Product Description

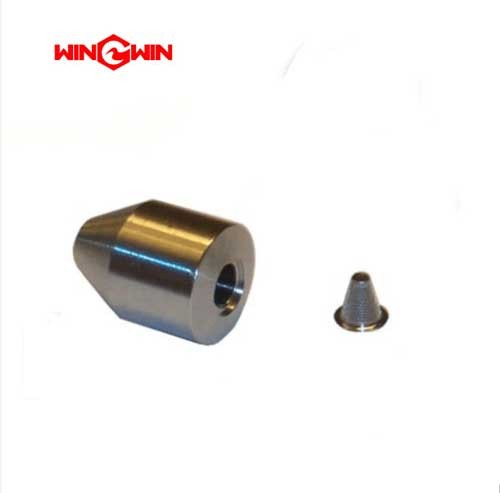

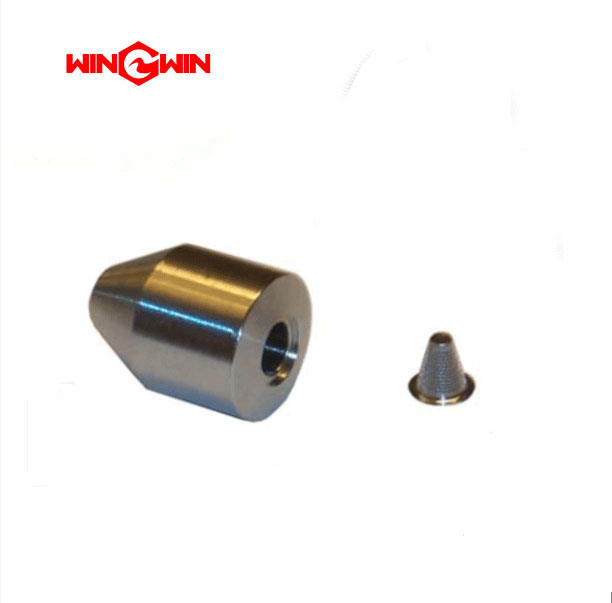

20454426 FILTER ELEMENT, .006"

Number: 20454426

Introducing: Short Stop Filter Element

KMT Waterjet Short Stop Filter Element, 60,000 psi - 90,000. Used with 20454363 - 60,000 psi Short Stop adapter and 20454366 - Short Stop adapter and in 90,000 psi applications

The robotic water cutting system has very strict requirements for water quality. Good water quality can protect the accessories of the high-pressure water system and extend the service life of each accessory.

For water quality treatment, the robotic water cutting manufacturer will install purified water at the front end of the entire system. Device, softened water treatment system is the basic requirement to ensure water quality. The treated softened water is called working water.

The path of working water passes through low-pressure water pumps, high-pressure pumps, high-pressure pipes and various joints, etc., in which a lot of water is produced. Impurities, such as precipitated scale, iron shavings after parts are worn, particles generated by aging of sealing devices, etc., these impurities will directly cause the nozzle to be clogged.

In order to prevent such failures from occurring, robot waterjet manufacturers will place in front of the cutting head, A high-pressure water filter device is added in the middle of the high-pressure pipe to block the physical particles generated in the middle and protect the nozzle. This high-pressure water filter element needs to be replaced regularly.

20454360 ADAPTOR INSERT, 1/4"

WINWIN waterjet Co.,Ltd. - Stable quality and preferential prices robotic waterjet parts supplier.

Pump Type Compatibility:

NeoLine,SL-IV 100hp Dual Topworks,

SL-IV 15hp-60hp,SL-IV 75hp-200hp,

SL-IV Plus 100hp Dual Topworks,SL-IV Plus 15hp-60hp,

SL-IV Plus 75hp- 200hp,SL-V100hp Dual Topworks,

SL-V 15hp- 60hp,SL-V75hp-200hp,SL-VI15hp-60hp,

SL-VI 75hp-200hp,TriLine

Win-Win Waterjet Co., Ltd was established by our engineer abdicate in research of Waterjet Cutting Technology for dozen years. He was the main director of Machinery Design Department in one of listed company, full experience on this domain.

In 2013, we broke into next step once again. There were many patents which applied by our technician team. And we has turned the research direction to Waterjet Cutting Robot Workstations.

In this year we started to serve major Automotive Interior Part Manufacturers. We built a maintenance team to solve any problems in scene, to make sure no delay on production in customers’ plant. In order to meet different purchasing ways in different countries.

Now WINWIN Waterjet has become the manufacture of robot waterjet cutting system ,robot waterjet seven axis cleaning system,abrasive waterjet cutting solution,90,000 psi ultra high pressure pump,100 HP large flow rate pump,60 HP dual intensifier pump, 50 HP waterjet pumps,.etc.We are a one-station solutions supplier.

If you wanna know the price of this part,please contact us for the quotation.

wwaterjet

wwaterjet