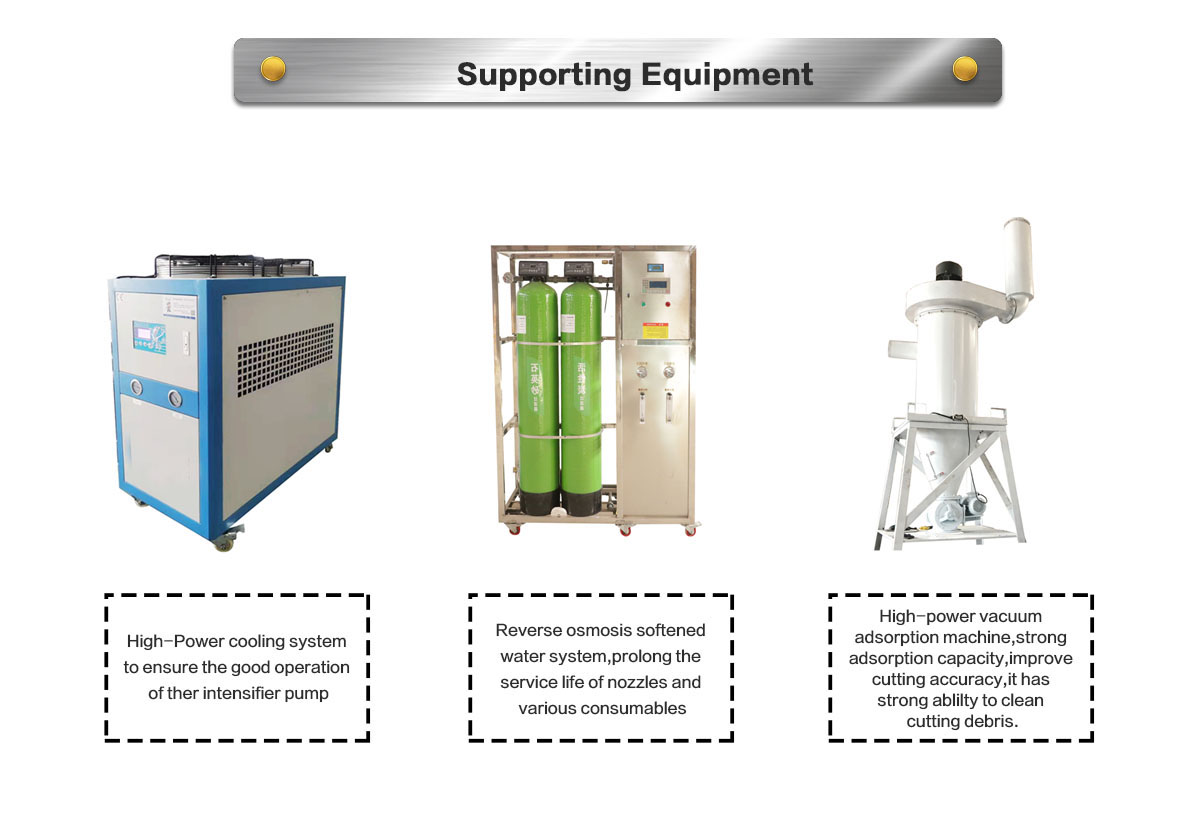

4: Industrial chiller

5: Vacuum adsorption system

6: Water purification system

7: Safety protection system

8: General control system

Advantages of Waterjet Pump

1. SL-VI 50HP pump has a double intensfier structure, which can be replaced for 24h operation without shutdown to ensure production efficiency

2. 60, ooopsi ultra high pressure, ensuring production efficiency

3. 3.8L/min water flow, which can drive 1-3 robots at the same time

4. Servo motor can save 30% cost

5. The intensfieri pump spare parts are universal

| Brand | WINWIN | Model | SL-VI 50HP |

| Name | Water jet servo motor pump | Temperature | 5-40°C |

| Working pressure | 420Mpa | Driving mode | Servo motor |

| Material | Material | Application | Water jet cutting system |

| Voltage | 380V | Rated power | 50HP |

| Attenuator capacity | 1L | Continuous working pressure | 320Mpa-380Mpa |

| Maximum water flow | 3.8L/min | Number of orifices | 3(0.17mm) |

| Tank volume | 150L | Size (L * w * h) | 2.2m*1.4m*1.6m |

| Weight | 1.5T |

The above is a complete set of robot waterjet cutting system. The usual industry is used to cut automotive interior materials.

In addition to customized Robot waterjet cutting.We also provide customers with industrial robots.

In the field of industrial robots, there are four major families: ABB, KUKA, FANUC, and YASKAWA. WINWIN waterjet is one of the designated agents of the four major robots.

With a total market share of more than 75%. The movement speed is fast.The trajectory is accurate.

the rigidity is good, the flexibility is high, and the stability is strong, which can shorten the processing time, speed up the production efficiency and reduce the labor cost.

So what is automotive interior?

Types of automotive interiors mainly include the following:

Seat belts, carpets, ceilings, steering wheels, seats, airbags.door panels, interior lighting, pillar panels, instrument panels, trunks (trunks).interior acoustic systems, air circulation systems, engine compartment interiors file system, etc.

Industrial robots also play an important role in automobile production, especially with the rapid development of the automobile industry.

Industrial robots can act autonomously and are widely used in different production links.Such as arc welding, spot welding, assembly, handling, painting.testing, palletizing , Grinding and polishing and other complex operations.

So a lot of robots are needed to complete the manufacture of a car. Industrial robots have become the key intelligent equipment in car production.

WINWIN can not only provide you with robot waterjet cutting projects and robot arms.But also this year we flew to countries all over the world to provide technical support and training for our customers.

Providing our customers with high-quality machines, mature technical support, timely and effective after-sales service.

Each machine has its own characteristics, if you also want professional and effective support from WINWIN, feel free to contact us!

wwaterjet

wwaterjet